December 9, 2024

Injection Molded Plastic Pallets vs. Wooden Pallets: Which is Better?

Overview

- This article compares injection-molded plastic pallets and wooden pallets, highlighting key factors such as durability, maintenance, environmental impact, and cost-effectiveness.

- By exploring the strengths and limitations of each type, businesses can make an informed decision based on their specific needs.

- Richfields Corporation offers tailored solutions, ensuring high-quality, durable plastic pallets that enhance operational efficiency and long-term savings.

In the logistics and supply chain industry, pallets are essential for the efficient storage, handling, and transportation of goods. Among the most widely used pallet types are injection-molded plastic pallets and wooden pallets.

This article will provide a detailed comparison between these two. By understanding these differences, businesses can make informed decisions tailored to their specific operational needs. Let’s delve into the features of each type to determine which option is best suited for your business.

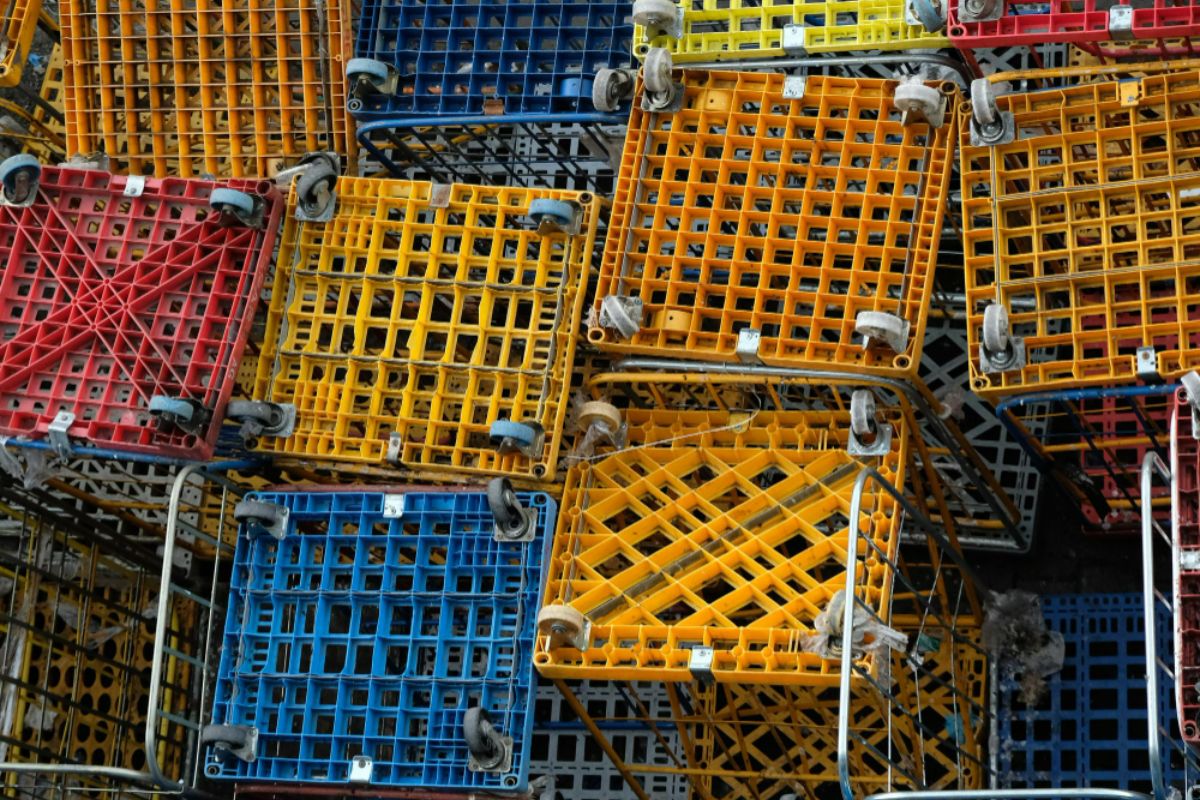

These pallets are produced using a sophisticated manufacturing method that involves pouring molten plastic into molds to produce long-lasting, high-quality goods with uniform dimensions. It provides strength and resilience, making them suitable for a wide range of applications, even in demanding environments.

