What are the injection molding trends in 2021?

- Shift towards sustainable practices

- Innovations in bioplastics

- Exploring raw material alternatives

- Focus on automation

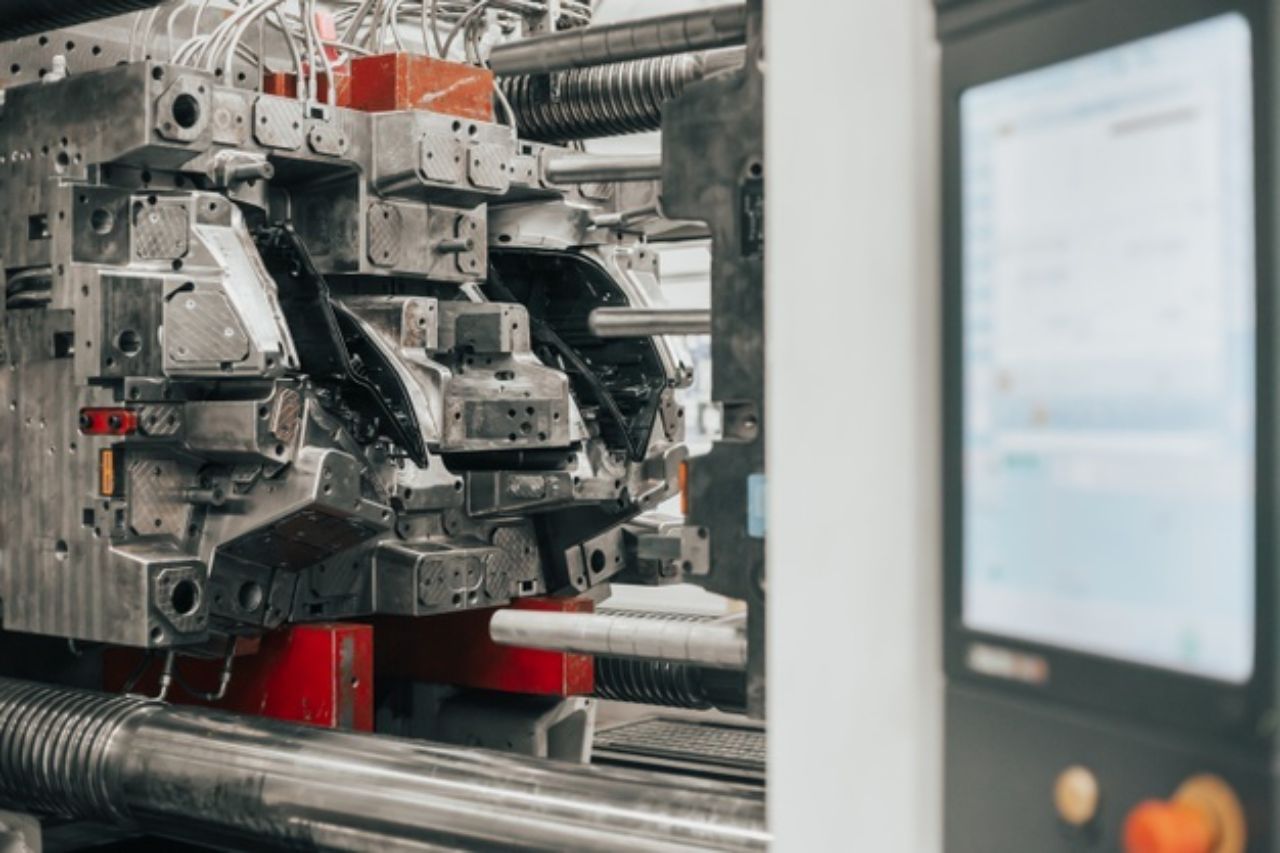

Injection molding continues to be a reliable form for the manufacture of lightweight, but durable plastic parts for different industries. No one certainly predicted just how essential injection molding will be for many economic sectors, but it has definitely seen a gradual but sure progression throughout the years. Almost 150 years since its inception, injection molding trends in 2021 continue to make waves in bringing innovation for assembled plastic parts and mass-produced products.

