Are you looking for the best provider of custom plastic injection molding in China? Richfields Plastics can meet all of your injection molding requirements for any kind of product imaginable. From custom parts, aftermarket goods, to OEM products, their plastic injection molding in China is the most reliable service for a variety of companies. With a focus on precision parts, complex designs, large mold assemblies, and other kinds of prototype manufacturing, you can rely on Richfields’ custom plastic part manufacturing no matter what industry you belong to.

What Is Custom Plastic Injection Molding?

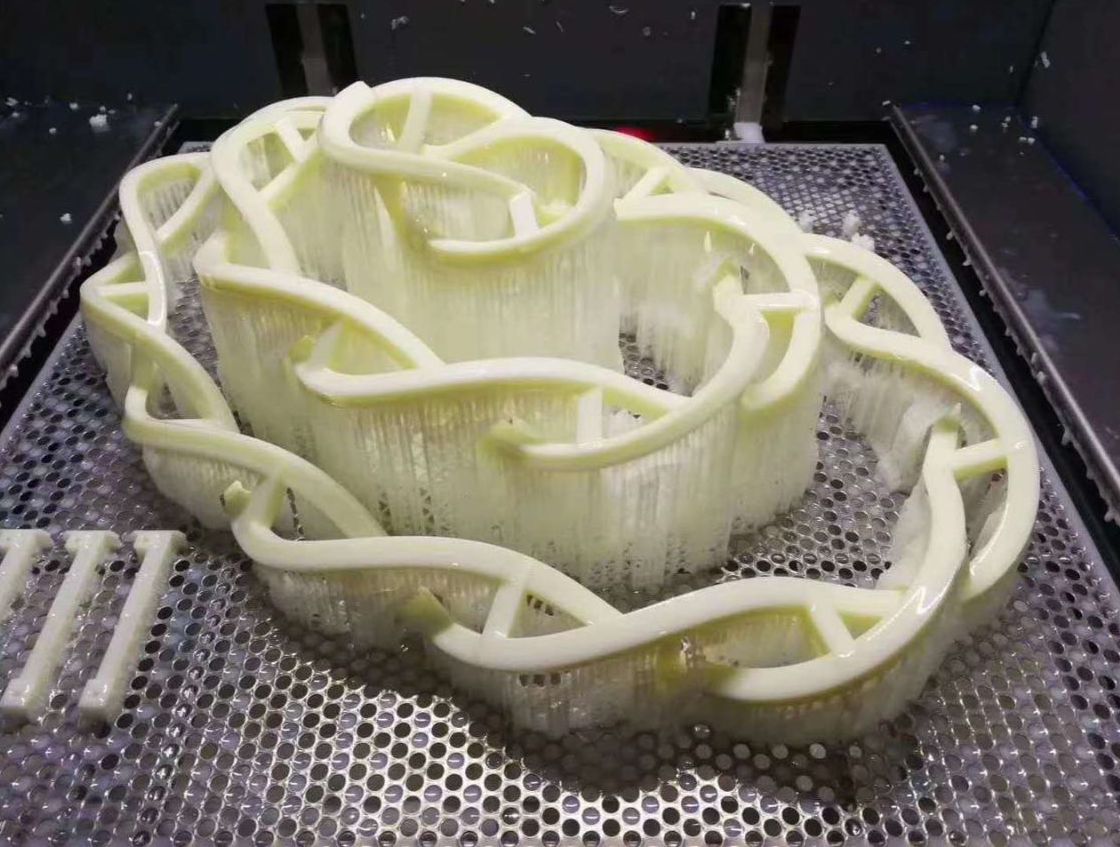

Plastic injection molding is a type of plastic fabricating method wherein pellets of resins are molten and then injected inside a mold. After cooling, the resulting product is ejected from the mold and will undergo further assembly or direct market distribution — as is the case with prototypes.

With this in mind, custom plastic injection molding requires high precision and attention to detail. If you’re in need of this type of service, you want to make sure that your manufacturer’s machines, equipment, and capabilities are adequate to perform the manufacturing of custom parts and designs.

For example, if the plastic is to be used for structural and industrial purposes, the resulting product must be durable enough to withstand different environmental conditions. Your injection mold manufacturer must be able to design a product that meets stringent specifications and achieve tight tolerances, especially for custom-built components.

Fortunately, Richfields Plastics is capable of these and more. They specialize in high-volume and high-capacity injection molding for ISO-certified and high-quality products that meet the client’s expectations. Read on to learn more.

