What are the different uses of plastic overmolding in the U.S.A.?

- Automotive products

- Electronic products

- Medical devices

- Industrial equipment

- Kitchen components

Overview

Plastic overmolding has transformed product design and functionality in a diverse range of industries throughout the United States. Its applications span automotive components, electronic devices, medical equipment, industrial machinery, and kitchen components, unleashing an array of advantages. It enhances grip and ergonomics, optimizes user interfaces, reinforces structural integrity, ensures precision and safety in medical devices, improves durability in industrial equipment, and prioritizes food safety in kitchen components. This versatile manufacturing technique remains pivotal in delivering superior, durable, and reliable products across the United States.

Plastic overmolding is a versatile manufacturing technique that finds extensive applications across industries in the United States. From automotive components to electronic devices and medical equipment, this manufacturing process has revolutionized product design and functionality.

In this article, we will delve into the specific applications of plastic overmolding in the U.S.A., highlighting its invaluable contributions to various sectors and the benefits it offers in creating superior, reliable, and ergonomically designed products.

Automotive Products

In the U.S.A., the automotive industry focuses on providing innovative, competitive automotive products. These products are often made from plastic over-molding and undergo a specialized manufacturing process that combines different plastic materials to create functional and durable components.

The process typically involves molding a rigid plastic substrate, usually made from materials, such as polypropylene or nylon, which forms the main structural component of the automotive part. This substrate is then placed into a mold cavity, and a second molten plastic material, often a rubberized or soft-touch material like TPE (thermoplastic elastomer), is injected over and around the substrate to create the final over-molded part.

As a result, it enhanced the grip, comfort, and ergonomic features of automotive components, such as steering wheels, gear shift knobs, armrests, instrument panel trim, and door handles.

Electronic Products

![]()

In 2023, an average American is projected to own 2.91 consumer electronics devices, showcasing the wide adoption and utilization of electronic gadgets in their daily lives. Among the factors driving the transformation of electronic products, plastic over-molding plays a significant role.

It enables the seamless integration of buttons, control panels, and switches directly into the design of electronic products, leading to an enhanced user interface. Devices like smartphones, remote controls, keypads, and game controllers benefit from this feature, which provides users with intuitive interfaces and effortless control.

It also reinforces the structural integrity of electronic products, offering substantial strength and impact resistance.

Medical Devices

Plastic overmolding plays a pivotal role in the creation of medical products that meet the stringent requirements of healthcare professionals. By integrating overmolding techniques, the American healthcare industry benefits from enhanced precision, safety, and efficiency.

It also brings additional functionalities to medical devices. It enables the incorporation of features like improved grip, soft-touch surfaces, and superior sealing capabilities, thus preventing leakage and contamination. Furthermore, medical devices can be designed using materials that exhibit desirable properties, such as chemical resistance, biocompatibility, and stability.

This ensures that medical professionals have access to tools that adhere to strict industry standards, promoting optimal patient care and safety.

Industrial Equipment

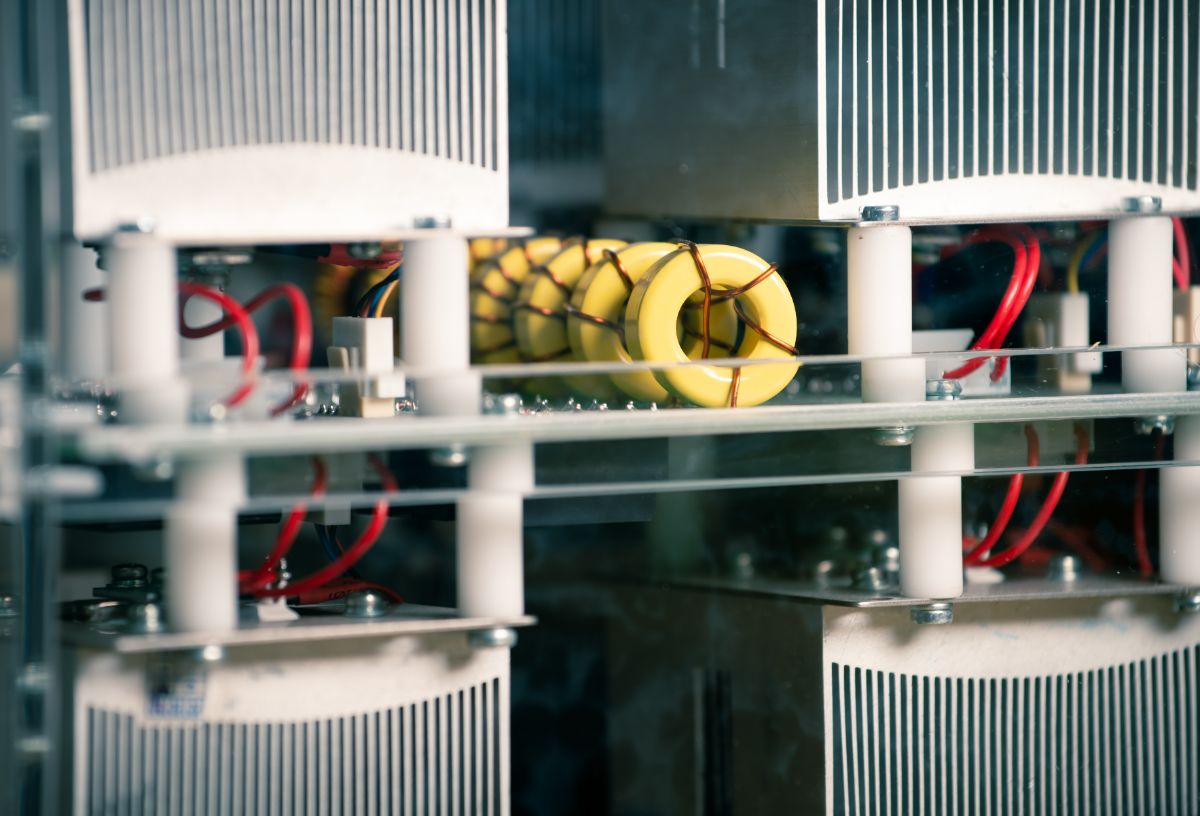

Plastic overmolding enhances the durability and reliability of industrial equipment. For instance, encapsulating sensitive components, such as connectors, switches, or electronic circuits, with a protective plastic layer provides an additional barrier against environmental factors, including moisture, dust, and vibrations. This improves the overall robustness and longevity of the equipment, reducing the risk of failures or malfunctions.

It also allows for the integration of multiple materials with different properties into a single equipment component. This opens up possibilities for enhanced functionality, such as combining rigid and flexible materials to achieve desired characteristics like strength, flexibility, or shock absorption.

Kitchen Components

Achieving food safety is a top priority when using plastics to produce kitchen components, such as kitchen utensils, food containers, cutting boards, and more. To meet this crucial objective, manufacturers rely on the critical technique of over-molding in the manufacturing process of these components, ensuring compliance with rigorous food safety standards.

By embracing overmolding techniques in the production of kitchen components, manufacturers deliver products that prioritize food safety, offer superior functionality, provide optimal comfort, and present an enjoyable cooking experience for consumers.

Key Takeaway

These applications of plastic overmolding enable companies in the U.S.A. to create innovative and functional products across various industries. From automotive and electronics to medical and kitchen components, this process enhances design flexibility, improves durability, and increases safety, boosting the satisfaction of consumers.

Richfields Corporation, a China-based molding company, provides plastic overmolding services in the U.S.A. Through collaborative partnerships, we manufacture plastic products for our clients and ensure timely delivery to their desired locations. For inquiries or further information, please feel free to contact us today!