August 2, 2024

5 Applications of Unscrewing Mold

Overview

- This article delves into different industries that apply unscrewing mold.

- Unscrewing molds offer a versatile and efficient solution for producing products with intricate threaded components.

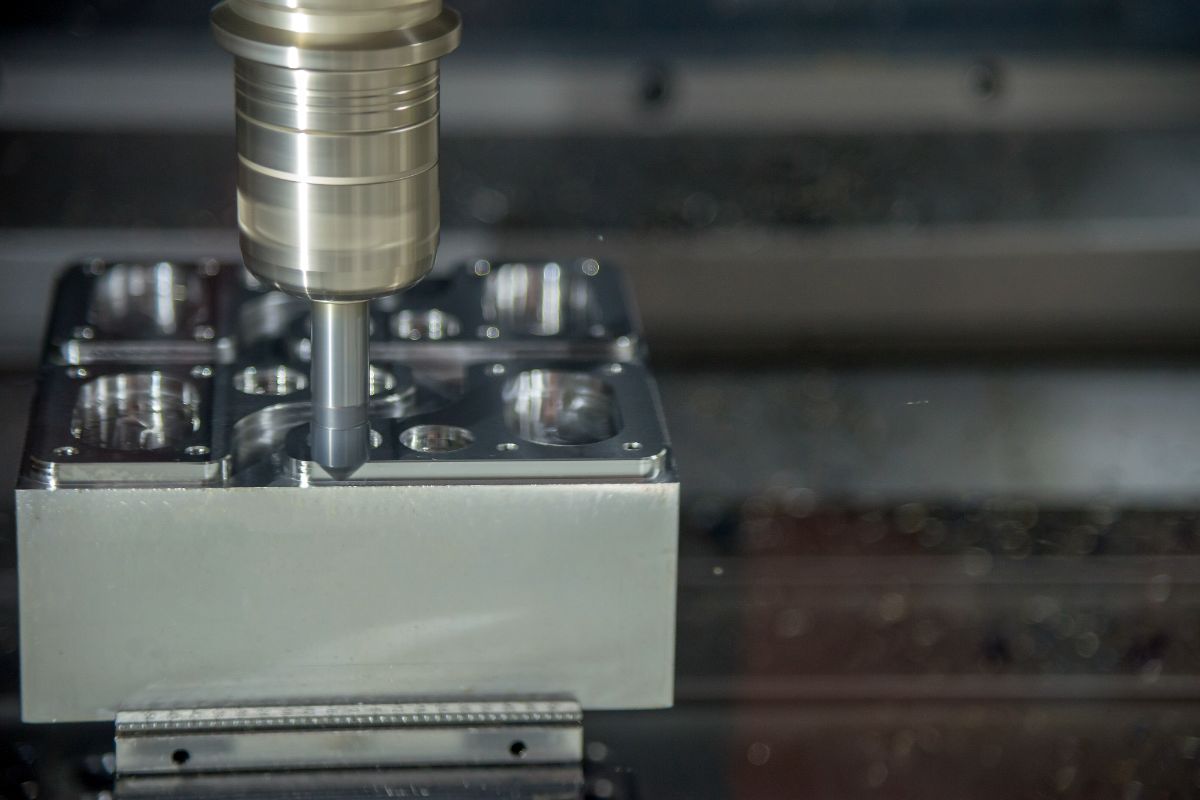

Unscrewing molds are a specialized type of injection molding technology that facilitates the production of components with intricate threading. This unique process involves the movement and rotation of the mold to carefully unscrew parts after they are formed, making it ideal for producing items that cannot be easily removed using standard methods.

In this article, we will explore the different applications of unscrewing mold. We will delve into the specific products and components that benefit from this innovative manufacturing technique.

The automotive industry is a prime example of the application of unscrewing molds. These molds are crucial for producing components with intricate threaded features, such as engine parts like oil and fuel filters, and exterior parts like fuel caps.

The ability to produce threaded components with high accuracy is crucial in automotive manufacturing. These parts require exact fit and functionality to optimize vehicle performance and safety. Unscrewing molds eliminates the need for secondary machining operations, streamlining the production process and reducing costs.

Furthermore, the versatility of this process allows for the creation of a wide range of threaded components with varying shapes and sizes. This adaptability is essential for meeting the diverse design requirements of the automotive industry, ensuring that components meet stringent quality standards.

Unscrewing molds are essential tools in the packaging industry, enabling the production of threaded closures for a wide range of products. These molds ensure precise thread formation, enabling secure and tamper-evident seals for bottles, jars, and containers.

Beyond functionality, it contributes to product aesthetics and user experience. Innovative designs, such as easy-open caps and child-resistant closures, enhance product appeal and convenience.

Reusable containers with threaded closures, produced using this technology, promote eco-friendly practices and reduce plastic waste. This aligns with growing consumer demand for sustainable products and packaging.

In the medical industry, unscrewing molds are specifically designed to create threaded components with exceptional precision, ensuring optimal functionality and patient safety.

For instance, in producing syringes, these molds are employed to manufacture the plunger and barrel with accurate threading. This precise fit is essential for accurate dosage and preventing leaks during use.

Additionally, medical devices like inhalers and diagnostic equipment require threaded housings for secure assembly. This process excels in producing these components with the required precision and sterility.

By producing intricate components in a single step, manufacturers can reduce handling and contamination risks, ensuring the highest quality standards for medical devices.

As one of the basic consumer goods, the cosmetics industry places emphasis on product integrity and consumer satisfaction. Unscrewing molds achieves these objectives by enabling the production of secure and reliable packaging solutions.

These molds are instrumental in creating precision-engineered threaded closures for jars, bottles, and other cosmetic containers. The tight-fitting threads ensure optimal product preservation, shielding delicate formulations from contamination and degradation. This not only extends product shelf life but also guarantees consumers receive skincare items that maintain their original quality and efficacy. This ensures that each container functions as intended, protecting the product and enhancing the consumer experience.

Unscrewing molds excel at creating detailed and intricate designs, including parts with internal or external threads. This capability is essential for products that cannot be easily removed using standard knock-off methods, such as bottle caps, medical supplies, and automotive components. The ability to produce these complex shapes in a single operation enhances design flexibility and innovation.

This technology accommodates a broad spectrum of plastic materials, providing manufacturers with flexibility in material selection to optimize product performance and durability. From polypropylene to high-density polyethylene, unscrewing molds deliver consistent results, ensuring product quality and reliability.

While the initial investment in unscrewing molds may be higher, the long-term savings from reduced labor, fewer defects, and lower material waste make them a cost-effective solution for high-volume manufacturing. The efficiency gained from using these molds can significantly lower overall production costs.

The applications of unscrewing molds improve efficiency and contribute to the overall quality of products, benefiting consumers by providing reliable and well-designed items. As industries continue to evolve and demand for innovative solutions grows, this technology will remain an essential tool in any manufacturing market, driving advancements and ensuring that products meet the highest standards of quality and functionality.

If you’re looking for a plastic mold manufacturer in China, partner with us at Richfields Corporation. Beyond providing high-quality plastic injection molding services we also offer a comprehensive range of products, for different industries. Our extensive mold inventory, encompassing runner molds and precision plastics, demonstrates our commitment to delivering versatile solutions to meet your diverse needs. Contact us today to discuss your project.