What’s the difference between injection molding and die casting?

- Die Casting

- Injection Molding

- Cost-Effectiveness

- Degree of Accuracy

- Product Value

For mass-producing goods, there are tons of methods to choose from. Manufacturers may choose to invest in either injection molding or die casting. These methods are extremely similar but can achieve different results. When it comes to manufacturing goods, this is a major decision to make. Which is better? Which one should you invest in? To help you make a decision, here are the advantages and disadvantages of both.

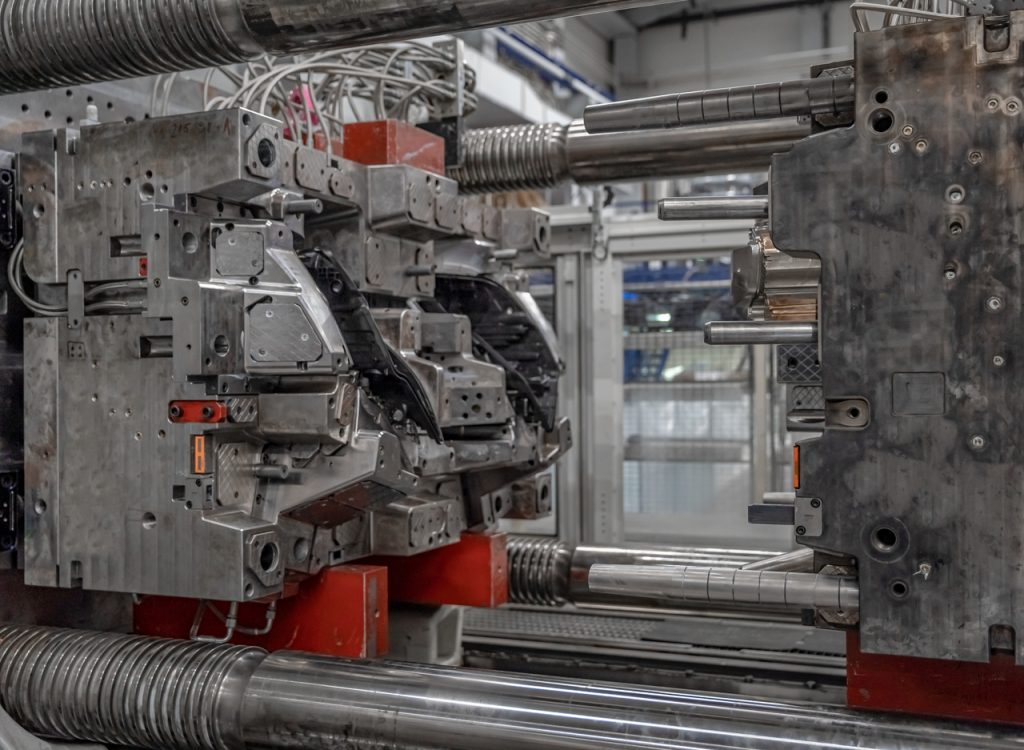

Die Casting

Die casting is a fairly common term. It’s quite similar to the process of plastic injection molding. However, die casting is special as it uses metal. The metal is melted and poured into steel molds. The metal cools to its desired shape before being removed from the die casting machine. There are various tools and household objects that can be made from die casting. This can include metal dice, a hammerhead, and figurines. The products made with die casting are more durable as they are made from metal. If you are looking into producing quality products using metal compounds, die casting should be one of your choices.

Injection Molding

Plastic injection molding is the most popular and widely used plastic forming method. It’s a process that can create a wide variety of products with different shapes, sizes, and production speed. A lot of everyday objects can be made from plastic injection molding. Objects such as toys, combs, plastic dinnerware, and plastic organizers. Injection molding can also be used in other materials such as metal and glass, but the most common use for this is plastic. First, a manufacturer has to have a finished design ready for use. The raw plastic material is then melted and fully liquefied. The melted plastic will be injected into the mold until completely filled to begin taking shape.

Cost-Effectiveness

Plastic injection molding has the highest cost-effectiveness. It’s cheap to gather materials and scrap to recycle into a new project. The waste produced by plastic injection molding is also significantly lower than other methods. When done correctly, injection molding can produce consistent, high-quality products in record time. This process can also be automated to reduce labor costs.

Similarly, die casting uses the same methods. However, for higher quality metals, it can get expensive and has a slower turn-over as different materials have varying melting points. It would be best to strategize the volume of materials you’re planning to use for your next production. The molds used can also be used over and over due to their inherent durability. The products made with die casting are very durable and have a long service life.

Both are cost-effective in nature. Both of these forming methods have tons of similarities. It all boils down to what you’re trying to manufacture. If you want to quickly mass-produce high-quality plastic products, plastic injection molding is the obvious choice. However, if you plan to create steel pipes, metal faucets, or electronics, die casting is the better choice in this situation.

Degree of Accuracy

The degree of accuracy for both depends on how the process and the mold are engineered. If a mold is not properly made and engineered, the entire process can be compromised. In general, plastic injection molding and die casting can produce accurate results. It’s possible to computerize both to increase production efficiency. However, die casting may be a bit tricky as metals behave differently from plastic.

Product Value

Both products made from these forming methods can be priced accordingly. However, plastic injection molding has a clear advantage. Plastic injection molds have the ability to accommodate different polymers and plastics to birth different results. The technologies being researched and developed today allow polymers and molds to increase their strength with the use of fillers. These fillers can include fiberglass materials to expand the use of manufactured products to other industries.

Tons of materials used by aircrafts, vehicles, and pharmaceuticals are blended with various fillers to increase the strength and create different properties. You get more value out of a specific mold with these different filler blends. While different fillers are being used for the polymer, fillers can also be used to increase the strength of plastic molds. All of these amazing benefits are ready without sacrificing speed and accuracy.

Key Takeaway

If you’re using injection molding or die casting, you can produce amazing results depending on what you want to create. However, if you desire a forming process with tons of flexibility, value, and cost-effectiveness, plastic injection molding is highly recommended. There will always be a demand for plastic injection molded parts and as technology continues to improve, more industries will need the value of this particular forming method.