August 16, 2022

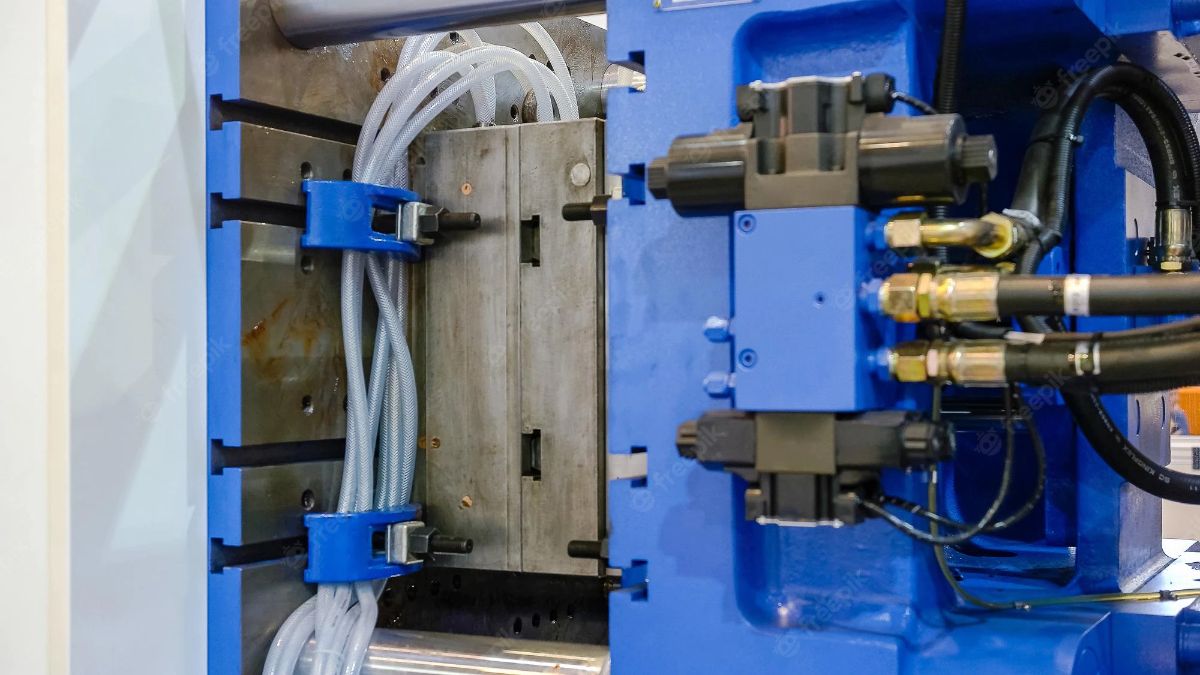

6 Benefits of Plastic Injection Molding for Construction

We can see how excellent each work done by the construction industry is today. From the supermarkets to the houses we live in, the roads we pass through every day, and the high establishments our eyes can see, these things are standing sturdy in the test of time with the help of plastic injection molding in construction. To have cost-effective, reliable products, and solutions in the construction sector, that’s when plastic injection molding enters and helps.

In this post, we discuss the benefits of plastic injection molding for construction. Read on to know if this is the best solution for your next project!

There are three qualities that the construction industry is looking for in plastic products: the ability to withstand weather conditions and chemical exposure, durability, and resilience. Plastic injection molding has all these characteristics and more. Fortunately, plastic products do not rot, unlike metals or woods. Plastics are also lightweight, so it’s easy to secure or transport them in a place. Its lightweight keeps labor costs at a minimum percentage as well as the transportation cost.

And, what are the other specific benefits of plastic injection molding in the construction industry? Find out more below.

Construction clients can place bulk production orders for huge projects or inventory management. They can also collaborate with manufacturers on a fully customized basis, designing one-of-a-kind ingredients to fit into a finely carved gap or an elaborately shaped unit to find a solution. Aside from ordering for bulk productions, you’d get to have a chance for customized ingredients that are fit and successful for your project.

Plastic injection molding components for the construction industry can also be manufactured to any specification. There are no specific limits here. This includes both very small numbers designed to fit into intricate structures and plans and much bigger parts. In other words, the plastic parts can be small enough to fit inside the smallest piece of equipment or large enough to play a critical role in keeping a building or big construction project up straight. This goes to show how flexible plastic products can be.

Numerous construction projects involve some form of insulation or thermal control. Plastic piping and other injection-molded products offer outstanding insulation. And, you can grab this opportunity to make your project better. This is done with no need for any additional materials or additional layers to help keep temperatures at the required level and help stop unplanned heat transference. Plastic injection molded parts have outstanding electrical insulation, reducing unnecessary electricity transference. They are easy to work with and can be formed in concise shapes and sizes to match a larger thermal piping system.

Plastic is a low-cost material that provides the highest quality and durability. That’s why business people mostly benefit from this. When compared to similar construction materials such as glass, metal, or wood, it is typically less expensive and more freely accessible. Once designed, the construction injection molding plates can be used recurrently to produce the same unit without sacrificing quality or efficiency. This makes the method ideal for increased operations, which commonly occur in the construction industry. So, instead of risking your business and budget, here at Richfields, we can offer you high-quality plastic injection molding for your project.

A huge variety of recyclable plastics are accessible for use in the field of construction injection molded products. This helps to reduce landfill and the carbon footprints of construction companies. Plastic’s longevity also means that it does not need to be replaced as regularly as some materials, which means that new parts do not need to be assembled as regularly. That’s why we have tight tolerance when it comes to quality control measures to extremely specialize our plastic parts that need to be molded at a very reasonable price.

Plastic has exceeded many other building materials in terms of looks and adaptability in appearance, color, and theme. Because of how well it can take colors and display wording, images, logos, and more, it is a popular material for signage. Plastic can also look amazing when used in the building of a structure or when used inside for sleek, sparkly, spotless features. Plastic is easier to wash and is difficult to hit or destroy unless done on purpose. That’s why it’s very flexible to use. It is also available in any shade, making it simple to match and blend in with existing infrastructures.

At Richfields, we offer a wide range of OEM plastic injection molding services and can cater to just about any international client. Our plastic injection machines vary in size from 50 tons to 2100 tons, ensuring you high-quality results.

These benefits of plastic injection molding for construction give you more detailed information that you can consider when pursuing a project someday. If you’re interested in our plastic injection molding service, message Richfields now. We also offer other services to help you develop your molds at their best. Reach out to learn more about us, or to discuss your project with us!