However, as requirements vary and businesses are looking to turn towards plastic molding for more cost-effective solutions, the molding firms across the world must be able to adopt.

Most of the current trends in injection molding aren’t new, but they were borne out of a desire to make plastic molding the most viable and most affordable alternative. One trend in particular expresses a positive outlook on plastic injection molding becoming a sustainable mode of production. Other trends express hope for plastic manufacturing firms to come up with inventive solutions and other innovations for added consumer value.

Whatever it is, resin manufacturing technology continues making waves in manufacturing in response to economic, political, and even social climates. Plastic injection molding is here to stay for good and these trends, but consumers and stakeholders are definitely just scratching the surface. Read on to learn more.

Shift Towards Sustainable Practices

It’s not a surprise that plastic makes up a majority of the waste that goes to global landfills. The recycling rate is also somewhat poor, with only less than 10% of waste or scrap plastic recycled — others go to dumps, the ocean, or simply get burned. Nothing about the current plastic situation seems recyclable, which poses a challenge for many injection molding companies to find more ecologically-friendly and sustainable options.

No doubt that today’s plastic molding giants will also want to become a part of this broader cultural shift towards sustainability. While business decisions may vary from company to company, manufacturers are nonetheless becoming more and more aware of how they can reduce their waste.

Injection molders, for example, may start thinking about making changes to the kind of machines they use in order to conserve energy. They may also start tweaking their processes so as to produce the least amount of scrap for every injection molding cycle.

While there is a great deal of promise for injection molders to turn towards sustainable practices, they also have to consider how these changes will affect their capacities to satisfy tight product tolerances or meet crucial requirements.

Innovations In Bioplastics

Another sustainable trend in injection molding seeks to take advantage of a specialized type of material known as bioplastics. These are plant-based resins used to produce more eco-friendly products that can be attractive to consumers seeking to reduce their carbon footprint.

The great thing about bioplastics is that the manufacturing process is significantly less resource intensive compared to petroleum-produced plastics. Bioplastics are biodegradable and when used in large scales such as in injection molding, it can create and steer momentum for other sustainables.

Exploring Raw Material Alternatives

Different types of plastics are used in injection molding processes in order to satisfy industry specific requirements. Some of these raw materials include acrylic, ABS, polyethylene, polystyrene, and the like. On their own, these materials offer excellent benefits to consumers and clients. But as the injection molding manufacturing model moves towards maturity, both end-consumers and manufacturers are likely exploring other raw material options, like composites.

Plastic composites are plastics that have been reinforced with other materials such as fiber, particulates, powders, fillers, and others, in order to improve durability and stiffness.

Composite use has been around for several years in the plastic molding domain due to their high-performance capabilities. In fact many car makers or even airplane manufacturing companies continue to reap the benefits of fiber-reinforced plastics because they’re far more durable, versatile, and cost-effective than others.

Focus On Automation

Automation has been critical not only for injection molding but for many industries as well. This is arguably the most effective solution to maximize production capacity, productivity, while also keeping prices as low and as manageable as possible.

With automation, injection molding processes offer operators with more control of the process. Project managers, process engineers, and product teams should take hold of this opportunity to incorporate software and prototyping platforms to facilitate advanced mold-making.

A good example is mold flow analysis which makes use of software to predict an entire injection molding cycle for a specific mode. Injection molding companies can use this technology in order to maintain a competitive advantage. Intelligent platforms such as this allow them to predict mold behavior, shrinkage rage, and other factors that affect the quality and scrap rate of the finished part.

Key Takeaway

Tackled in this short read are just some of the key injection molding trends in 2021 that the manufacturing industry and other key stakeholders should be on the lookout for. The fact is, injection molding is here to stay but in order to keep up with demands, it should be able to adjust to current and emerging trends.

Nevertheless, as the landscape continues changing, there is no doubt that the plastic molding industry will continue coming up with ingenious ways of providing products and services to customers.