What are the best practices for injection molding tolerance?

- Design with manufacturability in mind

- Select the ideal material for the application

- Factor in tooling considerations

- Apply effective and repeatable process controls

- Utilize a rapid prototyping service

Injection-molded products can be composed of multiple plastic parts assembled in the final stage of manufacturing. This requires proper sizing and alignment — otherwise, the joining of different parts will fail and the product may be unusable.

Determining several manufacturing factors, such as specifications and controls, are needed to achieve the proper sizing and alignment (a.k.a. tolerances). This article briefly explains the best practices for injection molding tolerances, and how to control the quality and usability of your injection molded products.

Why is Tolerance Important in Injection Molding?

Plastic injection molding, while highly accurate, can still create products with slight variations in size and shape. This makes it important for designers and engineers to determine how much is acceptable, and will not impact the function of the parts after assembly. This acceptable variance is called tolerance.

Tolerance is critical, especially for products with multiple parts. In simple terms, optimizing injection molding tolerances is a way of assuming the “in the worst-case scenario.” It determines the acceptable degree that parts can vary in size, shape, and design — without affecting their usability or function.

Design with Manufacturability in Mind

Anticipating possible variances early on is key to avoiding costly redesigns during production. To find adequate tolerances, designers and engineers should follow design for manufacturability (DFM) practices.

These entail designing each injection molded part with the end product and use in mind. By following DFM principles, the manufacturing method and unique restrictions are taken into account. It is then used to determine design features like wall thickness, draft angles, and others.

For example, the desired size of the parts you need requires stricter tolerances. This is because increasing the size of a part can lead to distortions like warping. To reduce this, factoring in size is important.

Another example is wall thickness. This plays a role, especially in the cooling stage. In this, shrinkage occurs, which is partially determined by the wall thickness of the part. Without calculating tolerance, you could end up with a smaller part than intended.

Select the Ideal Material for the Application

The plastic resins you decide on using will play a role in injection molding tolerances. This is because different materials will have varying compositions, chemical properties, weights, and other factors that will affect the possibility of achieving uniform shrinkage.

When picking the materials to be used for your parts, consider these factors:

- Plastic Composition — between amorphous (e.g. ABS) and semi-crystalline plastics (e.g. polyethylene), semi-crystalline plastics have higher shrinkage rates due to their compact structures.

- Molecular Weight: materials with high molecular weights tend to have higher viscosity and higher pressure drops, raising their shrinkage rates.

- Additives — some resins will have fillers to improve or change their physical and chemical properties. However, fillers also influence the shrink rate.

- Usage of Multiple Materials — using more than one kind of resin can cause varying shrinkage rates. This makes adjustments more complicated, and your part is more likely to experience cosmetic defects that affect the tolerance of the parts.

Factor in Tooling Considerations

Another thing to consider is mold design. Upon selecting your materials, injection molders will offer to design custom molds for your application. These take material shrinkage into account by factoring in these tool considerations:

- Tool Cooling — cooling is a crucial step in the production process. The mold design needs to achieve uniform cooling of the molten plastic before ejection to prevent shrinkage, cosmetic, and functional defects. Cooling channels may be placed in the mold to do so.

- Tool Tolerance — molds should be made with highly accurate measurements to maintain accuracy throughout the cycles of heating and cooling. This will ensure that the parts will not experience severe defects, such as wrong sizing, sinking, etc.

- Ejector Pin Location — this pin pushes the final product off the mold, and can come in different shapes. The pressure, shape, and placement of this pin are critical to prevent unwanted dents or scratches on the finished product.

- Gate Location — this is where the molten plastic enters the mold. Location is critical for ensuring the plastic flows to the right place at the right rate and doesn’t result in areas that are too thin or too thick.

Apply Effective and Repeatable Process Controls

Process controls are how injection molders regulate certain variables that could negatively affect part quality. These variables are temperature, pressure, and holding time. Adjusting and monitoring these variables helps reduce their effect on part quality and minimize variance.

