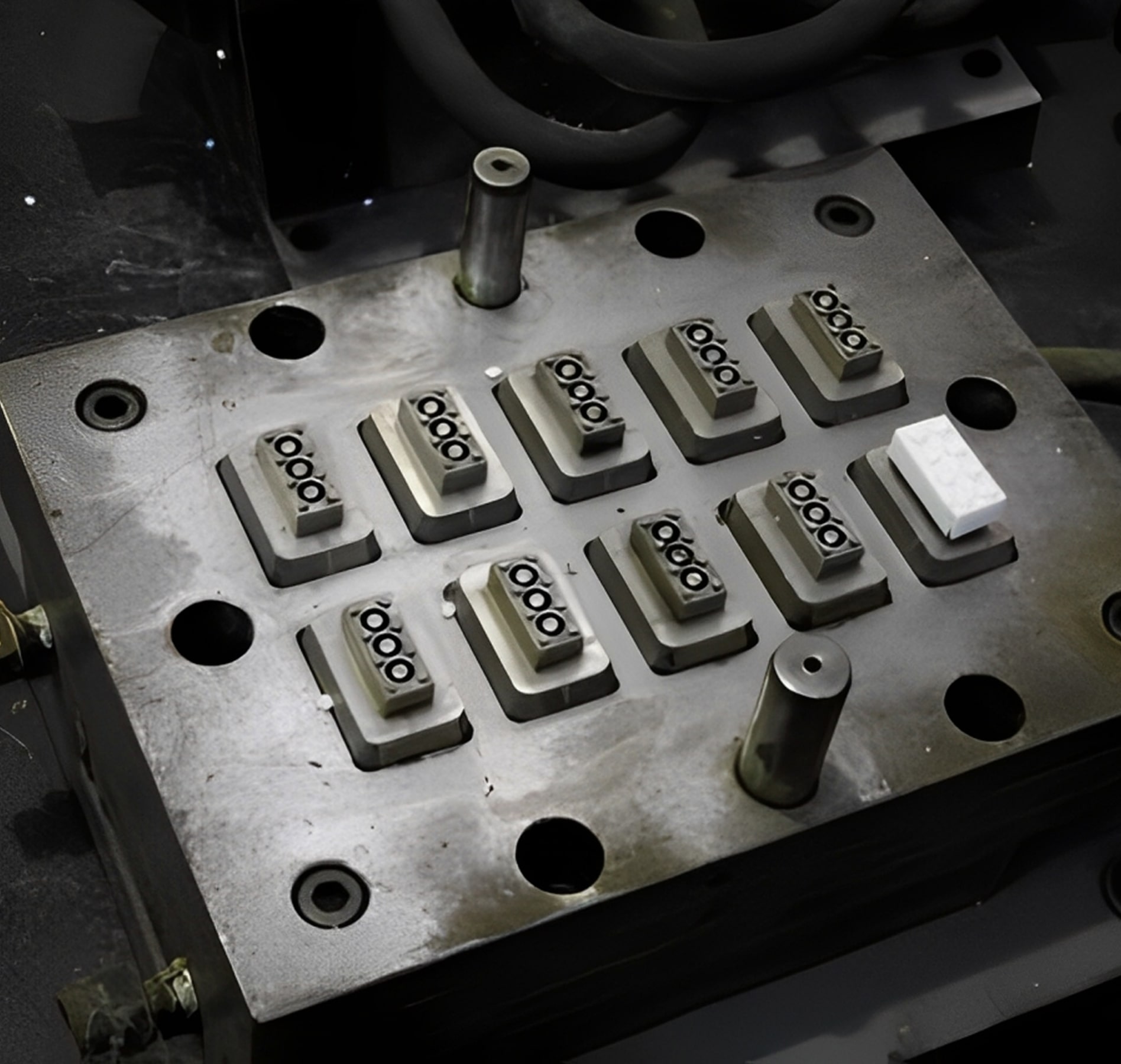

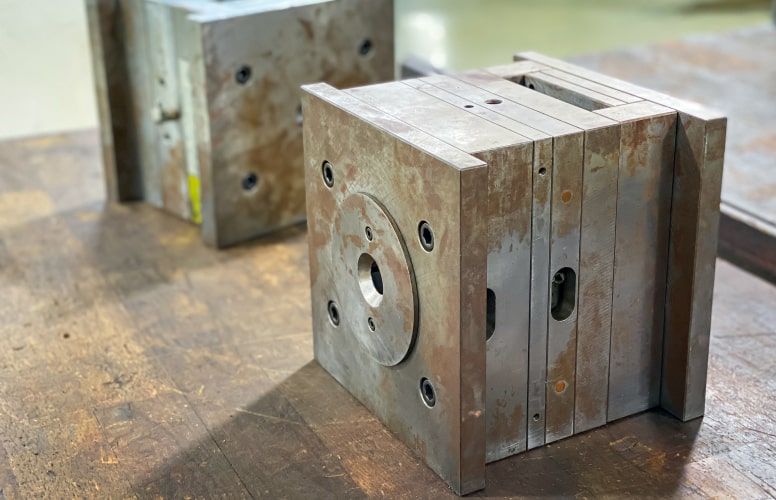

Rubber Injection Molding China

Richfields has rich experience in working with customers who require rubber injection molds for rubber products. Specifically, we have worked with materials such as TPE (Thermoplastic Elastomers) and TPV (Thermoplastic Vulcanizates), which offer the flexibility of rubber with the processing efficiency of thermoplastics. Our expertise allows us to design and manufacture high-precision molds tailored to the specific performance requirements of each application. Whether it’s for consumer goods, FDA-grade products for food and medical use, or durable components for industrial machinery, we ensure that every rubber part we produce meets strict quality and compliance standards.