What are the common types of rapid tooling used in injection molding China?

- 3D Printing in Plastic

- Direct Metal Laser Sintering

- Rapid Tooling Through Traditional Machining

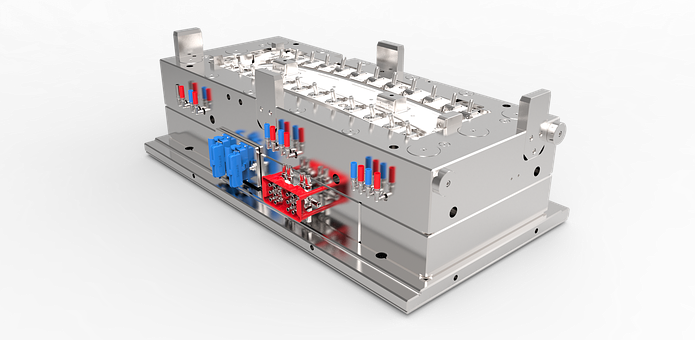

Injection molding in China is on top of the plastic manufacturing industry because when it comes to the maximum production quality of top-standard products, molding companies understand that their clients deserve only the best. Delivering the best results is possible with the rapid tooling system. To define rapid tooling: it is the creation of a plastic injection mold in a shortened timeline. The different rapid prototyping techniques are responsible for faster production processes and each one has a different benefit than the other.

Engineers began using rapid tooling in the 1990s because they wanted to speed up the injection molding process from its duration of weeks or months to an hour or just a few days. Having a rapid-tooled mold is ideal if you would want to test the waters of the production first by having a prototyping session with your partner China injection molding company.

With this, here are the common types of rapid tooling used in plastic injection molding which can help you in having a top-of-the-line process in a full-scale, high-volume production of plastic parts. Check them out below!

Source: 3dnatives.com

3D Printing in Plastic

3D printing is a versatile type of rapid tooling which has constantly been innovated and evolved that led to the process to be widely used in the industry. The advantages of 3D printing for plastic injection molding can be seen below:

With 3D printing in Plastic, you can allow the mold to be created extremely quickly. Depending on the efficiency of the tool, it can produce molds within a few hours. Not to mention that the molds are affordable as compared to printing in metal. The inexpensiveness can help you in adjusting your budget accordingly. Lastly, the machine has the ability to create any geometric part virtually, as required.

You should also keep in mind that 3D printing technology can be improved which why it can also be vulnerable to part tolerances. A prototype would be suitable to create using 3D plastic injection mold because of its reliability in speed and functionality.

Source: i.materialise.com/blog

Direct Metal Laser Sintering

You may have heard that metal is only used for rapid tooling through traditional machining but it can also be used to create a plastic injection mold and it does so by fusing together metal particles to make a solvent in a process which is called “sintering”. Rapid tooling uses the sintering process by spraying a cloud of powdered metal into a laser beam which will allow you to take control of the shape of your mold with the laser.

Direct Metal Laser Sintering can be done using a number of different metals, namely stainless steel, titanium, or cobalt chromium. The finished mold made of metal will be better equipped to handle the process of heat transfer, pressures, and ejection capabilities.

Sintering is a unique process because it allows you to print in conformal cooling line which helps the plastic to cool more rapidly. However, you should also consider that sintering can be expensive compared to rapid prototyping in plastic so that you can adjust production requirements around this fact.

Rapid Tooling Through Traditional Machining

The term “rapid tooling” is now applied to any tool that could be built quickly and this includes those molds that are created with traditional methods. The production process using this strategy can turn a mold into something tangible in just a matter of a few days to a week. This rapid tooling method is widely used because this is what molding companies have mastered throughout their stay in the industry.

This rapid tooling method is not at all perfect and it comes with limitations but that doesn’t mean that you shouldn’t adopt this type for your next project. It is limited in terms of geometry because you still need to cut a cavity of a shape and you cannot be freely choosing a cutter which means that you are stuck with the cutter that your partner company is using.

Fret not because you can address this issue by burning in the corner that you need through Electric Discharge Machining (EDM). If you would need a highly complex geometry for your mold, you should consider rapid tooling in traditional machining. You can also explore around the three common types of rapid tooling and see which one best suits your production needs.

Key Takeaway

The most common types of rapid tooling used in plastic injection molding all vary on technology, accuracy, consistency, and size. Whichever one you choose, they would of great help if you want to speed up the molding process. Rapid tooling processes can spell big benefits for your business and this can be reflected in production costs and time allowance.

With the advanced technology nowadays, especially those that are offered by molding companies in China, rapid tooling technology will generate higher productivity in molding. Ask your partner injection molding company about the rapid tooling system and how you can employ it to your prototyping process so that you can build a fully functional plastic prototype ready for a large-scale production.