December 7, 2025

Common Injection Molded Products for Consumer Goods

Overview

- Injection molding plays a vital role in producing durable, cost-effective consumer products such as kitchenware, toys, electronics casings, and personal care items.

- Injection molding’s ability to create complex shapes with consistent quality makes it ideal for mass production across various industries.

- Richfields stands out as a reliable partner, combining expertise and quality assurance to deliver precision plastic injection molding solutions.

Great ideas only succeed when they can be manufactured efficiently, consistently, and at scale. For design consultants and product development managers, turning a concept into a tangible product demands a process that balances creativity with practicality. Injection molding provides that bridge, transforming innovative designs into reliable, market-ready goods.

By understanding the common injection molded products for consumer goods, teams can better align design decisions with proven manufacturing capabilities. This method ensures speed in production, uniformity in quality, and cost-effectiveness at high volumes. Keep reading to discover the products that shape today’s consumer markets and why injection molding makes them possible.

Injection-molded kitchenware includes food containers, spatulas, measuring cups, mixing bowls, and ice cube trays. These plastic products combine durability, safety, and lightweight design, making them ideal for daily cooking and food storage.

Manufacturers rely on injection molding to deliver precise, uniform pieces at scale, ensuring consistency in every household essential.

Beverage containers, condiment packaging, and personal care bottles are among the most common molded plastic parts. These lightweight and practical plastic bottles are engineered for safety, efficiency, and everyday use across homes and businesses.

Molding technology guarantees strength, uniformity, and cost-effectiveness, making bottles indispensable in multiple industries.

