What are the steps in choosing plastic for car battery molds?

- Define battery requirements

- Check material compatibility

- Assess temperature resistance

- Examine mechanical properties

- Ensure dimensional stability

- Determine surface finish

- Evaluate overall cost

- Consider manufacturability

Overview

- Understanding the significance of selecting the appropriate plastic for car battery molds is paramount to ensure both durability and efficiency.

- Through accurate consideration of these criteria, manufacturers can secure the production of high-quality battery components.

- The skilled team at Richfields can deliver valuable assistance in defining battery requirements and advising on materials with optimal compatibility, temperature resistance, and mechanical properties.

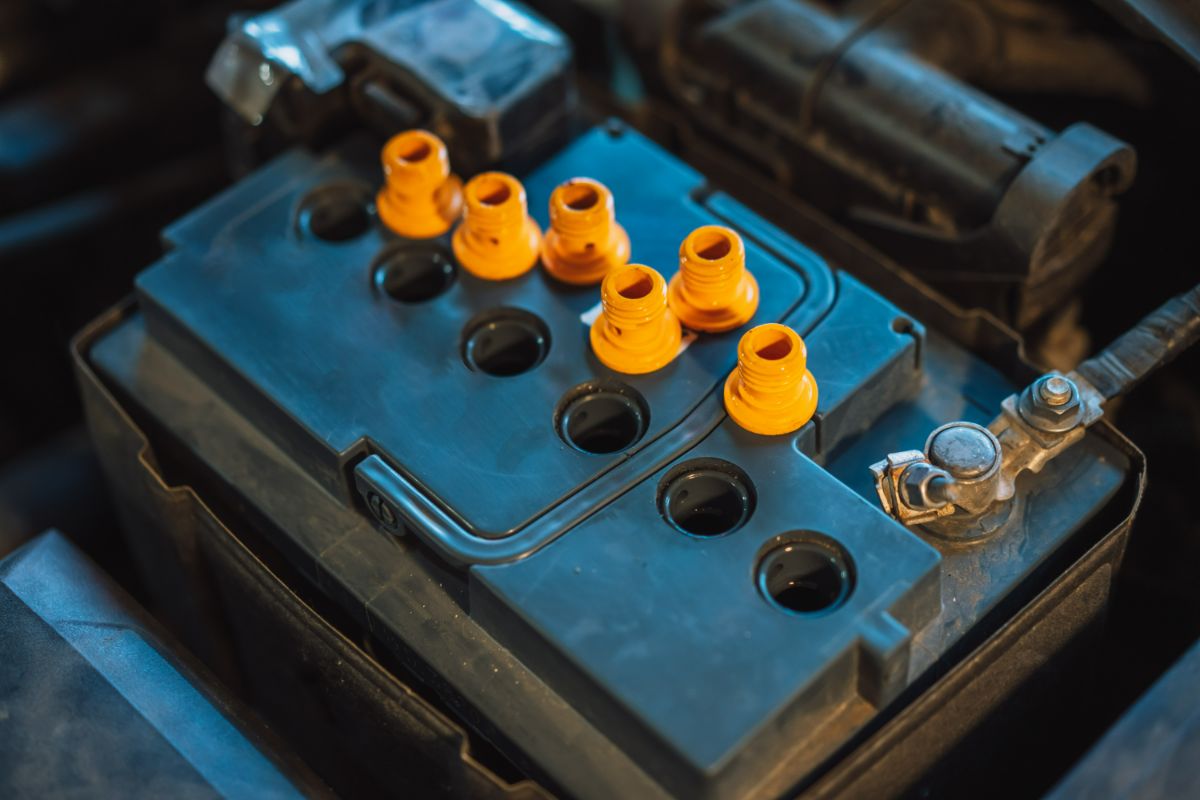

Car batteries require high-quality components to maintain a vehicle’s performance and reliability. One of the most crucial decisions is how to choose the right plastic for car battery molds to ensure efficiency and durability.

