May 29, 2021

Plastic Injection Molding Services From Richfields Plastics

Richfields Plastics specializes in the production of high-precision plastic molds, all with the assistance of our complex injection molding capabilities and mature supply chain. Our plastic injection molding services have been trusted by a wide variety of industries across the board — from electrical, consumer goods, sports equipment manufacturing, food & beverage, and many more. Whether you’re a private individual or a professional client in need of these services, guaranteed that our plastic injection molding in China can find all the best solutions for your business model.

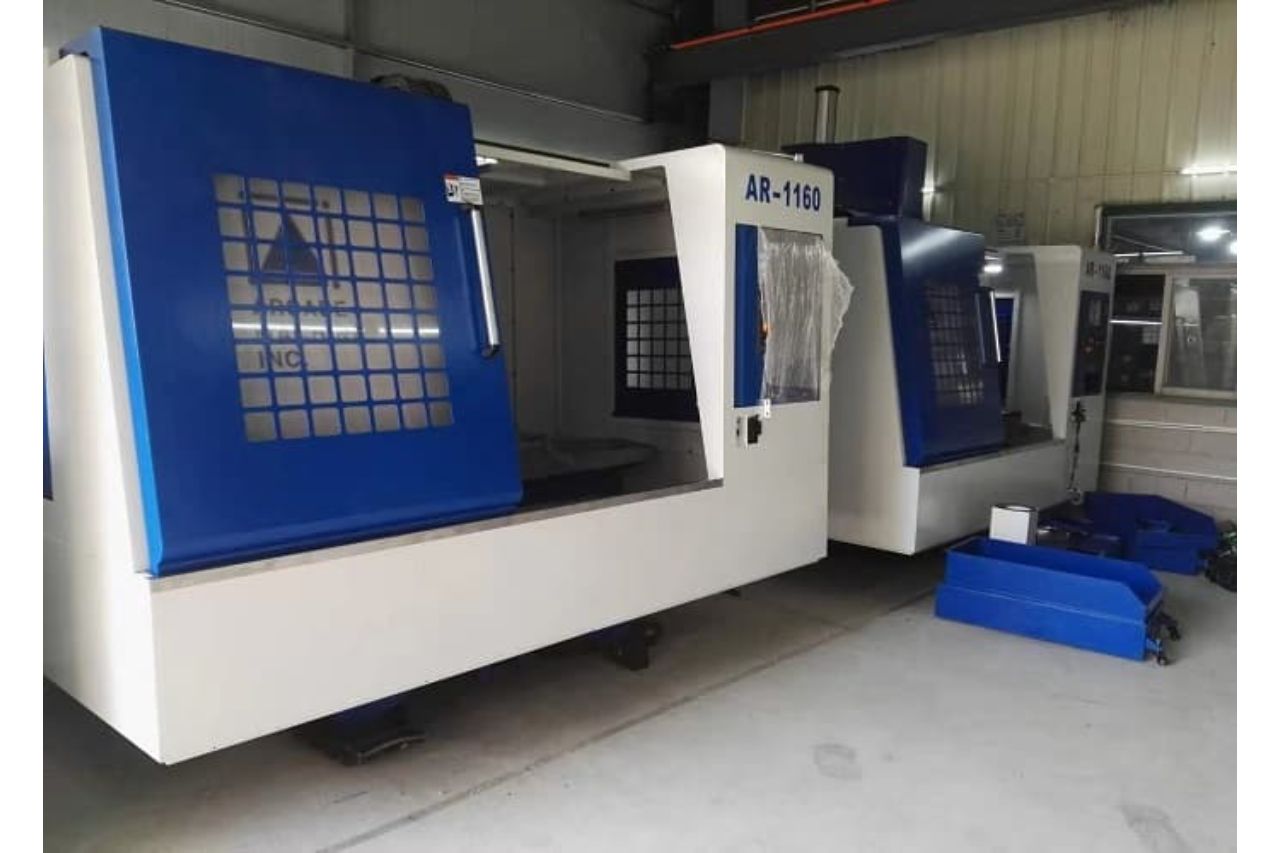

Here are Richfields Plastics, we consider our mold division to be our greatest strength and advantage. More than half of our molds are exported globally in such nations like the USA, Germany, Italy, France, Japan, Brazil, and the UK. This has all been made possible by our plastic molding-dedicated factory that can perform all types of manufacturing imaginable. We house different types of machines — from wire cutting, milling, CNC (computer numerical control), EDM (electrical discharge machining), and many more.

What makes our mold-making capacities unparalleled in the industry is our flexibility. You can trust us to assemble different types of plastic injection molded parts that have undergone the proper mold flow analysis and prototyping to achieve tight tolerances, defect-free plastic parts, and smooth finishes. Likewise, our well-designed molds can be used to produce precision parts in order to bring your concepts and product ideas to life. Read on to learn more.

Before you partner with a firm for all of your injection molding needs, it’s critical for you to understand the basics of this plastic-making technique. Most businesses will make the mistake of not knowing how injection molding works, and agreeing to conduct business with a molding company without any background.

This can result in poor product and service outcomes for your business because one: lack of knowledge about the process means you might not have an idea of how a finished part should look like. Second, is that you may not be able to discover other useful techniques that can improve the injection molding process.

With this in mind, you should first understand that injection molding is considered to be the most popular and most cost-efficient method of producing plastic parts. Molding companies like us at Richfields Plastics house different types of molding machines at varying tons — all of which can be used for high-cavitation, high production molding, or low-cavitation, high volume injection molding.

First, injection molding begins with melting a type of resin or raw plastic material in pellet form. As the resin is injected into the runners and fills the cavity of the mold, it is heated and takes the shape of the metal die prior to rapid cooling. Once the part has been successfully cooled and has adopted the shape of the mold cavities, the clamp is released and the part is ejected. Depending on the shot size and cavitation of the machine, injection molding processes may take anywhere from a few seconds to an hour.

The resin is arguably the most important raw material in any injection molding process. Choosing the right resin will determine the quality of your finished part, as well as other secondary attributes, such as shrinkage rate, color, thermal resistance, shock absorption, and many more.

At our injection molding factory in China, we have worked with a number of resin types for all of our clients. We can help you choose the right resin for the job. In need of a high impact strength resin to build electronic parts? We can assist you in determining whether ABS (acrylonitrile butadiene styrene) is the correct resin, with the help of our mold flow analysis tools. In need of metal part replacements with fiber-reinforced plastic? We can help you choose the right one.

Simply tell us what you want out of our plastic injection molding and allow us to collaborate with you for a quote that fits your preferences and business’ requirements.

Plastic injection molding presents numerous advantages to companies who are looking to create prototypes or finished products of plastic parts, without the cost drawbacks. Unlike other techniques, such as 3D printing, for example, plastic injection molding is the most economical because it is capable of high-volume production in a short lead time. Furthermore there are also a number of resin types and designs to choose from, allowing you to gauge which raw material meets your plastic manufacturing needs.

Listed further are just some of the many benefits of trusting us with our well-established injection molding services here at Richfields Plastics:

Looking for high-precision plastic injection molding services? Our manufacturing plant for plastic injection molding in China here at Richfields Plastics can meet all your business demands. We have been consistently making high-quality molds and plastic parts for our client base for several decades now. Our commitment to quality and excellent customer satisfaction has allowed us to innovate our plastic making processes to become the best in the industry there is.

Learn more about our services here! You may also contact us for more information on how we can help your business grow with plastic injection molding.