October 3, 2024

Who is the Best China Large Plastic Prototype Maker

Overview

- China has emerged as a premier destination for large plastic prototype manufacturing, attracting global businesses in search of high-quality and cost-effective solutions.

- With advanced technology, extensive expertise, and a commitment to customization, Richfields positions itself as a leader in the industry.

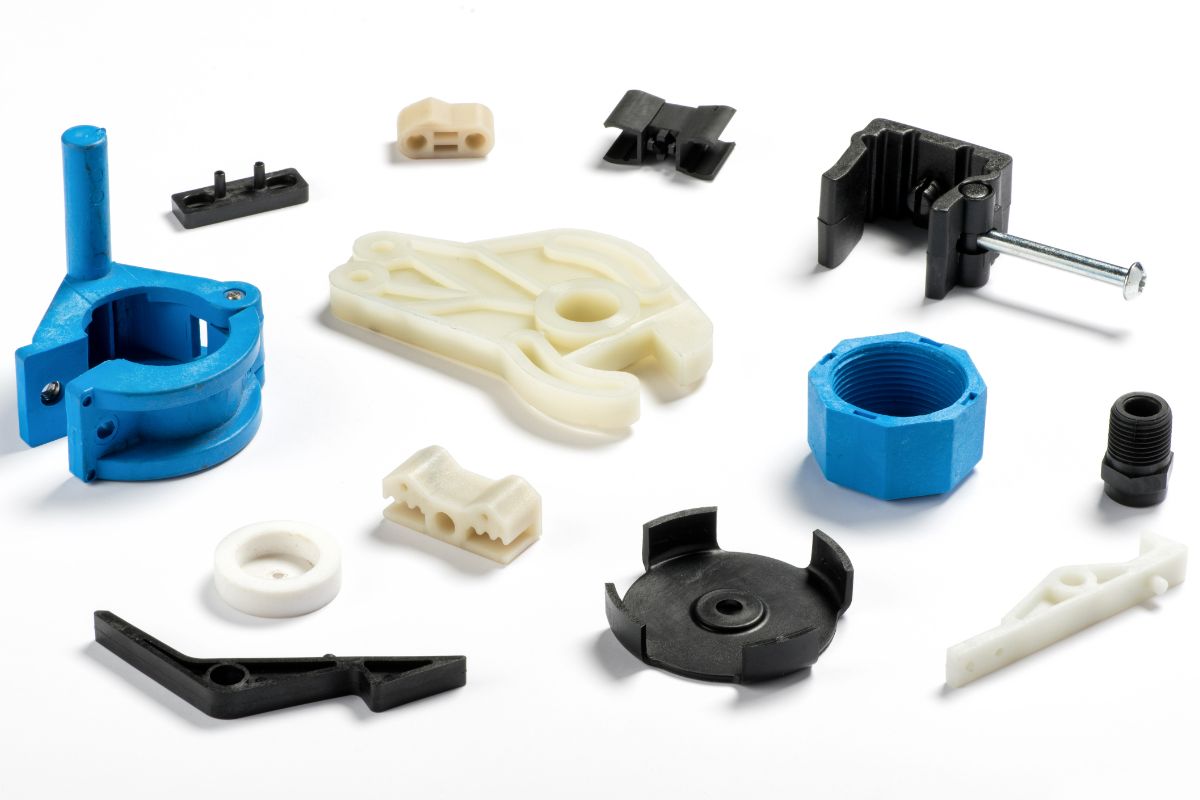

China has established itself as a leading hub for large plastic prototype manufacturing, attracting businesses worldwide seeking high-quality and cost-effective solutions. Large plastic prototypes serve as essential preliminary models, enabling companies to test and validate design concepts before full-scale production. This process allows for the evaluation of functionality, fit, and aesthetic appeal, ensuring the final product meets specifications.

This article will explore the factors to consider when choosing a large plastic prototype, highlighting the strengths and capabilities of Richfields in delivering exceptional China’s prototype large plastic parts and plastic injection molding tailored to diverse client needs.

Richfields Corporation stands out as the best large plastic prototype maker in China, leveraging decades of experience and advanced technology to deliver high-quality solutions for various industries. Our expertise in mass-producing large-size plastic injection molds ensures we can meet the specific demands of clients, whether for automotive components or other large-scale applications.

We utilize state-of-the-art machinery and rigorous quality control processes to guarantee that every prototype meets exact specifications. Our flexibility and cost-competitive offerings make us the go-to partner for businesses seeking reliable and efficient manufacturing solutions for large plastic parts.

When selecting a large plastic prototype maker, it’s essential to evaluate several key factors that can significantly impact the success of your project.

