What are some plastic molding services in China?

- Precision plastic injection molding

- Plastic over-molding

- Large-part injection molding

- Injection molding

- Plastic mold maker

Overview

- Plastic injection molding services in China offer precision, efficiency, and affordability across industries like automotive, electronics, and logistics.

- Businesses can benefit from advanced techniques such as precision molding, over-molding, and large-part injection molding.

- Skilled plastic mold makers ensure durable, high-performance components by selecting the right materials and refining production techniques.

China has become a global leader in plastic manufacturing, offering businesses cost-effective solutions without compromising quality. For companies looking to produce high-quality plastic components, choosing the right plastic injection molding services in China is essential for ensuring precision, efficiency, and affordability.

From precision injection molding to large-part production, let’s take a look at how businesses in the U.S. can benefit from a wide range of services tailored to different industries — helping companies make informed decisions to optimize costs and achieve high-performance results.

Precision Plastic Injection Molding

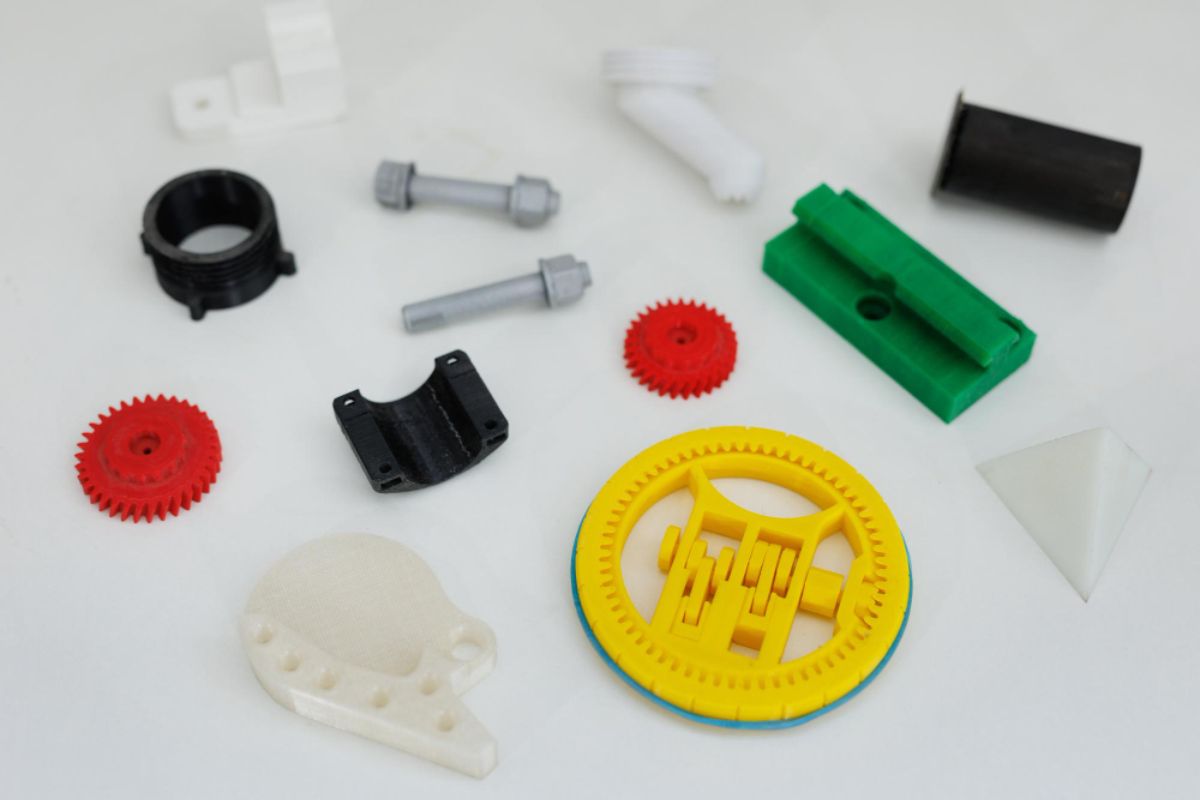

As manufacturing technology advances, the demand for high-precision plastic components continues to grow. Precision plastic injection molding is designed to meet these evolving requirements, offering exceptional accuracy for even the most intricate designs.

Unlike conventional injection molding, precision molding utilizes specialized molds and high-tolerance engineering to achieve detailed features with minimal deviation. By using advanced equipment and refined production techniques, manufacturers can produce plastic components that rival the precision of metal parts while maintaining cost efficiency.

Plastic Over-Molding

Plastic over-molding involves molding multiple materials together to create a single, seamless component. This process is widely used across various industries, from consumer goods to automotive and medical applications.

The success of plastic over-molding also depends on the compatibility of the materials used. Selecting the right materials ensures a strong bond and enhances the product’s overall performance. Some commonly used materials in over-molding include:

- Polyetherimide (PEI) – High heat resistance and mechanical strength.

- Acrylonitrile Butadiene Styrene (ABS) – Excellent impact resistance and toughness.

- Polyetheretherketone (PEEK) – High-performance thermoplastic with superior chemical resistance.

- Polymethyl Methacrylate (PMMA) – Transparent and highly durable.

- High-Density Polyethylene (HDPE) – Strong, lightweight, and moisture-resistant.

- Low-Density Polyethylene (LDPE) – Flexible and impact-resistant.

- Polypropylene (PP) – Durable and chemical-resistant.

- Thermoplastic Elastomers (TPE) – Rubber-like flexibility for improved grip.

- Polyoxymethylene (POM) – High stiffness and dimensional stability.

