December 5, 2024

From Concept to Market: The Role of Chinese Plastic Overmolding in Accelerating US Product Development

Overview

- For U.S. companies aiming to bring innovative products to market quickly, overmolding has become the main manufacturing solution.

- Chinese manufacturers, known for their advanced technologies such as 3D printing and CAD, provide cost-effective and efficient solutions that help U.S. businesses reduce production time and costs.

- Partnering with Richfields can accelerate product development, reduce costs, and help you stay ahead in a competitive market.

Bringing innovative products to market requires speed, efficiency, and precision. Plastic overmolding, a process that combines multiple materials into a single product has become a central part of modern manufacturing. This technique enhances product durability and functionality and allows businesses to meet the growing demand for high-quality designs. Many U.S. businesses turn to plastic overmolding services overseas as part of their development strategy.

Chinese manufacturers have become leaders in providing these services, offering cost-effective, high-quality solutions tailored to global standards. This collaboration allows them to focus on innovation without compromising on quality or timelines.

Precision and reliability are essential for overmolding solutions, particularly in industries that demand high-performance components. At Richfields Corporation, we excel in crafting intricate, high-quality components tailored to the specific requirements of sectors like automotive and medical devices. Our comprehensive services, from mold design to production, ensure each project aligns with our clients’ unique needs and industry standards.

Backed by over 20 years of experience and ISO 9001-certified processes, we consistently deliver dependable solutions that adhere to global quality benchmarks. Leveraging advanced technology, our team ensures fast turnaround times, enabling businesses to accelerate their time-to-market and maintain a competitive edge.

Through competitive pricing and a customer-focused partnership approach, we blend cost efficiency with an unwavering commitment to quality.

With their expertise in advanced manufacturing techniques and efficient production processes, Chinese Manufacturers provide cost-effective solutions without compromising on quality. By tapping into their capabilities, companies can enhance their competitiveness, improve production timelines, and access specialized knowledge to bring products to market faster.

Labor costs in China are significantly lower, with rates averaging around $3.70 per hour compared to U.S. rates that can exceed $30 per hour, leading to considerable savings in production.

Their vast supplier network also offers high-quality materials at competitive rates, helping to further reduce production costs. This enables them to produce at lower material costs, allowing U.S. companies to scale operations more affordably while maintaining product quality.

