How can PVC plastic tiles be made using large plastic injection molding?

- Molding large tile formats

- Imprinting detailed surface textures

- Blending PVC with additives

- Producing multiple tiles simultaneously

- Integrating interlocked design features

Overview

- Enable large-format tile molding with uniform thickness and dimensional stability.

- Imprint detailed surface textures directly from the mold for function and aesthetics.

- Blend PVC with additives for enhanced durability, flexibility, and safety.

- Produce multiple interlocking tiles efficiently with consistent quality in each batch.

PVC plastic tiles are widely used in both residential and commercial spaces thanks to their durability, low maintenance, and design versatility. Producing these tiles on a large scale requires an efficient and consistent manufacturing method—this is where PVC plastic tiles from large plastic injection molding come in.

This process enables manufacturers to create high-volume, high-precision tile designs that meet modern standards for strength, texture, and interlocking functionality. In this article, we’ll explore how this method supports the production of PVC tiles and why it’s a preferred option in large-scale manufacturing.

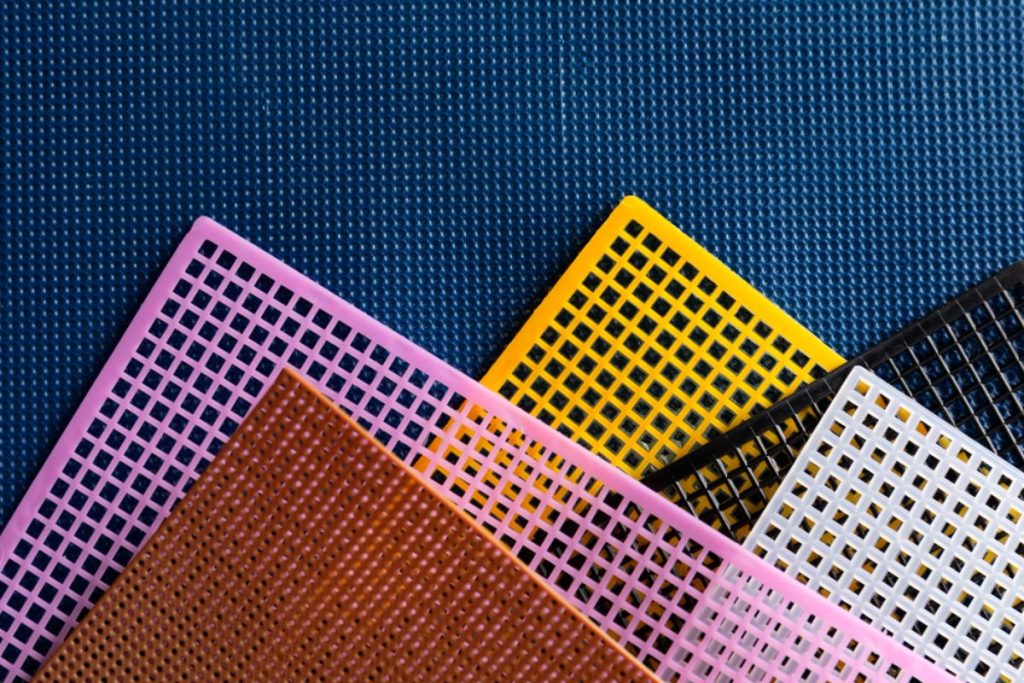

Molding Large Tile Formats

Producing PVC plastic tiles in large sizes requires a molding method that can maintain consistent quality across each unit. Large plastic injection molding is well-suited for this because it applies even pressure and temperature control across the mold, ensuring that every corner and edge of the tile forms accurately.

With large-format tiles, warping or inconsistencies can lead to installation issues and structural instability. The injection molding process helps eliminate those risks by delivering uniform wall thickness, reducing air pockets, and improving dimensional stability. As a result, tiles come out of the mold with clean lines and true-to-design specifications—ideal for commercial and industrial applications.