Large-Part Injection Molding

Its flexibility and precision make large-part injection molding an essential technique for producing high-quality plastic components across various industries. Its ability to create large, durable, and lightweight parts ensures its continued demand in global markets. It also has a wide range of applications — here are some of them:

Automotive Parts

This process is integral to producing critical vehicle components like fenders, hoods, grilles, paneling, and door covers. These parts contribute to weight reduction, fuel efficiency, and overall durability, making them a top choice for leading automotive brands.

Sports Equipment

Many sports manufacturers rely on large-format plastic molding to create durable and high-performance gear. This method is particularly beneficial for water sports equipment, including kayaks, canoes, surfboards, and rowing shells.

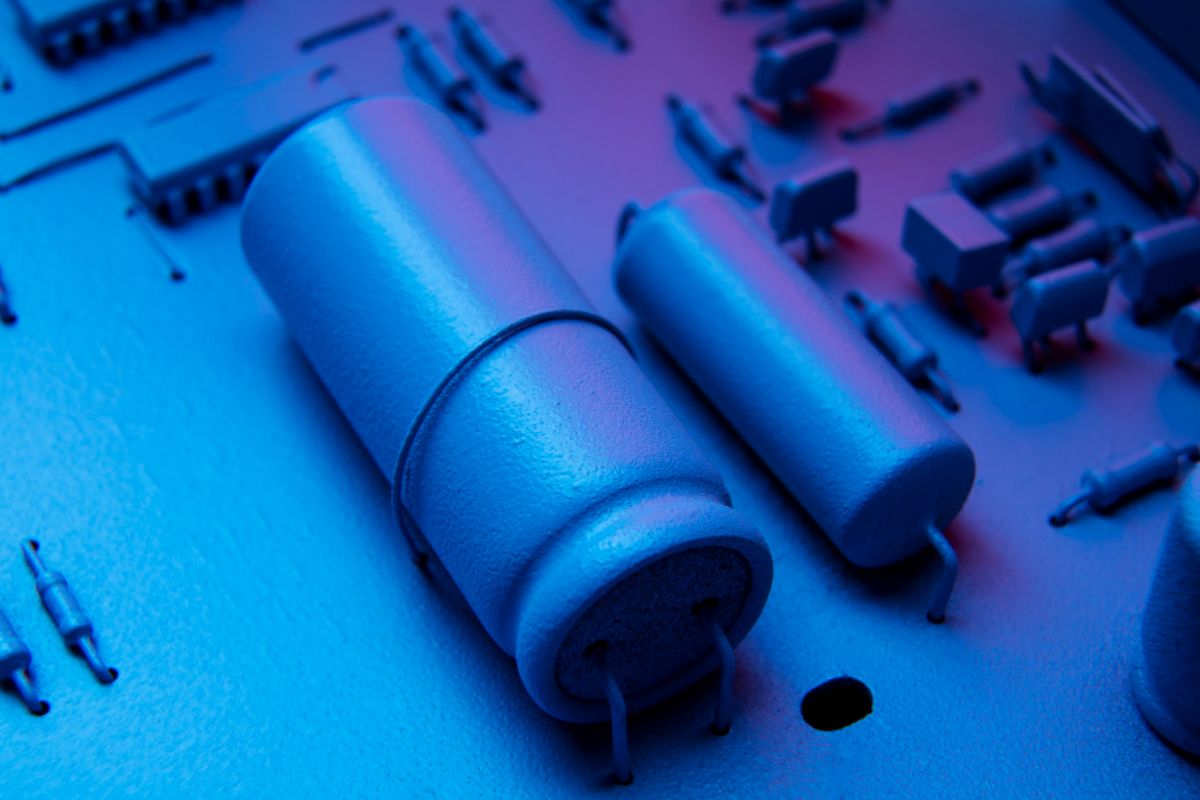

Electronic Components

In electronics, precision molding is vital for mass-producing durable and protective casings. Products such as battery enclosures, generator housings, and computer monitor frames benefit from this streamlined production process.

Household Items

Plastic’s durability, impact resistance, and corrosion protection make it an excellent choice for household products. These items benefit from a precise and efficient manufacturing approach, enhancing their longevity and everyday functionality.

Injection Molding

From automotive parts to household goods, injection molding ensures that every product meets strict specifications and quality standards. By utilizing advanced molding techniques, manufacturers can produce durable and efficient plastic items tailored to industry needs.

Their versatility extends to various applications, including battery casings, electronic components, plastic flooring, and plastic pallets. Each of these products requires precise engineering and material selection to ensure functionality and durability.

Battery casings, for instance, provide essential protection for electronic components, while plastic pallets offer lightweight yet sturdy solutions for logistics and transportation. Through the right injection molding process, manufacturers can achieve optimal performance for each application.

Plastic Mold Maker

Another plastic injection molding services in China are plastic mold makers themselves—skilled professionals responsible for designing and creating molds that shape high-quality plastic components.

From selecting the right materials to optimizing production techniques, mold makers play a critical role in maintaining efficiency and quality across industries such as automotive, medical, and consumer goods.

These experts continuously refine their techniques, incorporating advanced technologies to enhance mold accuracy and efficiency. Their ability to customize and prototype designs allows businesses to develop innovative plastic components tailored to specific applications.

Key Takeaway

Plastic injection molding services in China are crucial in producing high-quality plastic components for various industries, from automotive and electronics to construction and logistics. Whether it’s battery casings, plastic pallets, or customized prototypes, injection molding remains the top choice for businesses seeking reliable and cost-effective production solutions.

At Richfields, we specialize in providing world-class plastic injection molding services tailored to meet the needs of businesses in the U.S. and beyond. From mold design and fabrication to mass production and maintenance, we offer comprehensive solutions that ensure high-quality results.

Contact us today to learn how our expertise can help bring your plastic product ideas to life with efficiency and precision.