What are the advantages of precision molding made by a company in China?

- Speedy production

- Punctuality

- Volume production

- Design precision

- Production of multiple styles

The industry around plastic injection molding is innovating as it goes along. In China, a molding company can sense these changes as long as production is concerned and the development with the emergence of new trends in the manufacture of goods reveals an impressive feat in precision molding. The molding of plastic has since grown efficient and has a massive turnaround every chance it gets. If you would be interested in a partnership with a molding company in China, you should consider a couple of important factors so you can figure out what you want to achieve for your business.

Speedy Production

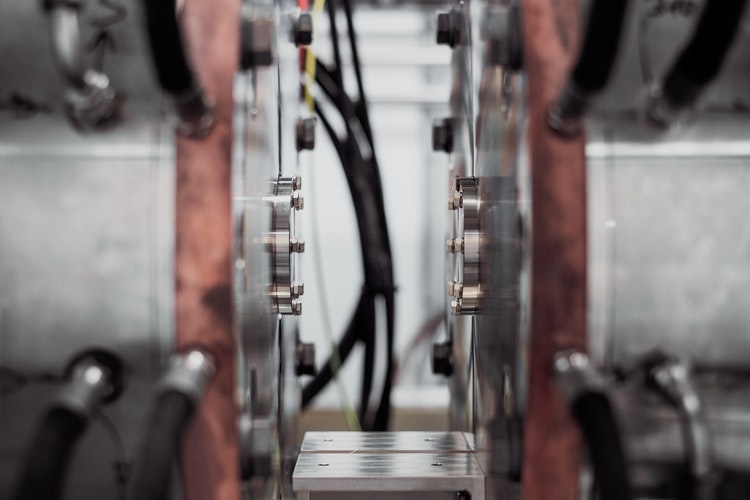

The plastic injection molding industry allows for the production of parts in fewer steps and with a tighter control of materials and waste products. The clamping and injection materials in precision molding will bring about higher results in the quality of your desired products. Essentially, this allows you to produce a very large number of products quickly at a high quality, with production cycle times as low as 15 seconds.

Punctuality

One of the best advantages of employing precision molding from a molding company is the rapid services that can be fired at your convenience. Taking the demands of the fairly competitive industrial sector, punctuality will go a long way in achieving the requirements that you will need for your business.

It is important that you know about this advantage of precision molding from an injection mold maker in China so that you can maximize it at its full extent. By knowing this, you can adjust timetables and costs in accordance with the capability of the injection mold suppliers; precision molding will surely put these things in favor for you to ensure an accurate production of goods.

Volume Production

The cost advantages of precision molding are astounding and they become more pronounced for large-volume production runs.

As precision and accuracy improve, the process from a Chinese molding company also becomes a cost-efficient option that depends on how many units you need and the specifics of your product design. With the current technology, the major advantage of precision molding all boils down to automation efficiency.

A mold manufacturer in China, which uses a highly-automated procedure that employs machinery and robots that can be controlled by a single operator, will produce products of the highest quality. Not to mention that this can also significantly reduce both labor costs and manufacturing costs, which will definitely generate savings for your business.

Design Precision

The automated nature of the plastic injection process enables great design precision and accurate loyalty to the concept. Plastic molding uses computer-aided design and computer-aided manufacturing, which will greatly allow highly precise specifications. This advantage provides extremely close monitoring for better quality control. This means that the precision of plastic injection molding will provide excellent design and flexibility. The combination of digital design with the precision tolerance will provide engineers with a great deal of structural freedom.

The design flexibility of precision molding is unmatched because the very process enables solid design strength. The plastic molding process allows for fillers to be used in injection molds which can reduce the density of plastic during molding and add strength to the parts long after molding is completed. This makes plastic injection molding well-suited to industries where high product strength is a great requirement.

Multiple Styles

Precision molding from a mold manufacturer in China provides a wide allowance to ensure that the production is faithful to the design. It is also easy to use the same mold with different materials or product colors. This also brings co-injection molding into play since it enables different types of plastic to be used simultaneously. High pressure used during the whole plastic injection process also supports intricate detailing of parts. Sometimes the same part needs to be in different colors based on your own product lines or customer branding and with precision molding ensures that these requirements can be met.

The injection molding process allows complex and intricate shapes to be manufactured. The shapes that would be too difficult or costly to manufacture with the different processes needed would be easier for the plastic injection molding to fully maximize its advantages. These advantages include quickly shifting colors and even materials that are used for the parts you want to manufacture with different processes. It also allows for a high volume of plastic parts to be manufactured at the same time with the same mold and quality.

Key Takeaway

Based on the advantages listed above, the high precision molding process will assist you with your production related works. In addition, you should also take requirements you have for your project in serious consideration. This is important in order to maximize mold services to its full extent and to excel in the manufacturing of your products.