November 12, 2025

Custom vs. Off-the-Shelf Storage for Logistics

Overview

- Effective warehouse storage is essential for smooth logistics and operational efficiency. Procurement officers often face the challenge of choosing between customized and pre-made solutions, both of which offer distinct advantages.

- Custom storage, built to match inventory requirements, maximizes space and supports long-term efficiency. Off-the-shelf options provide immediate availability and standardized dimensions, making them useful for general or temporary storage needs.

- Richfields offers expert custom injection-molded solutions tailored for reliable, high-performance logistics. Understanding the differences helps businesses select the solution that best fits their workflows, product types, and operational goals.

Proper storage is a cornerstone of successful warehouse operations. To maintain efficiency and accessibility across the supply chain, procurement officers must select a suitable option. The decision often comes down to customized solutions vs. off-the-shelf storage for logistics. Businesses need to find the options that best aligns with their efficiency needs.

In China, large-part injection molding is a primary choice for manufacturing custom products. It provides flexibility to meet storage requirements more precisely than ready-made units. Richfields provides services for creating tailored units designed for complex containment needs. Read on to see how each option compares.

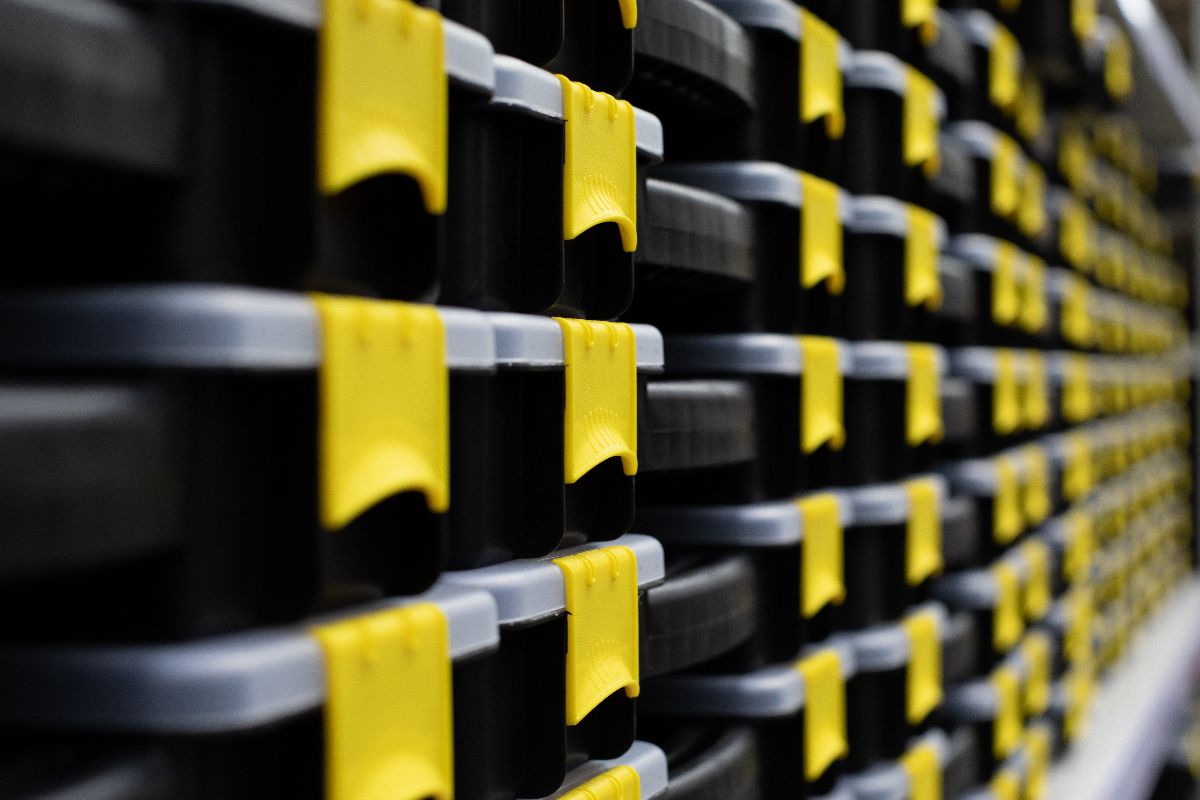

Customized storage —pallets, stackable bins, or modular containers— is built to match the specifications of a company’s products. They’re widely efficient across different industries, but they’re especially vital in automotive and electronics, where precise handling is required for protecting uniquely shaped components.

