April 9, 2025

China’s Plastic Mold Industry: Is It Right for Your Business?

Overview

- China’s injection molding machines market reached billions, highlighting the country’s leadership in cost-effective, high-quality plastic molding solutions.

- Chinese plastic mold makers offer advanced technology, skilled labor, and efficient production processes, making them ideal for businesses seeking precision and scalability.

- As a trusted plastic injection molding company in China, Richfields delivers expertise, quality, and cost-effective solutions tailored to global business needs.

Many businesses worldwide rely on China for high-quality, cost-effective plastic molding solutions. As a matter of fact, in 2024, the China injection molding machines market was valued at approximately $3.178 billion, reflecting the country’s strong manufacturing capabilities and global demand for its services.

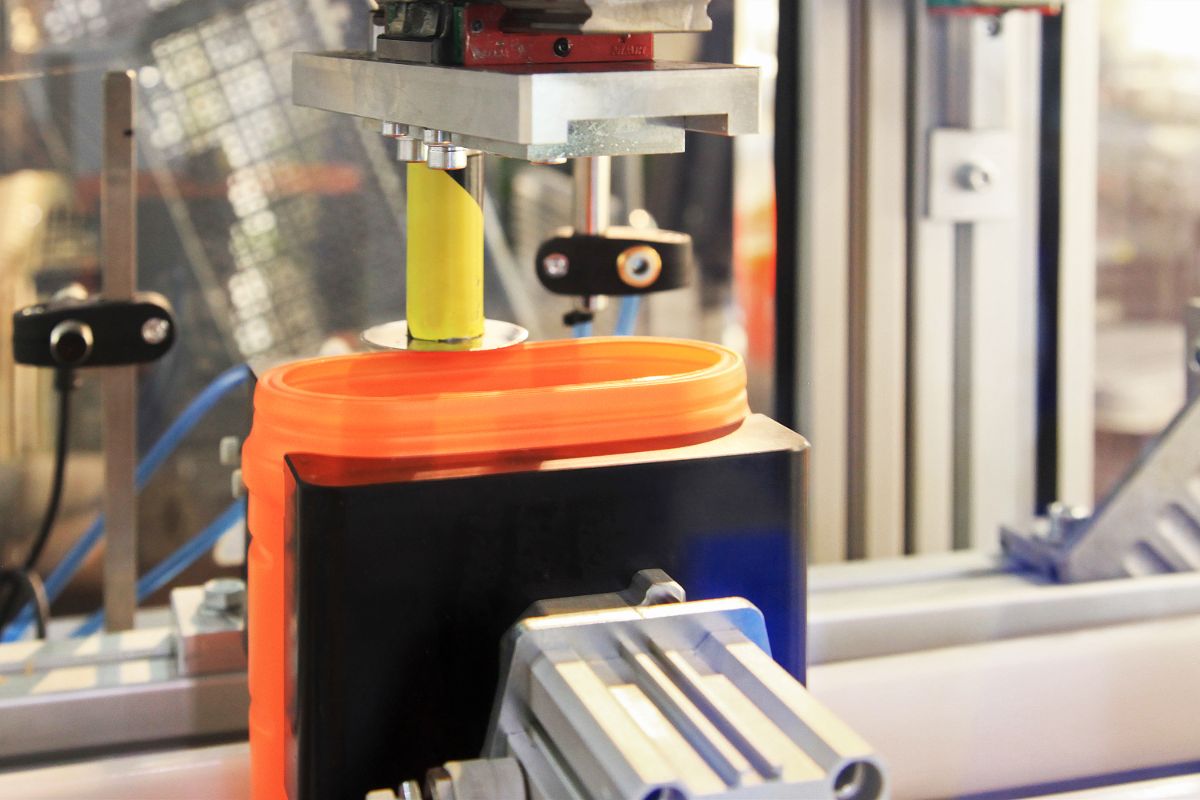

From precision-engineered molds to large-scale production, Chinese plastic mold makers offer a competitive advantage with their advanced technology, skilled workforce, and cost-efficient processes.

In this article, we’ll walk you through the reasons why your businesses might need a plastic mold maker, and how Richfields—one of the leading manufacturers in the industry—can provide the expertise, quality, and scalability you need for your production requirements.

