What are the materials used for plastic overmolding?

- High-Density Polyethylene

- Acrylonitrile Butadiene Styrene

- Polymethyl Methacrylate Acrylic

- Acetal Copolymer

- Polyether Ether Ketone

- Polyetherimide

- Polybutylene Terephthalate

Plastic overmolding is a manufacturing process that molds a plastic material over an existing substrate like a plastic or metal part. It creates durable and functional products for the medical, automotive, and electronics industries. When choosing the materials and designs used for plastic over-molding, you must ensure that they are fully compatible. Otherwise, the components of finished products will always be different from what you desire.

In this blog, we’ll provide you with the materials and designs that are often used for plastic overmolding, each has its own unique properties. Keep reading to learn more!

High-Density Polyethylene

High-Density Polyethylene (HDPE) is a lightweight, yet strong plastic that is commonly used in various applications. These include corrosion-resistant pipes and other materials that can withstand harsh conditions. Its high resistance to weather and impact, combined with its flexibility, allows for the fabrication of finished products with more intricate shapes. HDPE is particularly useful as it is a lightweight alternative to heavier materials.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene (ABS) is an easily manufacturable plastic material often used in automotive and electronics products at a highly affordable price. It’s equipped with good-quality chemicals and is high impact resistance, good moldability, low melting temperature, and high tensile strength — all of which are ideal for overmolding.

On top of its unique properties, ABS has an exceptionally low heat and electricity conductivity, which is the best fit for those products requiring excellent electrical insulation. This material is used for creating computer keywords, power tool housings, wall socket faces, and everything for consumer electronics.

Polymethyl Methacrylate Acrylic

Sometimes called “acrylic glass,” Polymethyl Methacrylate Acrylic (PMMA) is a strong, lightweight, and shatter-resistance plastic material often used in optical and lighting applications. It provides effective translucence (as high as 95%), chemical, clarity, UV, and wear resistance, which is why it’s one of the hardest surface finishes of any plastic on the market today.

Acetal Copolymer

Due to its impressive dimensional stability, rigidity, toughness, high strength, chemical resistance, and low moisture absorption, acetal copolymer is valued by many industries such as engineering, electronics, and automotive.

This resin material also offers greatq friction and wear resistance, which can be improved more using additives. Some of the everyday materials we used that are made with acetal copolymer are rollers, bushings, bearings, aerosol valves, and lock systems.

Polyether Ether Ketone

For components that require thermal, chemical, combustion, fatigue, and hydrolysis resistance, Polyether Ether Ketone (PEEK) offer these properties. This is often used in medical, military, aerospace, and industrial applications where part performance relies on these properties.

PEEK is an excellent choice for pistons, filters, gaskets, and pumps components.

Polyetherimide (PEI) provides strong, high-temperature stability that acts as a good electrical insulator. What’s more, PEI is deemed a more cost-effective alternative to PEEK for those who want to enhance their finished products at a lower price without compromising their quality.

This resin is usually applied for metal components like appliance housings, interior and exterior automotive parts, bearings, and medical devices. These mentioned components require flame retardance and heat resistance that PEI can provide.

Polybutylene Terephthalate

Finally, for over-molding materials, Polybutylene Terephthalate (PBTR) provides an excellent combination of electrical, thermal, and mechanical properties, such as stiffness, heat resistance, strength, weathering, and solvents.

This is all well to heat aging due to its great dimensional stability. That’s why this is commonly used in electrical connectors, headlight reflectors, grill supports, pumps, motors, and other engineering parts subjected to an extreme amount of stress.

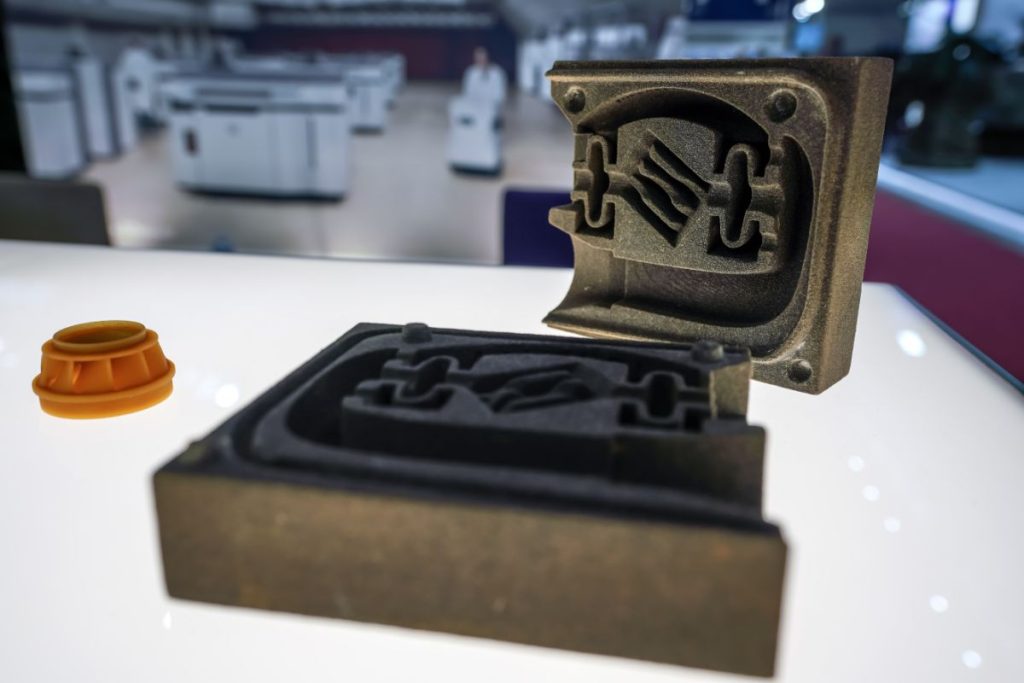

Overmolding Designs

In general, there are different over-molding design materials you can choose from. They can be harder, softer, or a blend of both. Such designs require a “grippy” or “squishy” handle. Here are the designs used for plastic over-molding.

Thickness

Designers may choose the softest TPE material for a soft touch feel, but they should be aware that the TPE’s softness may not provide much cushioning when the TPE is under a certain thickness (usually > 0.040). As the TPE gets thinner, it will become harder. They can add ribs to create thickness without overusing the material.

Modulus vs hardness

The idea that a material’s hardness is directly tied to its flexibility is a myth in the TPE industry. This isn’t always the case. For example, a material with a 65 Shore A SEBS rating might be more flexible than one with a 65 Shore A TPU rating. Instead of using Shore Hardness, flexural modulus is a better way to measure a material’s flexibility because it shows how hard it is to bend. If the flexural modulus number is high, that means the material is stiffer and less flexible.

Coefficient of friction

When two things rub against each other, like your shoe on the ground, or your hand on a table, there’s a force that makes it harder to move one thing against the other. We call this force friction. The COF (coefficient of friction) is a number that tells you how much force you need to push or pull one surface against the other surface.

Key Takeaway

In conclusion, one of the most important stages here is understanding the materials and designs used for plastic overmolding. It helps various industries to have a better idea about the material properties necessary for their finished products for long-lasting and excellent performance when used.

If you’re looking for the best plastic molding company in China, look no further than Richfields!

Contact Richfields today to learn more about our injection-molded products and services.