Each unit is built to fit the specific size, weight, and layout of warehouse items. They eliminate the inefficiencies of generic solutions, allowing warehouses to maximize storage space. This precise alignment reduces handling mistakes and keeps inventory properly organized throughout distribution.

For procurement officers, the real advantage is in the control custom storage provides. Through processes like injection molding, durable units like plastic pallets or bins can be intricately designed with unique dimensions that match the products. This simplifies operations and also gives businesses a competitive edge through greater precision.

Custom storage offers the following advantages:

Even with their many advantages, they require more planning and coordination. Procurement officers must clearly define requirements —item dimensions, weight ranges, handling methods— before manufacturing begins. This planning stage takes more effort than simply ordering ready-made storage, but it ensures that the final product performs its intended function for the long term.

It’s also no secret that tailored carriers require a higher initial investment compared to standard containers. The costs reflect the design, tools, and expertise involved in their creation. However, while the expense may be higher, the precision that goes into creating custom units ensures their lasting durability.

They have the following considerations:

Unlike customized alternatives, off-the-shelf options are pre-manufactured and widely available for quick use. Warehouses handling standard inventory can opt for mass-produced containers as a convenient, temporary option.

Generic storage options simplify logistics management by providing ready-to-use alternatives. Since these units are pre-designed and widely available, procurement officers can deploy them immediately. This saves time and coordination needed for a custom design.

They also ensure consistency across operations. Standardized sizes fit common warehouse layouts and handling equipment, which supports easier integration. This predictability speeds up material handling and allows warehouses to maintain steady efficiency in fast-paced manufacturing conditions.

Off-the-shelf alternatives provide these advantages:

While accessible, they lack many features required for specialized logistics. Their generic design can leave warehouse space underutilized, and they may fail to meet the unique requirements of complex supply chains.

Their uniformity can also limit adaptability to changes in the inventory profile. When logistics teams rely on these units, they may find themselves investing in frequent replacements or workarounds. These inefficiencies can outweigh initial cost savings over time.

Their potential drawbacks include:

Ultimately, the choice depends on the warehouse’s operational goals and constraints. Procurement officers must carefully evaluate how they align with long-term logistics needs.

Do the products require specialized containment, or will general-purpose storage suffice? Special storage units are a better fit for the long run because they match the exact size, weight, and layout of your inventory. These support efficient workflows and reduce mishandling. Pre-made options can also be useful, but are more suitable for temporary use.

Custom carriers are ideal for fragile, oversized, and irregularly shaped products. Meanwhile, off-the-shelf options work best for uniform, standard goods. Procurement heads must determine whether existing stock or future product lines will fit into standardized containers or racks. If not, tailored storage is the better choice.

Budget and timing are also key factors. Custom units involve higher costs and longer delivery times due to the design expertise and precise manufacturing required. However, they provide superior long-term support and efficiency. If immediate deployment is essential, choose ready-made options as a temporary choice.

At Richfields, we manufacture durable, customized storage solutions using advanced large-part injection molding techniques. Our expertise allows us to produce high-quality modular crates, pallets, and bins tailored precisely to your inventory needs.

We collaborate closely with clients to understand their logistics requirements. By assessing the factors mentioned above, we deliver storage units built for consistent performance and long-term reliability.

The choice between custom vs. off-the-shelf storage directly influences the workflows in logistics operations. Procurement officers must evaluate their warehouse’s needs and product types carefully to determine which option best aligns with their goals.

With Richfields’ expertise in custom injection-molding, you gain strong containment units for optimal logistics performance. Contact us today to explore how we can support your operations.