June 4, 2025

5 Applications of Large Part Injection Molding

Overview

- Traffic cones and plastic pallets benefit from consistent quality, UV resistance, and custom designs for improved durability and functionality.

- Industrial and automotive parts are molded for strength, lightweight performance, and precise fit, with options for custom features and aesthetic finishes.

- Modern furniture and décor use this process for seamless, stylish, and durable products, including chairs, storage bins, and wall panels.

Whether it’s for transportation, logistics, or industrial use, companies are turning to advanced manufacturing methods to produce large-scale plastic parts efficiently and at scale.

One of the most reliable solutions in this space is large-part injection molding — a process that enables the creation of complex, high-strength components with consistent quality. From traffic cones and plastic pallets to automotive parts and furniture, the applications of large part injection molding span a wide range of industries. Let’s take a look at them.

Traffic cones may seem simple, but they require precise engineering to ensure safety, visibility, and durability under all weather conditions. Large-part injection molding makes it possible to manufacture these cones in high volumes while maintaining consistent shape, color, and performance.

Using UV-resistant and impact-resistant plastics, manufacturers can create traffic cones that withstand prolonged exposure to sunlight, rough handling, and high-speed impacts—essential qualities in both urban and rural road settings.

This method also allows for the integration of reflective elements, weighted bases, and stackable designs, which improve functionality and ease of use. Whether deployed for road construction, event management, or emergency response, cones produced through large-part injection molding offer a reliable and cost-efficient safety solution.

In logistics and warehousing, plastic pallets are essential for the efficient transport and storage of goods. Compared to traditional wooden pallets, plastic alternatives are more hygienic, lightweight, and durable — qualities that make them ideal for industries such as food, pharmaceuticals, and electronics.

With large-part injection molding, it allows manufacturers to create customized pallet designs, including options with reinforced corners, non-slip surfaces, or nestable configurations to save space. They are also resistant to moisture, chemicals, and pests, which helps extend their usable lifespan and reduce operational costs.

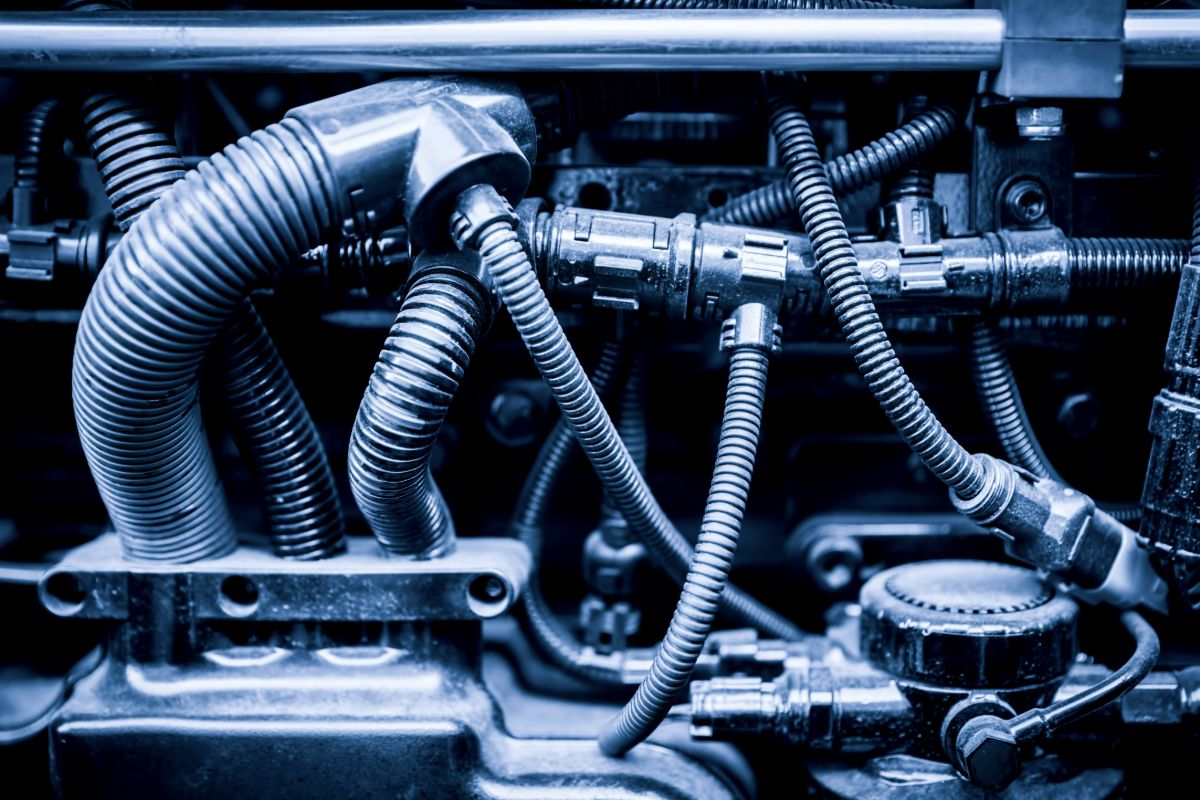

Industrial equipment parts often include machine housings, tanks, enclosures, and custom protective covers that must endure demanding work environments. Injection molding ensures that each part is strong, lightweight, and resistant to wear, corrosion, and extreme temperatures — key factors for industrial performance and safety.

For instance, in agricultural or chemical processing industries, molded plastic tanks and containers are preferred for their non-reactive properties and seamless designs. Similarly, equipment panels and guards made from molded plastic help reduce machine weight while offering the durability needed to protect internal components.

The consistency of the molding process ensures that every part fits precisely, even in complex or large-scale assemblies.

From bumpers and dashboards to door panels and under-the-hood components, the process of large-part injection molding allows automakers to create lightweight parts without compromising on strength or design accuracy. This is especially important as the industry shifts toward electric vehicles (EVs), where weight reduction plays a crucial role in improving energy efficiency and performance.

This process’s flexibility also supports aesthetic customizations such as texture, color matching, and integrated fastening systems. This means manufacturers can meet both performance and design goals in a single, streamlined process. It’s also much easier to mass-produce components with complex geometries while ensuring each piece meets strict automotive standards for safety and reliability.

Large-part injection molding has also become a key process in the production of modern furniture and decorative items. Its ability to shape complex designs with precision allows manufacturers to create functional yet visually appealing pieces quickly and consistently.

This method is especially useful for producing items that require seamless finishes, lightweight structure, and durability — qualities that are important for everyday use in both residential and commercial spaces.

Here are some examples of furniture and decorations often made with large-part injection molding:

This technique offers a winning combination of design flexibility, production speed, and durability, making it a go-to solution in the world of contemporary furniture and interior decor.

From traffic cones to industrial equipment and modern furniture, the applications of large part injection molding continue to grow across industries. Its ability to produce strong, detailed, and cost-effective components at scale makes it an ideal solution for manufacturers looking to balance performance with efficiency.

At Richfields Corporation, we specialize in large-part plastic injection molding that meets global standards for quality and precision. Ready to bring your next big product to life? Contact us today to learn how our manufacturing expertise can support your goals.