One common control method is embedding sensors into the molds to monitor the mold environment — including temperature and pressure — and supplying this information in real-time to production engineers.

Plastic resins generally have higher thermal expansion coefficients — making them more prone to fluctuating in size under sudden temperature changes. Sensors allow engineers and their team to make rapid adjustments if unacceptable variances in temperature and pressure occur. Once they are back under control, the mold will continue to consistently create parts that follow tolerances.

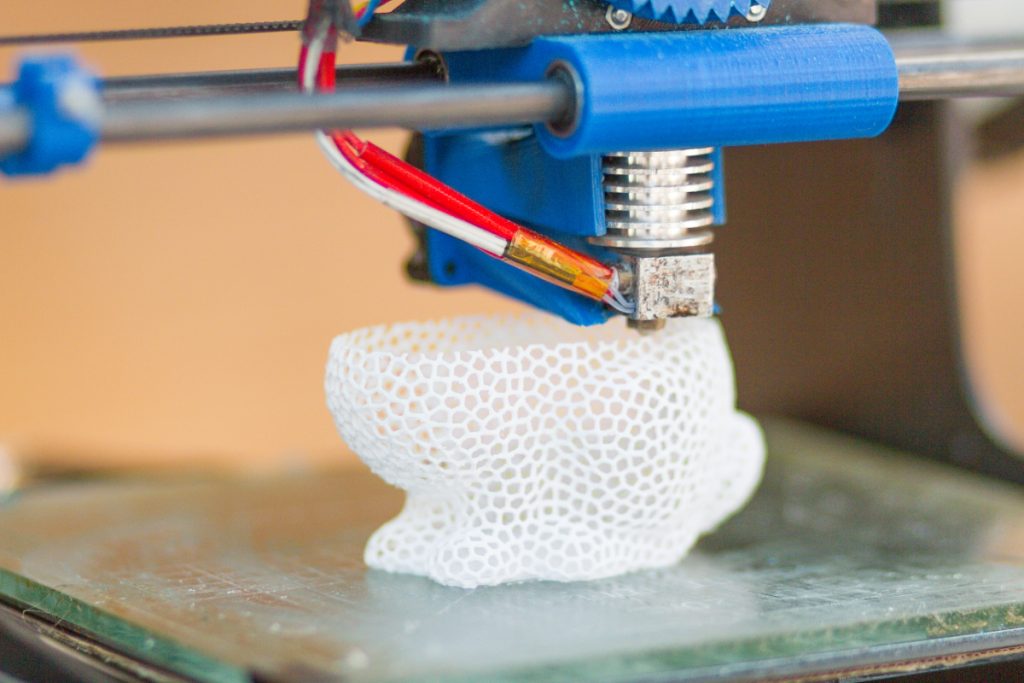

Utilize a Rapid Prototyping Service

Producing high-performing and consistent products from multiple injection-molded requires tolerance optimization. Through skillful design, material selection, and control, it’s possible to make functional and high-quality plastic-injected molded parts.

You can resolve all of these tolerance concerns and optimize your design and process much earlier if you utilize a rapid prototyping service. With Richfield’s prototyping capabilities, you can receive tangible samples of your product in your proposed design. This allows our engineers and designs to give feedback and make early adjustments before production.

Rapid prototyping also allows us to address any manufacturing and design challenges earlier on, and compare several possible designs simultaneously. All in all, it reduces the time, effort, and money you spend on the development stage, and makes your production more efficient.

Key Takeaway

Some degree of variation is inescapable in any kind of manufacturing. Ensuring these variations are kept within acceptable ranges is why tolerance optimization is key to creating high-quality and functional plastic products. To achieve this, follow the best practices for injection molding tolerance needed to create consistent part-to-part quality.

Partnering with an injection molding expert with prototyping services like Richfields is a surefire way to ensure your plastic part designs will meet strict dimensional tolerances. Ready to get started? Contact us today.