Choosing the best molds is important for consistent outcomes whether you’ll involve injection molding or any other plastic manufacturing procedures. In this article, let’s explore the steps in choosing the right plastic for car battery molds to optimize the best results.

Define Battery Requirements

Plastic material and molds for car batteries are important to be considered and aligned with the distinct requirements of various automotive applications. The appropriate placements depend on the battery requirements. It is important to consider these aspects to ensure that the selected plastic can endure the challenging conditions of battery production and use.

For instance, Polypropylene (PP) is commonly used for car battery casings due to its excellent chemical resistance, low cost, and high impact strength. It can also withstand exposure to battery acid and other chemicals, which ensures long-term durability.

Check Material Compatibility

Compatibility with the chemicals used in battery production is essential to be regarded. Polyethylene (PE), for instance, is resistant to an expansive range of chemicals including acids and alkalis, which makes it suitable for producing high-quality battery components with consistent performance and longevity.

This compatibility with the chemicals will guarantee that the plastic maintains its structural integrity and functional properties over time even in the presence of corrosive or reactive battery components.

Assess Temperature Resistance

Some plastic materials can resist the high temperatures of a car battery for they normally heat and are even suitable for car battery mold. Polyphenylene Sulfide (PPS) is a sample for its high-performance thermoplastic which is recognized for its excellent heat resistance.

PPS can endure an elevated temperature reaching a melting point above 270°C (518°F) during the manufacturing and operation of car batteries. It is a popular choice for car battery molds since it maintains its structural integrity.

Examine Mechanical Properties

It is important to be thorough in evaluating a battery’s mechanical properties like its flexibility, strength, tolerance to vibrations, adhesion, cycling stability, and thermal expansion. These elements distinguish the material’s ability to withstand the stresses and pressures encountered during the injection molding process.

Facilitating proper part formation and dimensional accuracy, a plastic with sufficient mechanical strength ensures that the mold can hold its shape and integrity. By prioritizing these mechanical properties, manufacturers can enhance the reliability and longevity of their molds, ultimately resulting in high-quality battery elements.

Ensure Dimensional Stability

Dimensional stability requirements for car battery molds such as precision, tolerance control, temperature stability, material selection, and machining accuracy are important. These key considerations ensure the accuracy, consistency, and quality of the batteries being produced.

Some plastic materials are known for their excellent dimensional stability like the Polyether Ether Ketone (PEEK). It is recognized for its exceptional dimensional stability even under high temperatures and mechanical stress. This makes it suitable for demanding automotive applications.

Determine Surface Finish

The desired surface finish of battery components is crucial in selecting a plastic material for car battery molds. You can opt for Acrylonitrile Butadiene Styrene (ABS), which is known for its smooth surface finish and ease of processing.

Ensuring that the selected material can reach the desired surface finish contributes to the overall grade and appearance of the battery components. By prioritizing this factor, manufacturers can produce battery parts with the desired visual appeal and performance characteristics.

Evaluate Overall Cost

The overall cost of plastic for car battery molds is important to be weighed for knowledgeable decisions that optimize both financial resources and product quality. Consider some factors like the material type and grade, quantity and size of molds, and the complexity of mold design.

It is also essential to consider the material processing costs, material waste, scrap, supplier, and market factors to effectively manage the overall cost while maintaining the quality of car battery molds.

Consider Manufacturability

Plastic molding is a popular choice for manufacturers due to the advantages it offers in the production of car battery molds. These benefits make them an attractive option for those who are seeking efficient and versatile solutions for producing high-quality battery molds.

Some of the advantages are its cost-effectiveness, design flexibility, reduced weight, faster production, improved corrosion resistance, and reduced tooling costs. Manufacturers can improve overall manufacturing performance by evaluating these factors.

Key Takeaway

How to choose the right plastic for car battery molds involves a systematic approach. These criteria are equally important to ensure high-quality battery elements.

Richfields’ expert team can assist in defining battery requirements and guiding materials with optimal compatibility, temperature resistance, and mechanical properties. You not only benefit from our technical prowess but also our dedication to delivering top-quality results. Contact us today to elevate your car battery mold project to new heights of excellence!