Reverse Engineering

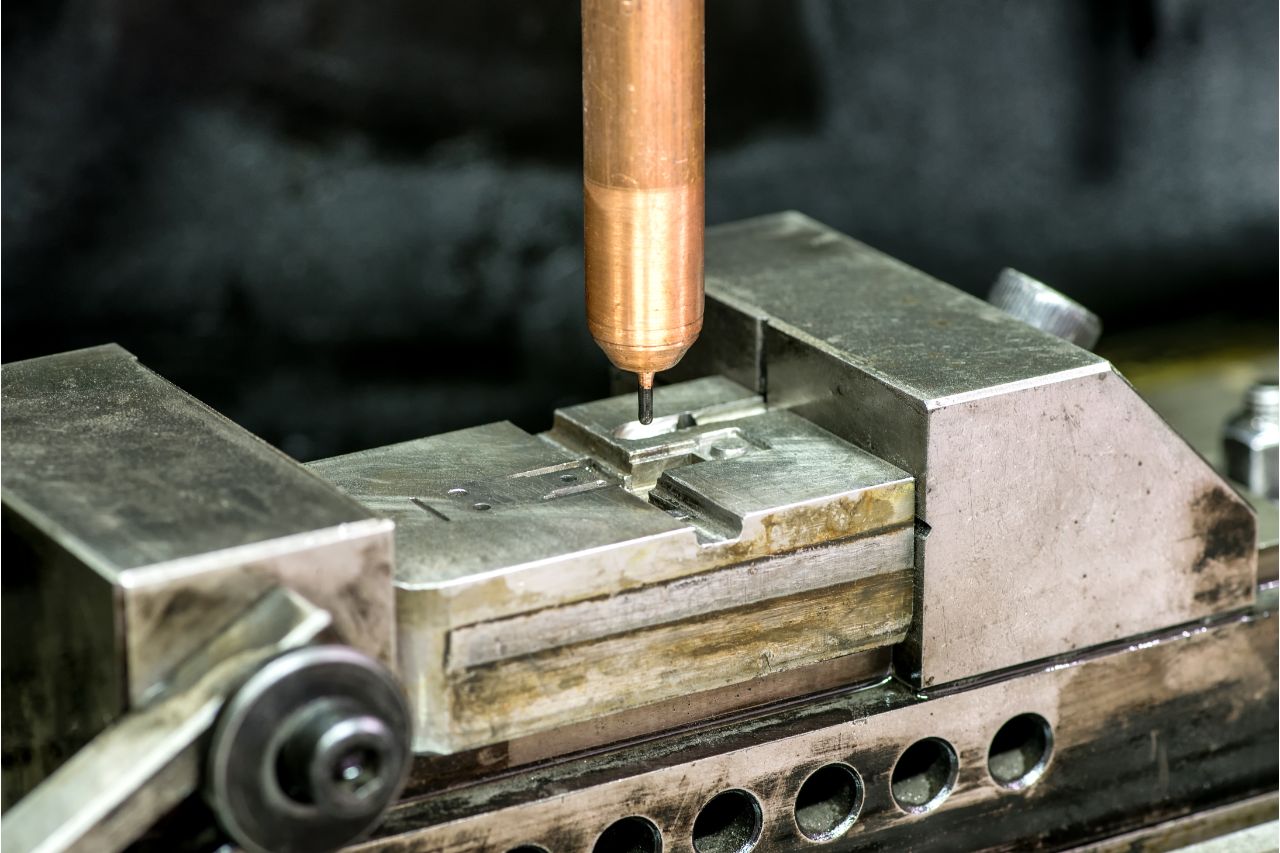

As mentioned before, precision of design is essential in injection mold manufacturing. Tons of factors can affect this, such as expertise of the manufacturer, machinery, implementation of different techniques, and the like.

Reverse engineering is one of these techniques that focus on the development of custom designs through extensive studying and improving upon near-obsolete products. At Richfields, reverse engineering is made possible by developing insights and information from current manufacturers. This is crucial, especially if you want to have a prototype concept that you want to actualize.

Richfields employs over 20 engineers who are professionals in this field of manufacturing. Even when you don’t yet have a blueprint of the product that you want, they can help you come up with an initial concept and guide you throughout every phase of the manufacturing process.

Injection Mold Manufacturing and Plastic Tooling

From a professional company specializing in custom plastic injection molding in China, Richfields’ main field of expertise is injection molding. At present, more than half of their molds are distributed across the globe in countries such as the USA, Italy, Germany, France, Japan, Brazil, and the US. Any injection molded product that is set for distribution to these locations are able to meet quality assurance checks and any standards for consumer goods, automotive components, household items, electrical components, and many more.

To ensure that all resulting plastic injection molds are free from defects and done without any major issues, Richfields makes use of a program known as mold flow analysis. This is a software that can simulate the process of mold flow in an injection mold machine. This is so that any issues that can be identified during the simulation can be corrected herein especially when the client needs to meet demands on tolerance, complex designs, adjust wall thickness, and reduce common injection mold defects.

Wide Variety of Industries

Richfields serves a wide variety of industries, which is what makes their plastic injection molding process versatile and adaptable. Through a combination of different processes like reverse engineering, mold manufacturing, product simulation and the like, they have been able to manufacture a wide range of components.

Richfields’ clients come from industries like automotive, hygiene products, consumer goods, hardware, sports equipment, household products, toys, electrical housings, bottle caps, decor, computers, and so on. Despite the multitude of industries they provide injection mold services to, they make sure that quality is present each time. There are no compromises on product function and appearance, ensuring that these injected molded products last for a long time without encountering manufacturing faults.

Large Part Injection Molding

Finally, Richfields also specializes in large part injection molding. This is for companies that are in need of large components, whether it be through single-shot, multi-shot, overmolded, or multiple-part plastic assembly processes.

You can find injection molding machines from Richfields that have large platen sizes — from 1700 mm to 350 mm, depending on your requirements. Their injection mold equipment ranges from the 2200 TON Toshiba up until the 100 TON plastic injection molding machine from Taiwan Lian You.

Key Takeaway

Richfields Plastics is the leading provider of custom plastic injection molding in China. This is made possible by employing a number of manufacturing techniques that are all conducted by a highly-skilled and professional team.

In need of custom plastic injection mold manufacturing? Richfields Plastics can the job. Click here to learn more about their services! You may also contact them here for any inquiries as well as, to request for a quotation.