July 5, 2018

Making the Most Out of High Precision Mold Components

The benefits of high precision mold components for your business are endless. It would reap a larger increase in profit when the production process is done accurately. To achieve this, you should consider a partnership with a specialist in injection molding from China because they are the leading manufacturer of plastic components all over the world.

More than just quantity, the quality of high precision mold components marks the beginning of sustainable services. When you get the chance to discuss the design factors that are essential when developing your product, be keen in knowing how you can make the most out of high precision mold components.

Check out this article and find out why a high-precision injection mold leads to manufacturing success, together with the engineering standards of injection molding in China:

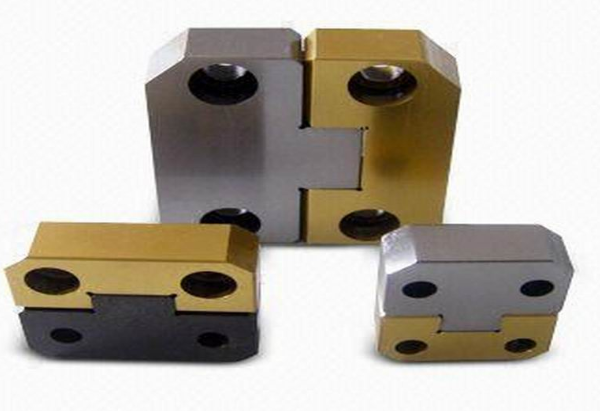

Of course, high-precision parts will begin with the mold. Building the tool will take a great deal of time and effort to achieve accuracy. It embodies the largest investment you can have for the manufacturing process. Using plastic injection molding to champion the manufacturing process of your products would require a critical perspective towards the end results of the project.

The goal of making high-precision parts in a large volume would be made possible by the complex tooling, which will be employed by an efficient injection molding company. So, when the plastic meets the mold – not only would it live up to the promise of an accurate customization – it would ensure the plastics will be of utmost quality, which you can deliver to your market.

There will be unforeseen plastic injection molding defects in the production process, but a molding company that has your best interests in their regard would do their best to prevent this from happening through innovative technologies from the software that design engineers use.

A modern CAD software will allow them to create cavities that are larger than the actual finished part which will accommodate the amount of resin shrinkage that may happen during the manufacturing process. The size of the cavities will serve as the allowance based on the specific properties of the resin. The shrinkage would make a huge difference in the overall design of the product. To prevent this from happening, your partner injection molding company can regulate the packing and holding rate in the mold.

This way, the mold components would be free from stress and shrinkage. As a result, the aesthetic and functional characteristics of the final output would meet the exact standards that you have set for the project.

Precision parts are accomplished by meeting the design standard specifically for the mold components. Gates must be properly and strategically placed to allow proper melt flow and pressure. The appearance of the part can be improved by positioning the gates in a hidden location on the part. You should also take into consideration the size of the gate which you can discuss with your partner molding company.

Make the most out of high-precision mold parts by multiplying its quantity to accommodate the high demand for your design. If you would rather pay much attention to the quality instead of the quantity, you can opt for family plastic injection molds which is a cost-efficient solution to the manufacturing process.

By designing the injection tool so that one mold contains different parts of a product, you can further utilize the potential of your high-precision mold components. Either way, plastic injection molding can improve your productivity for your output in a careful manner so that every production cycle is worthwhile.

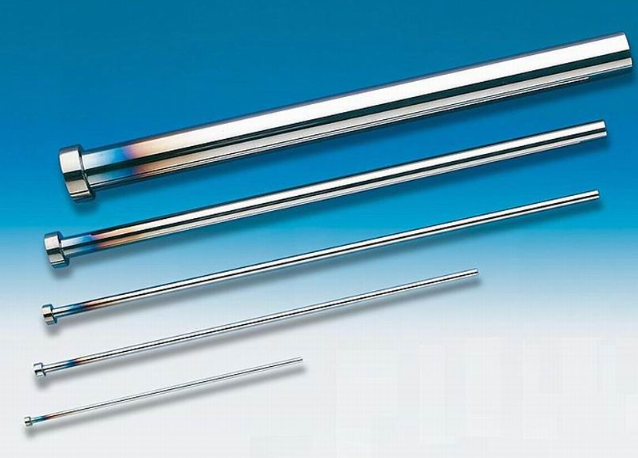

A quality injection mold is done because of an efficient and effective cooling system.

In order to do this, the molding company will ensure that the mold is maintained in a consistent temperature which will prevent shrinkage and warping in the part. On top of this, it will also minimize the cycle times to maximize the production output. Doing so will achieve a perfect balance that will result in a well-designed quality product.

Making sure that the part complexity is maintained all throughout the production process can be a daunting task. Part design, tool design, material selection, and manufacturing are the key factors that impact part quality.

You can request for running samples or prototype to avoid unnecessary rework of a mold cavity so you can also save time and money for the long-term process.

Having high precision mold components are vital when it comes to production. With your business on the line in terms of quality, you should have some peace of mind and know that the plastic parts will be manufactured with ease.

Quality precision molds are built to last years as an investment for your company and the many impacts it will deliver to your market is one of the few advantages that can stem from this industry.