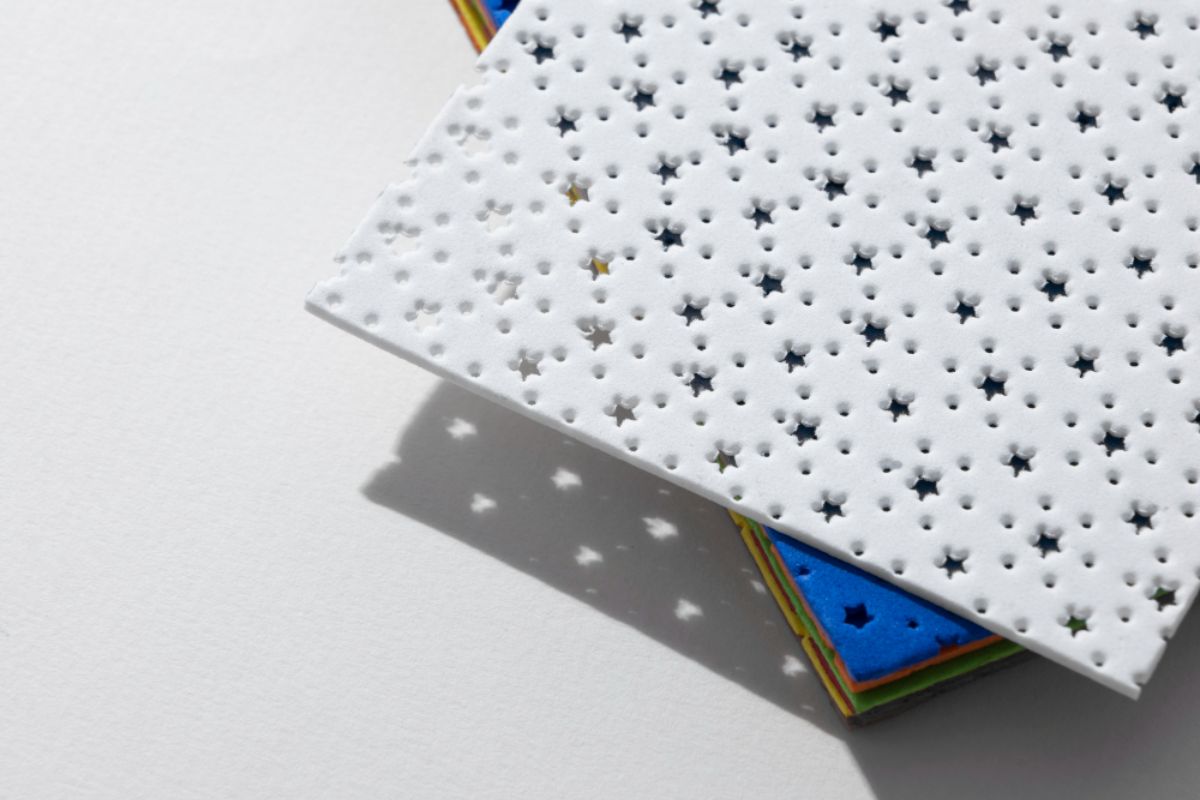

Imprinting Detailed Surface Textures

Molds can be designed with detailed patterns—wood grains, stone finishes, or geometric designs—that are imprinted directly onto each tile during the injection process. This eliminates the need for post-processing and helps maintain production efficiency.

Textured finishes aren’t just for aesthetic appeal. They also add practical benefits, such as slip resistance for safety, or the ability to hide minor scuffs and scratches. For applications in high-traffic environments, like public buildings or retail stores, these design features make the tiles more functional and long-lasting.

Blending PVC With Additives

PVC is a versatile plastic, and by mixing it with specific additives before molding, manufacturers can enhance key performance traits. These additives might include UV stabilizers for outdoor tiles, flame retardants for safer indoor use, or plasticizers to increase flexibility without compromising strength.

During the injection molding process, the PVC compound is melted and injected into the mold under controlled conditions. Because the material mix is consistent, the properties of the finished tile—like color, durability, and resistance to heat or chemicals—are also uniform.

Using large plastic injection molding also allows for better dispersion of additives throughout the entire tile body. This ensures that enhancements are not just surface-deep but integrated into the structure of the tile. The result is a stronger, longer-lasting product that performs reliably in its intended environment.

Producing Multiple Tiles Simultaneously

One of the main benefits of using large plastic injection molding is its capacity for high-volume production. With multi-cavity molds, manufacturers can produce several PVC plastic tiles in one cycle. This dramatically reduces the time and cost per unit while maintaining consistent quality across all pieces.

Multi-tile molding is especially valuable when producing standardized tiles for large installations, such as commercial flooring or institutional buildings. It ensures uniformity in size, color, and finish across hundreds or even thousands of tiles—something that’s difficult to manage with manual or semi-automated production methods.

Integrating Interlocked Design Features

Interlocking designs are essential for PVC plastic tiles that need to be easily installed, removed, or replaced. With large plastic injection molding, these features—like tongue-and-groove edges, click-lock systems, or snap-fit joints—can be molded directly into each tile.

The precision it offers ensures that interlocking elements are produced with tight tolerances, which is critical for tiles to align correctly and remain securely in place during use. This is particularly useful for modular flooring systems or temporary setups where speed and ease of installation are important factors.

Combined with the inherent strength of molded PVC, these design features result in a tile system that is durable, easy to maintain, and simple to upgrade when needed.

Key Takeaway

PVC plastic tiles from large plastic injection molding offer a reliable, scalable solution for industries that demand high-quality, durable, and precision-made components. Whether it’s replicating detailed textures, incorporating interlocking systems, or producing multiple units at once, this manufacturing process supports both design flexibility and consistent performance.

At Richfields Corporation, we specialize in large-part plastic injection molding that meets global standards for quality and efficiency. If you’re looking to bring your PVC tile concept to life, no matter the size or complexity, our team is ready to help. Contact us today to learn how our capabilities can support your next production run.