August 19, 2019

Different Types and Applications of Hot Runners

Plastic injection molding technology has constantly evolved over the years, with various companies adding new tweaks and functions that help improve manufacturing quality and efficiency. One of the innovations that have helped revolutionize plastic injection molding was the development of hot runners.

Utilized by mold manufacturers in China, the United States, and countries in Europe, this system has been able to create a manufacturing process that has drastically improved overall production quality while shortening manufacturing time. Let us know more about what hot runners are, how they work, and the advantages they have brought to the plastic injection molding industry.

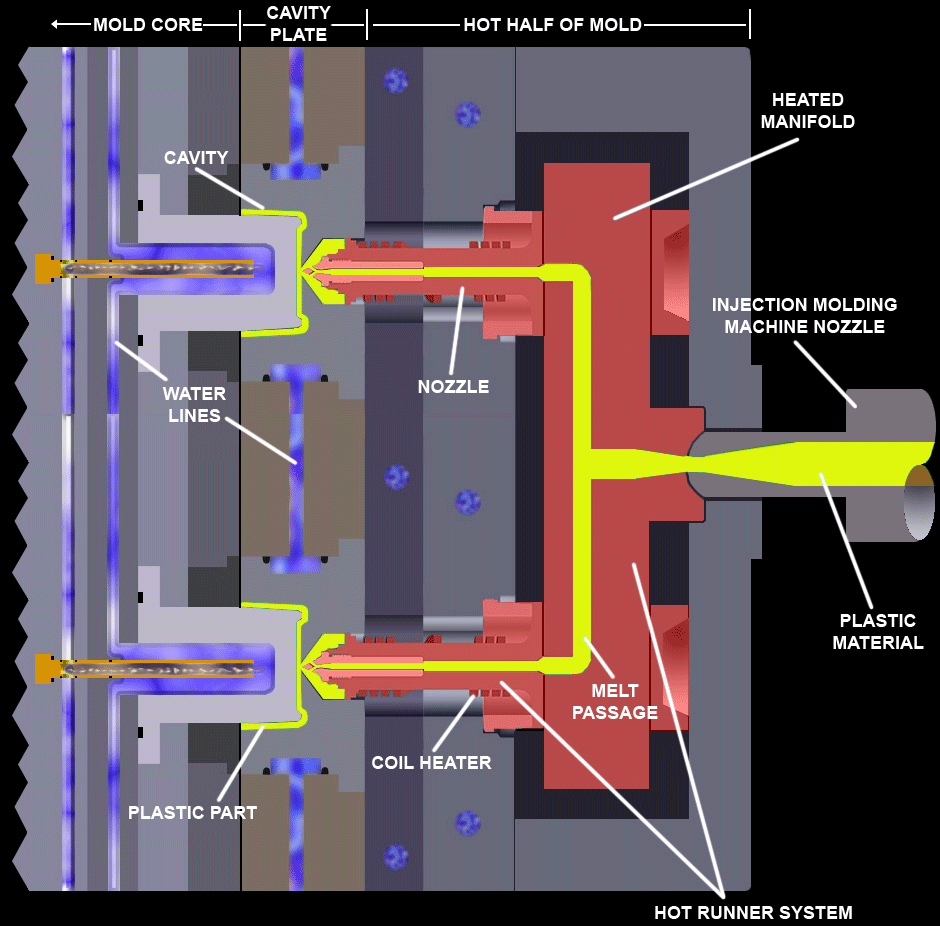

A hot runner is a plastic conveyor system that is used to inject molten plastic into molds. It features a series of nozzles that are able to disperse various amounts of plastic to a series of molds and can range from 1 to a maximum of almost 200 depending on the size of the mold. Hot runners are designed to constantly inject molten plastic into molds for better production efficiency.

Hot runners work through the use of a temperature controller that heats the whole runner system, allowing the runners to deliver molten plastic to mold cavities. These temperatures can be adjusted accordingly to ensure the best part quality, and make sure that only molten plastic is going through the molds.

Compared to cold runners, hot runners are able to maintain the same consistency of molten plastic, which ensures that there would be fewer defects present in each mold, lessening the amount of plastic scrap accumulated during production.

A hot runner consists of the following parts:

Inlet – This is the part in which resin enters the injection nozzle during the molding process.

Manifold – This part allows the molten resin to enter the heated nozzles to be injected into the mold cavity.

Locating Ring – This is a ring that is adjusted according to the placement of the injection mold and aligns all nozzles together.

Heater Technology – This refers to the hot runner system as a whole. Each hot runner has specific heating and temperature control systems that cater to different plastic manufacturing methods, and ensure the best cost and performance.

Valve Gate Hot Runner – This type of hot runner adds a valve into the system, which stores the molten plastic that would then be released in the valve gate. This is a more precise and accurate system that provides better product quality and increased manufacturing efficiency.

Hot Sprue Molds – This type utilizes a hot sprue where plastic is fed and molten during the production process. This type works best for single-cavity molds and can produce multiple products at the same time if need be.

Hot runners have a wide set of advantages compared to cold runners, making them the best fit for mass-producing plastic products. Here are some of their advantages:

Save more materials – The more efficient process of using hot runners ensures that you would be able to save more plastic materials, reducing the amount of waste produced overall. Plastic waste is one of the biggest concerns present in the industry, and hot runners enable manufacturers to lessen waste and even reuse more plastic.

Improved quality – The increased precision provided by hot runners helps improve overall product quality, which means that the chance of producing defective products will significantly go down, allowing for a more cost-effective manufacturing process overall.

Hot runners have set a high standard in the plastic injection molding industry. Providing a more accurate and efficient process, this system allows companies to create high-quality products, and mass-produce them at a much faster rate.