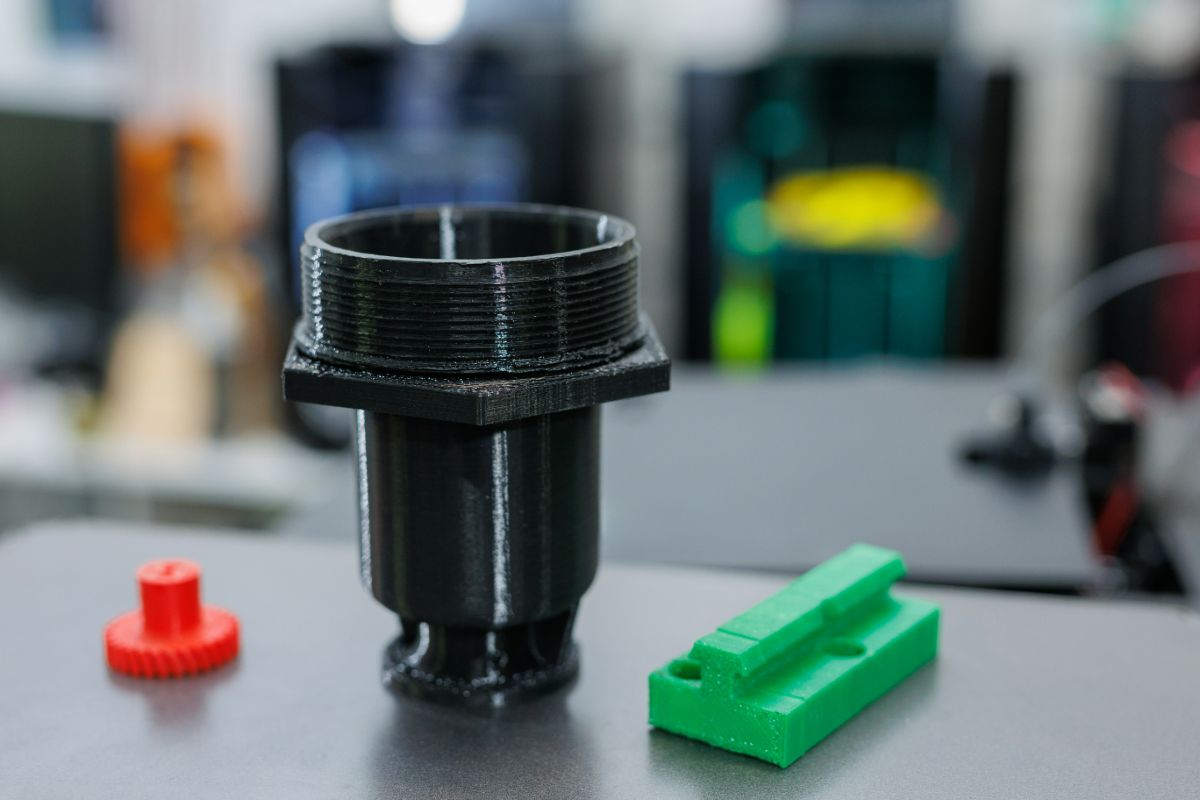

3D printing and Computer-Aided Design (CAD) have transformed overmolding by providing faster and more cost-effective prototyping. These tools allow for the creation of complex parts directly from digital files, eliminating the need for traditional tooling and speeding up the design process.

With CAD, designers can quickly make changes and test different material combinations, streamlining the product development cycle. Rapid prototyping through 3D printing reduces time-to-market and helps businesses lower production costs while improving the final product’s quality through real-world testing and refinement.

Skilled engineers and technicians in China bring advanced knowledge in precision engineering, allowing them to manage complex projects with high-quality standards. These professionals also benefit from continuous training, ensuring they stay current with the latest manufacturing techniques and technologies.

This expertise is paired with cutting-edge manufacturing techniques, such as CAD, CAM, and automation, which enhance production precision and efficiency, making Chinese manufacturers a cost-effective solution for U.S. companies without the need for extensive in-house R&D investments.

Chinese manufacturers have improved in quality control and innovation, making them reliable partners for U.S. companies needing high product standards and fast development. With advanced machinery and automation, they reduce errors and maintain consistent quality.

They follow a strict quality control process, including inspections at every stage and third-party audits to meet requirements. Their focus on continuous improvement and collaboration with clients helps them stay competitive, adapt quickly, and deliver innovative products that meet global standards.

Overmolding suppliers in China are known for their ability to adapt to varying production needs, making them ideal partners for U.S. companies. They offer rapid prototyping services that allow businesses to test new products with small batches before committing to mass production, minimizing risk.

When demand increases, these suppliers can scale up efficiency to produce high volumes, benefiting from economies of scale to reduce unit costs. This flexibility in production, combined with the ability to customize processes, allows U.S. businesses to respond quickly to market shifts and maintain competitive advantage.

Outsourcing the overmolding process helped U.S. firms focus on design and marketing while taking advantage of the efficient production capabilities of their Chinese partners.

Richfields Corporation used advanced techniques like 3D printing and high-speed injection molding to quickly produce and refine prototypes, reducing the time it takes to launch new products.

Our streamlined production process also shortens lead times, allowing U.S. companies to ramp up to full production quickly. The cost savings from outsourcing gives them a chance to invest more in research and development, leading to even more innovation.

Plastic overmolding services offer U.S. companies a powerful way to speed up product development and improve market readiness. As a reliable manufacturing partner, Richfields Corporation helps clients navigate the entire product development cycle—from concept to mass production—providing high-quality results at every stage. Connect with our team today for more information.