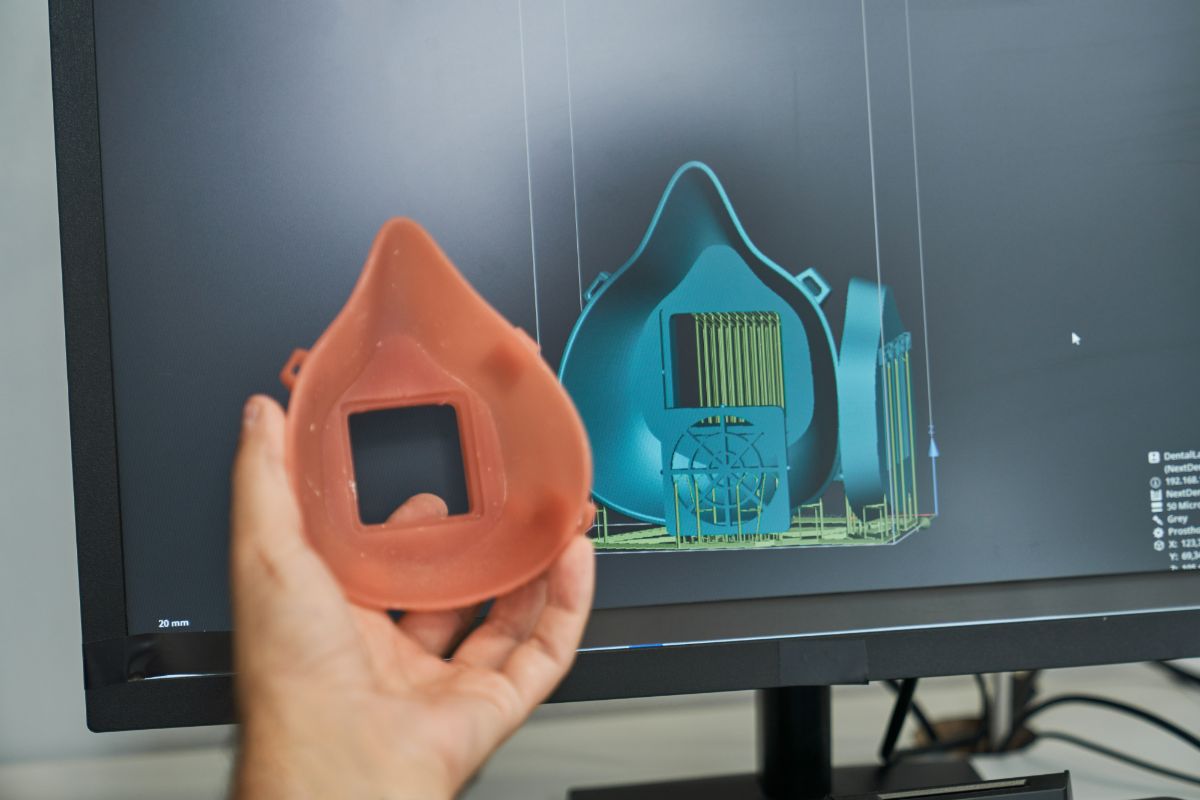

Leading manufacturers utilize state-of-the-art equipment, such as computer numerical control (CNC) machines, 3D printing, and precision injection molding systems. These technologies ensure high accuracy and consistency, allowing for the creation of complex prototypes with intricate designs.

Advanced machinery enhances the efficiency of the production process, reducing lead times and minimizing waste. Modern equipment can also accommodate a wide range of materials, enabling manufacturers to tailor prototypes to specific project requirements.

By investing in the latest technology, a plastic prototype maker can deliver superior-quality products that meet stringent industry standards.

Expertise and experience are important attributes that directly impact the quality of the prototypes produced and the efficiency of the manufacturing process. An experienced manufacturer possesses a deep understanding of advanced molding techniques, material properties, and industry-specific requirements, allowing them to navigate challenges effectively and deliver superior results.

Moreover, an established company brings a wealth of knowledge to the table, having refined its processes through years of practice. This translates into the ability to optimize designs, reduce production timelines, and minimize costs, all critical factors in any industry.

A seasoned provider is also more likely to be familiar with the latest technologies and innovations in plastic manufacturing, ensuring that clients benefit from cutting-edge solutions.

With a focus on precision and quality, an expert in China’s prototype large plastic parts can help businesses bring their ideas to life, fostering collaboration and enhancing product development.

Customization can take many forms, from adapting mold designs to meet complex geometries to selecting materials that enhance performance characteristics. Whether you require precise dimensions for intricate components or need specialized textures and finishes, the right partner can provide the flexibility to accommodate various design parameters.

Additionally, their ability to pivot and adjust production processes in response to evolving project demands is crucial for meeting deadlines and maintaining quality. This adaptability not only streamlines the development process but also ensures that the end product exceeds expectations.

These factors ensure that the final product aligns precisely with your design specifications and functional requirements. A reputable manufacturer like Richfields Corporation understands that each project is unique, offering tailored solutions that cater to specific needs.

In today’s competitive market, being able to prototype and iterate designs quickly can be the difference between success and falling behind. Rapid prototyping allows businesses to test concepts, gather feedback, and make necessary adjustments swiftly, ensuring that products meet market demands and client expectations.

Choosing a manufacturer that prioritizes fast turnaround times means reduced delays in product development. This agility not only speeds up the launch process but also minimizes costs associated with extended production timelines.

Furthermore, a responsive manufacturer can adapt to changes in design specifications, ensuring that any revisions can be implemented without significant disruption.

With the growing demand for precision-engineered components across various industries, it is crucial to partner with a manufacturer that not only meets technical specifications but also understands the unique challenges of rapid prototyping. The right choice will ensure that your product development process is smooth, cost-effective, and aligned with your strategic goals.

If you’re ready to bring your ideas to life with high-quality plastic prototypes, contact us today. With our expertise and dedication to excellence, you can trust us to deliver prototypes that meet your specifications and exceed your expectations.