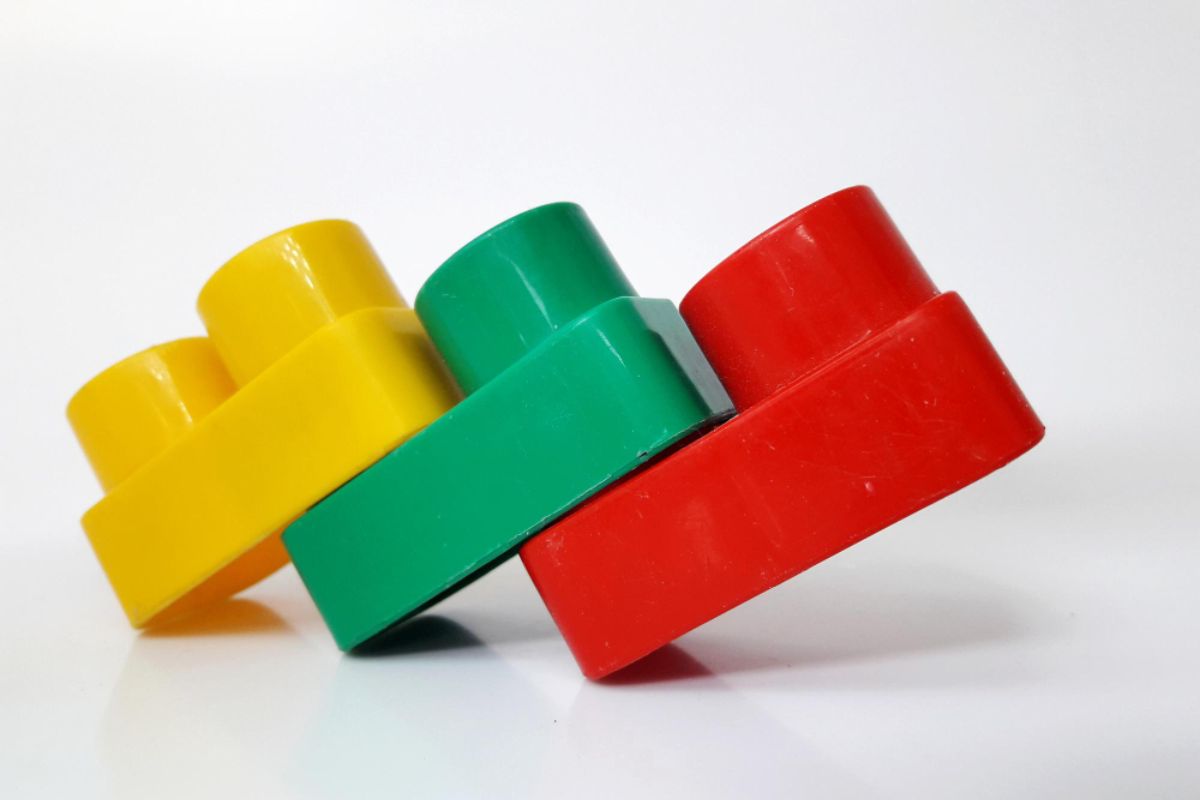

Molded toys such as Legos, puzzles, and action figures demonstrate how durable plastic parts bring creativity to life. Bright colors, safe materials, and accurate dimensions ensure every piece connects smoothly, providing children with long-lasting play value.

Precision molding allows toy manufacturers to produce fun, reliable products trusted by families and educators alike.

Smartphone housings, remote control covers, and appliance casings all depend on injection-molded components for protection and functionality. These plastic parts keep electronics lightweight, insulated, and durable without sacrificing slim, modern designs.

Through molding processes, manufacturers can achieve intricate shapes and seamless fits, which enhance product performance and safety.

Chairs, tables, and storage units highlight how injection-molded furniture balances style with functionality. These molded pieces resist moisture, weather, and daily wear, while offering versatile designs in a range of colors and finishes.

Injection molding ensures that each item is sturdy yet lightweight, making them suitable for both residential and commercial spaces.

Toilet seats made from molded plastics provide comfort, sanitation, and resilience for homes, offices, and public restrooms.

Manufacturers use injection molding to create bulk quantities with consistent shapes, durability, and easy installation. These qualities make molded toilet seats practical, affordable, and accessible across diverse consumer markets.

Injection-molded consumer goods also include personal care essentials like combs, toothbrush holders, and cosmetic containers. These molded plastics are valued for their durability, portability, and hygienic properties. It makes them ideal for home, gym, or travel use.

Consistent molding processes ensure each product meets quality standards while remaining cost-effective.

Injection molding is favored by household product manufacturers because it combines efficiency, consistency, and cost-effectiveness when producing large quantities of everyday items. This process allows for high-volume production of identical products, keeping up with consumer demand while reducing per-unit costs. Its flexibility supports complex designs and intricate details that other manufacturing methods struggle to achieve.

Durable molds ensure that every batch maintains consistent quality and strength, while the wide range of compatible plastics allows for products with different textures, finishes, and performance characteristics. The result is a reliable, scalable method that meets both functional and aesthetic needs for household goods.

Start by assessing the company’s experience with similar products, especially in managing difficult designs or large-scale production. Evaluate their capabilities in mold outline, material handling, and production capacity to guarantee your volume and precision requirements are met.

Additionally, inspect quality control processes, certifications, and client references to verify their credibility. A strong associate should also provide engineering assistance and be flexible enough to cater to design changes or custom specifications.

Finally, consider their communication, logistics, and after-sales support, as these are key to a seamless and on-time manufacturing production procedure.

Richfields is a leading provider of precision plastic injection molding solutions in China, trusted by global brands for both consumer goods and large-scale industrial components. With decades of hands-on experience in design, tooling, and high-volume production, we consistently deliver products that meet the highest standards of quality, durability, and functionality.

Our advanced manufacturing capabilities and rigorous quality control processes ensure every component is reliable, accurate, and production-ready, helping businesses scale efficiently while maintaining performance and consistency.

For common injection molded products for consumer goods, Richfields is a reliable partner, whatever sector you belong to. To understand more of our offerings, do not hesitate to reach out to us today. We’ll gladly accommodate all your queries.