February 1, 2024

How Large-Size Plastic Molding Enhances Durability in Electronic Casing

Overview

- Large-size plastic molding enhances the durability of electronic casings by creating seamless, single-piece designs and ensuring uniform wall thickness.

- It provides excellent impact resistance by incorporating shock-absorbing features and advanced materials.

- The technique allows for the integration of structural reinforcements and enables excellent manufacturing, while also offering flexibility for customized designs.

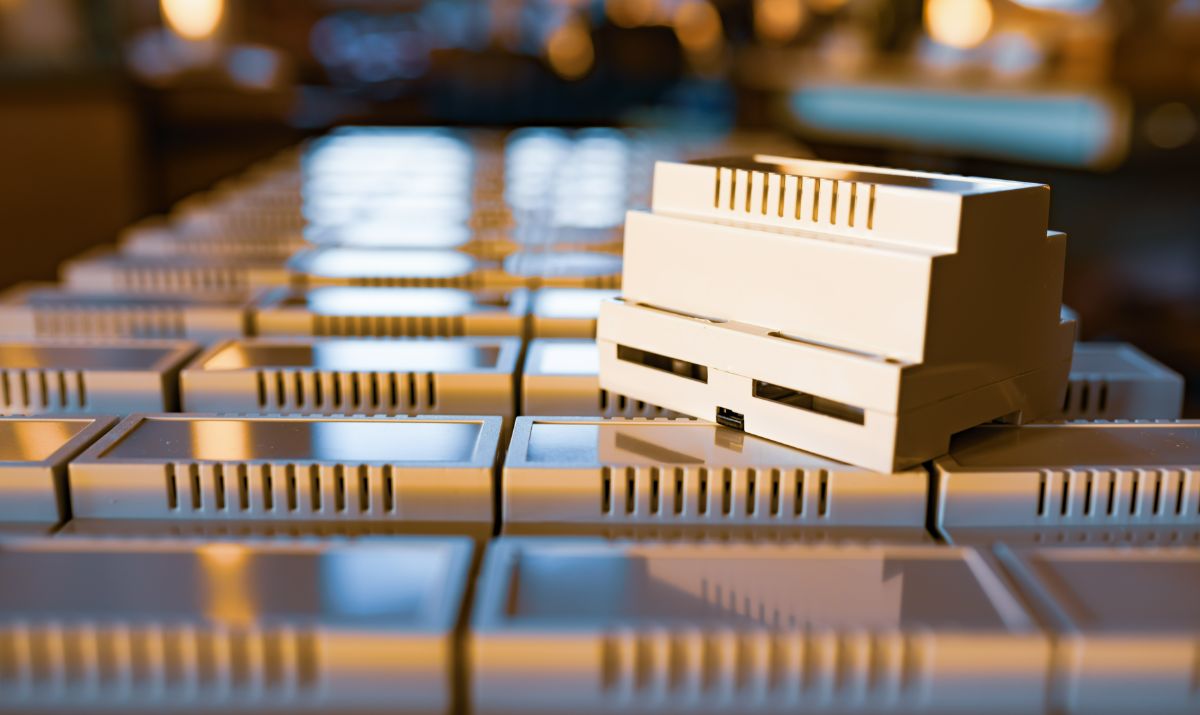

Large size plastic molding enhances durability in electronic casings by enabling the creation of seamless, single-piece designs and facilitating the use of high-performance materials like ABS or polycarbonate.

This technique ensures uniform wall thickness, distributing stress evenly, while incorporating structural reinforcements to enhance overall strength. The result is a casing that excels in withstanding impacts and environmental factors, ensuring prolonged resilience for electronic devices.

Here are some ways in which it plays a role in the durability of electronic casings:

The process offers a distinctive advantage in the fabrication of electronic casings by enabling their construction as a single, seamless piece. This eliminates the necessity for joints and seams, which are susceptible to becoming weak points in the overall structure.

The resulting unified casing exhibits enhanced strength, as there are no vulnerable areas where breakage or damage could occur. This design feature contributes significantly to the overall robustness of these casings, ensuring a more reliable protective enclosure for the internal components.

Electronic devices frequently face the risk of accidental drops or impacts in various usage scenarios. The utilization of large-size plastic molding offers a strategic solution to enhance the casings’ impact resistance. It often incorporates advanced shock-absorbing features, which may include impact-resistant coatings, layered structures, or built-in cushioning materials.

By combining materials with a thoughtfully engineered geometry, large-size plastic molding ensures that electronic casings can better endure the stresses imposed by accidental drops or impacts, thereby safeguarding the internal components from potential damage and extending the overall lifespan of the device.

The versatility of large-size plastic molding proves advantageous in the integration of structural reinforcements directly into the design of such casings. This method allows for the incorporation of elements including ribbing, gussets, and other features strategically positioned to enhance the casing’s overall strength and stiffness.

By introducing these reinforcements, the casing becomes more resilient against deformation or breakage, offering excellent protection to the internal electronic components. The added structural integrity not only fortifies the casing against potential stresses and impacts. It also contributes to the longevity of the device by ensuring that it can withstand various external forces without compromising its form or functionality.

This manufacturing technique, often exemplified by processes like injection molding, allows for the production of entire casings or complex parts in one seamless piece. This reduces the likelihood of defects and facilitates a more efficient and reliable production cycle.

Moreover, large-size plastic molding provides the precision and consistency necessary for the seamless integration of various features, such as ports, buttons, and structural reinforcements, into the final product.

The uniformity achieved in this process not only enhances the aesthetic appeal of the electronic devices but also ensures that each unit meets high-quality standards, contributing to an efficient manufacturing workflow.

This process also provides a versatile and adaptable manufacturing process. This allows for the integration of unique shapes, sizes, and features in a single molding cycle, offering flexibility and efficiency. As a result, it produces intricate details, textures, and specific design elements.

The use of diverse molds and tooling configurations supports the production of a broad range of customized designs without sacrificing manufacturing efficiency. This capability not only caters to the varied aesthetic preferences of consumers but also addresses the specific functional requirements of casings.

Large-size plastic molding enhances durability in electronic casings by utilizing durable materials, ensuring structural integrity, offering design flexibility, and incorporating shock-absorbing features. Additionally, it effectively strengthens casings, providing enhanced resistance to impacts and accidental drops. This technology plays a crucial role in protecting electronic devices and prolonging their lifespan.

Are you in need of high-quality large-size plastic molding solutions for your manufacturing needs? Look no further than Richfields Corporation. With a proven track record of delivering durable and precisely engineered casings, we specialize in providing tailored solutions to enhance impact resistance in electronic devices. Our state-of-the-art facilities, experienced team, and commitment to customer satisfaction make us the ideal partner for your plastic molding requirements. Contact us today to discuss your project and discover how Richfields can help you.