August 27, 2025

Benefits of Outsourcing to Plastic Injection Molding in China

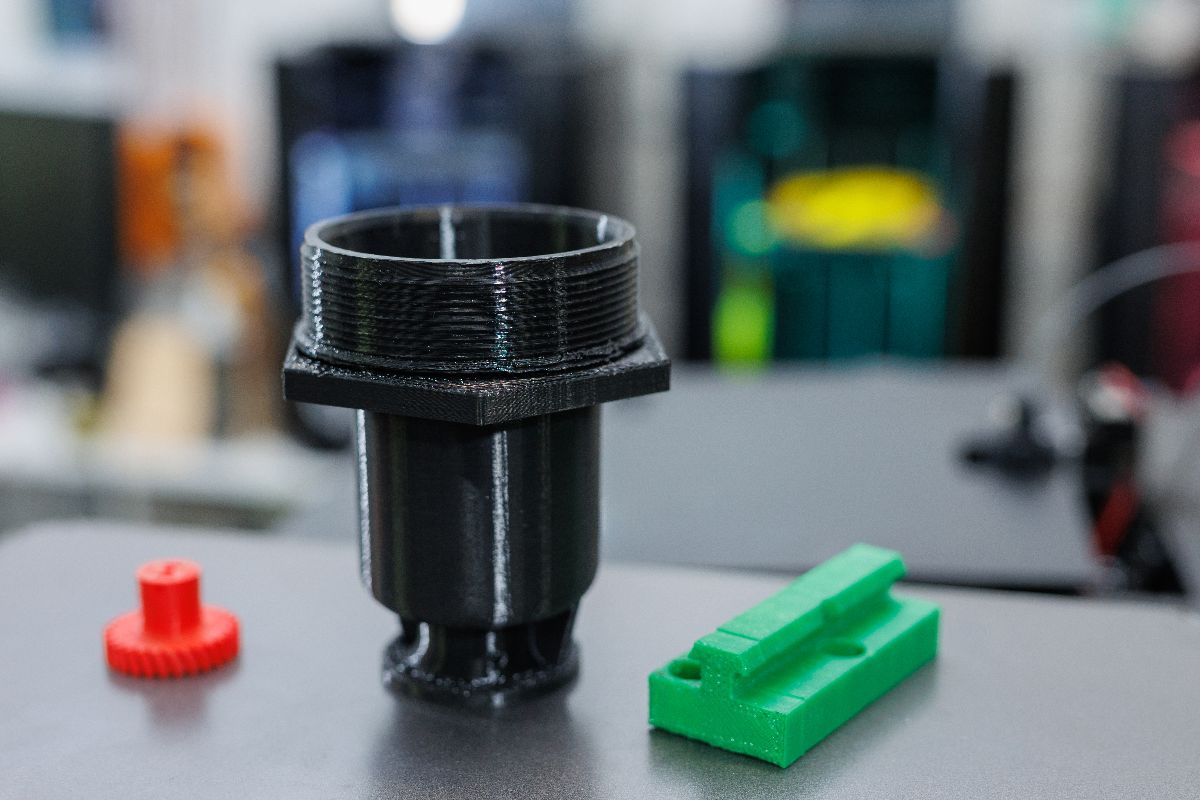

Overview

- Outsourcing plastic injection molding to China allows businesses to significantly reduce production costs while accessing advanced manufacturing capabilities and scalable solutions.

- Companies benefit from quick turnaround times, expert engineering, and flexible customization to stay competitive in demanding markets.

- Richfields stands out as a top-tier partner, offering reliable quality and technical expertise for global manufacturing needs.

Managing production expenses, meeting large-volume needs, and maintaining constant quality are the recurring challenges for companies in today’s competitive market. A lot of businesses, especially those in the US, are exploring intelligent ways to manufacture plastic components without draining resources or compromising regulations.

In this article, we’ll discuss one practical, proven solution that continues to gain attention, including the benefits of outsourcing to plastic injection molding in China. For the past years, this has been a strategic move that resolves scalability, and supply expertise in one package.

With that, if you’re looking for a reputable partner for this, Richfields is a trusted name in plastic injection molding in China. With years of experience and contemporary manufacturing capabilities, we deliver scalable, high-quality solutions that meet the demands of businesses worldwide.

Manufacturing plastic materials internationally enables businesses to cut down significantly on operational costs. With access to minimized labor costs, affordable raw items, and competitive factory rates, companies can make high-quality parts at a fraction of domestic prices.

Many injection molding facilities in China, like Richfields, combine cost-efficiency with dependable output and streamlined production schedules. This setup makes it possible for brands to meet climbing demands without exhausting their budgets or sacrificing quality.

Chinese producers provide companies with access to modern injection molding technologies. From high-tonnage machines to accurate mold-making software, these capabilities allow for effective, top-quality production at scale.

This level of advancement guarantees that even complex, big, or highly detailed plastic parts can be manufactured reliably. As a result, businesses outsourcing to China can confidently meet strict quality standards while keeping their procedures streamlined and competitive.

Handling large, wholesale orders can be a crucial challenge for several companies, especially when demand fluctuates or tight deadlines are involved. Outsourcing to plastic injection molding in China, like the Richfields, makes it more convenient to scale production up or down without compromising precision or product continuity.

These distributors are equipped with high-capacity facilities and a variety of machine sizes, which makes them capable of managing small runs and massive orders. This flexibility helps brands stay responsive to market movements while keeping operational costs under control.

China’s injection molding sector is home to seasoned mold makers and engineers with proven experience in creating various plastic components. Their ability to handle intricate layouts, tight tolerances, and huge molds makes them significant partners for demanding projects.

These experts bring years of practical expertise to every phase of production, from mold fabrication to final checking. With their specialized skills, companies can expect adequate, dependable, and continuously high-quality outcomes in every manufacturing run.

Outsourcing to plastic injection molding in China gives companies a clear benefit when it comes to more immediate turnaround times. A plethora of facilities operate with streamlined workflows, automated systems, and 24/7 production timelines to meet tight deadlines.

This effective setup allows suppliers to manage urgent, high-volume orders without sacrificing quality. As a result, brands can keep up with market trends, seasonal spikes, and product launches with greater ease.

Chinese plastic injection molding providers, like Richfields, are known for delivering flexible solutions aligned with different product requirements. From adjusting material types to catering to difficult geometries and color variations, they can conveniently adapt to diverse project specifications.

This level of personalization allows companies to refine their product designs, respond to market demands, and accommodate niche needs effectively. It ensures that standard and highly specialized parts are produced with consistency and precision.

Now that you know the benefits of outsourcing plastic injection molding in China, it’s also best to understand that they go beyond just cost savings. From accessing modernity and specialized engineers to enjoying scalable production and flexible customization choices, companies gain adequate solutions that help them stay competitive in a demanding market.

Richfields Corporation takes pride in being the leading yet accessible company with reliable plastic injection molding services affiliated with your specific production needs. With us, you can guarantee that everything we deliver is in its optimal condition. So, do not wait any longer. Reach out to us today to learn how we can support your next project with precision, expertise, and efficiency.