Because these pallets are resistant to bending, breaking, and splintering, one of their main advantages is their exceptional durability. They are highly resistant to moisture, mold, and pests, making them a hygienic and long-lasting choice for industries like food and pharmaceuticals.

These pallets are reusable and easy to clean, providing businesses with a cost-effective solution over time. Richfields Corporation specializes in offering these pallets that meet the specific needs of various industries.

Wooden pallets have long been the traditional choice for transporting and storing goods across various industries. Built by nailing or screwing wooden planks together, these pallets provide a sturdy platform that ensures stability during handling and shipping.

Sourced easily from local suppliers, wooden pallets are often more affordable than other options, making them an economical solution for businesses seeking a cost-effective yet reliable choice for their operations.

Additionally, they are highly repairable. Damaged planks can be replaced or fixed with minimal effort, extending the pallets’ lifespan and further enhancing their practicality. This blend of affordability, accessibility, and ease of maintenance has cemented wooden pallets as a staple in the logistics industry.

When deciding between injection molded plastic and wooden pallets, there are factors to consider to determine which option best suits your business needs.

The plastic pallets are highly durable and designed to withstand extreme conditions, making them ideal for long-term use. They are resistant to cracking, splintering, and warping, even in harsh environments, providing a longer service life.

In comparison, wooden pallets are more susceptible to damage from moisture, pests, and rough handling, leading to a shorter lifespan. While they are cost-effective initially, they may require frequent replacements.

The plastic ones are easy to maintain, requiring simple cleaning to keep them hygienic and in good condition. Their non-porous surface prevents the absorption of moisture, mold, or bacteria. This makes them ideal for industries that need to meet strict cleanliness standards.

The wooden types are more prone to absorbing dirt, moisture, and contaminants, which can lead to hygiene issues over time. While they can be cleaned, these pallets often need more effort and regular upkeep to maintain their cleanliness.

Plastic pallets are more sustainable in the long run, as they are made from recyclable plastic and can be reused many times before being recycled. However, their production process does use more energy, and not all plastic pallets are recyclable depending on the materials used.

Wooden pallets, on the other hand, are biodegradable and made from a renewable resource, making them a more environmentally friendly option in terms of raw materials. They may be recyclable, but the demand for wood can lead to deforestation if not sourced responsibly.

The plastic types offer greater flexibility when it comes to design and customization, as they can be molded into various sizes, shapes, and configurations to suit specific needs. They can also be equipped with added features like RFID tags, which are used in tracking inventory.

Wooden pallets, while more limited in design options, can still be modified in size and strength by adjusting the number of planks used. However, plastic pallets offer a broader range of customization options to meet specific logistical and operational requirements.

As mentioned, wooden pallets are more affordable upfront, making them a budget-friendly choice for businesses with short-term or limited-use needs. However, they often require more maintenance and frequent replacements, leading to higher long-term costs.

In contrast, plastic pallets come with a higher initial investment, their durability, low maintenance, and longer lifespan translate to significant cost-saving over time. For high-volume operations, plastic pallets can ultimately be more cost-effective in the long run despite the higher upfront cost.

Richfields Corporation offers an ideal solution for businesses seeking durable, customized plastic pallets. With extensive expertise in the industry, we ensure that each pallet is high-quality and has long-term performance.

Our advanced manufacturing processes guarantee precision, making the pallets strong enough to handle challenging environments while maintaining cost-effectiveness. Our team is committed to providing tailored solutions, offering customization options to meet the unique needs of each business.

The choice between injection pallets and wooden pallets comes down to the specific requirements of your business. Richfields Corporation specializes in providing high-quality, customizable plastic pallets that meet the diverse needs of businesses across various industries. Contact our team today.