If your business requires high-quality plastic molds at competitive prices, then working with a Chinese plastic mold maker is a practical choice. China has established itself as a global leader in injection molding, offering a combination of affordability, advanced technology, and efficient production.

Whether you need complex mold designs, high-volume manufacturing, or cost-effective solutions, Chinese manufacturers provide the expertise and resources to meet your needs. Here’s how:

China’s lower labor and production costs allow businesses to reduce expenses without compromising quality. As of 2024, the labor costs index in China is 62.10 points, significantly lower than the 121.98 labor costs index in the United States.

This cost advantage, combined with large-scale manufacturing and an efficient supply chain, enables plastic mold makers to offer high-quality molds at a fraction of the cost compared to Western manufacturers.

China’s manufacturing sector has seen significant advancements, largely driven by the “Made in China 2025” (MIC 2025) initiative. One of its key goals is to boost the domestic content of core materials to 70% by 2025, allowing Chinese manufacturers to remain competitive in the global market.

These advancements enable plastic mold makers to produce high-quality, cost-effective molds that meet international standards for precision, durability, and efficiency.

With decades of experience in plastic injection molding, Chinese manufacturers have developed a deep understanding of mold design, production processes, and material selection. Their expertise extends across a wide range of industries, from consumer goods to industrial components, ensuring they can meet diverse production requirements.

Many manufacturers adhere to international quality standards, including ISO certifications, to ensure consistency and reliability. With a strong background in serving global markets, Chinese plastic mold makers are well-equipped to deliver high-quality solutions tailored to specific industry needs.

Whether a business requires small-batch prototypes or high-volume manufacturing, Chinese manufacturers offer flexible solutions that adapt to different production needs. Their large manufacturing facilities, highly skilled workforce, and automated production lines make it easy to adjust output levels based on demand.

With China’s extensive manufacturing infrastructure, companies can increase production capacity without significant delays or added costs. This flexibility ensures that businesses can meet market demand while maintaining cost efficiency and production consistency.

A reliable manufacturer should meet industry standards, use high-grade materials, and deliver products on time. With many options available, businesses must evaluate key factors to make an informed decision. Let’s take a look at some of these:

Quality Standards and Certifications

A reliable plastic mold maker should meet strict industry standards to ensure product safety, durability, and performance. Key certifications to look for include ISO Certification, which guarantees consistent quality management practices, and T516949, which is essential for automotive mold production.

For industries requiring food-safe plastic components, manufacturers with Food and Drug Administration (FDA) Certification and compliance with BPA-Free product standards are crucial. These certifications ensure that the materials used are non-toxic, safe for consumer use, and free from harmful chemicals.

The type of plastic materials and molding techniques a manufacturer uses directly affects product quality and performance. Reliable mold makers should offer a wide range of materials, such as ABS, polycarbonate, polypropylene, and engineering-grade resins, tailored to different industry needs.

Additionally, they should have expertise in various molding processes, including injection molding, over-molding, and multi-cavity molding, to accommodate specific production requirements.

Timely delivery is essential, especially for businesses working on strict production schedules. A mold maker should provide clear timelines for mold fabrication, testing, and shipping to ensure smooth production flow.

Working with an experienced manufacturer that has an efficient supply chain and logistics network can help minimize delays and reduce downtime. Businesses should also consider manufacturers with export experience to ensure hassle-free international shipping.

When looking for a trusted plastic mold maker in China, it’s essential to choose a company with a proven track record of quality, expertise, and reliable service. At Richfields Corporation, we specialize in plastic injection molding and mold fabrication, providing high-quality solutions for businesses worldwide.

With over two decades of experience, we offer cost-effective manufacturing, advanced production capabilities, and strict quality control to meet the demands of various industries. Our facilities in China allow us to produce precision-engineered molds and plastic components while maintaining competitive pricing and efficient lead times.

Whether you need custom mold design, large-scale production, or specialized materials, Richfields delivers expert solutions tailored to your needs.

With China’s strong manufacturing sector and commitment to innovation, companies can benefit from scalable production, strict quality standards, and efficient lead times when partnering with a trusted mold manufacturer.

By choosing to partner with us here at Richfields, you gain access to high-quality plastic injection molding, precision-engineered molds, and cost-effective manufacturing solutions. Our expertise, advanced facilities, and commitment to excellence ensure that your production needs are met with efficiency, reliability, and competitive pricing. Get in touch with us today to discuss your project!