May 27, 2024

What is an Unscrewing Mold?

Overview

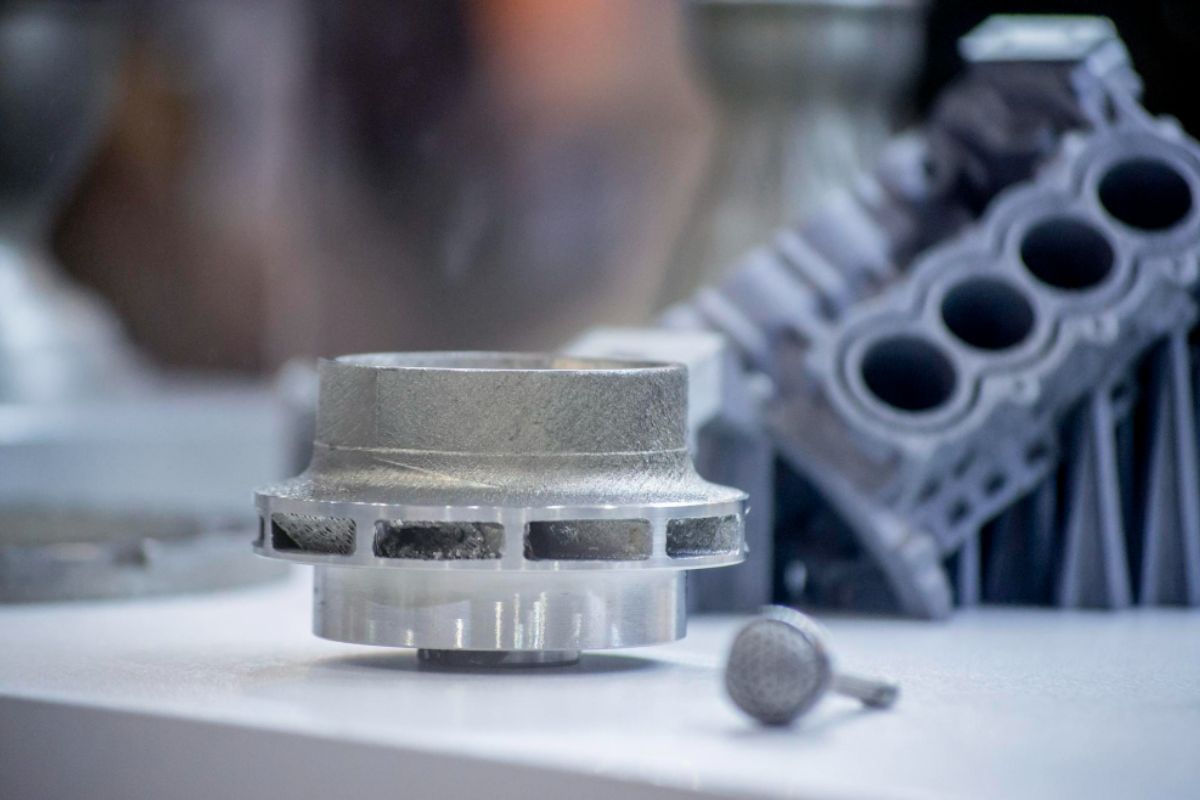

- Unscrewing molds are specialized types of plastic injection molds. It is used for producing threaded components, offering efficiency, precision, and versatility.

- They are used across various industries, including medicine, manufacturing, automotive, and consumer goods.

- These are for items such as sprinkler heads, bottle caps, and medical supplies.

- The unscrewing mold process involves the use of threaded plastic materials. Two examples are polypropylene and high-density polyethylene.

- There are different types of unscrewing molds: hydraulic, servo-driven, and mechanical. Each has its own advantage.

- The unscrewing molding process is simple. It reduces the need for additional manufacturing operations and labor costs.

Efficiency, precision, and versatility are important factors in plastic injection molding. With different molding types contributing to the innovation of the production, unscrewing mold stands out in many ways. It is a specialized type of mold where many of our common items are from. It is the method used for many products in medicine, manufacturing, and more.

In this article, we dive into its intricacies, exploring what exactly is an unscrewing mold. This technique is trusted by many reputable manufacturers, and, today, we seek to learn why. However before we learn its key benefits, we first should know its definition.

An unscrewing mold is a unique variety of injection molding. It includes movement and rotation to produce components. The main material of this molding process is threads. These are made out of polypropylene and high-density polyethylene. They come in different types and using them depends on the purpose of your product. They are molded together in an intricate pattern to create each distinct product design. After that, they are gently unscrewed from the molding.

Some of the components that are produced with this technique are the following:

To make these products, a few pieces of equipment are also needed. These include racks, motors or hydraulic cylinders, and gear racks. As mentioned, unscrewing mold is the key to making a successful production of your item.

Here are a few types you can choose from:

Using the best plastic thread material and the right molding can help ensure the quality of your product.

With the many types of plastic manufacturing available today, it may become overwhelming to choose which process is right for you. Each method offers its own set of advantages and considerations. Unscrewing mold is the same. It offers an array of benefits that impact the overall quality of your production and item.

If you have an intricate or detailed design, this process is the best technique for the creation of your product. The equipment and machinery used allow for a more detailed style. With accurate threads or undercuts, it is possible to shape the plastic to your desired outcome since they may not be produced by conventional methods.

With unscrewing mold, it will be made without further hassle. That’s why it is ideal for the automotive and medical industry where every component needs high precision and accuracy.

The unscrewing molding process is a simple operation. Since it is a straightforward technique, it eliminates the need for additional operations. This means a reduced assembly time or post-molding assembly. Its shortened production makes it ideal for high-volume demands.

With precision in the core of its basic operation, it does not compromise the quality of every component made. This makes it a trusted method for any in-demand plastic product. Its uncomplicated method also results in reducing labor costs. Furthermore, the combination of simple operation and low labor costs results in a cost-effective production.

Since the main quality of the unscrewing mold is its precision, its method is often the foundation of many versatile patterns. It can generate parts of many sizes and forms, without making it complicated to change the unique specifications of the product. Changing its design is a simple process.

This is often why many industries use unscrewing molds—from electrical to consumer goods, it is a reliable process to meet their product’s blueprint.

The unscrewing mold method is important in the field of plastic injection molding. It is an advanced method that offers manufacturers versatility. Their ability to accommodate a range of industries makes them one of the best processes. With flexible applications, unscrewing molds meet the many demands in the market.

Looking for plastic mold manufacturers? Richfields Corporation is your reliable China-based partner in the industry of plastic injection molding. Serving a variety of industries from medicine to automotive, we are dedicated to giving you your perfect product. Not only that, our decade’s worth of experience will guide you on the overall quality of your material. Trusted by many US businesses, our satisfied clients are a testament to our services. Contact us today for more inquiries.