January 18, 2026

Tips for Successful Customized Large Injection Molding Projects

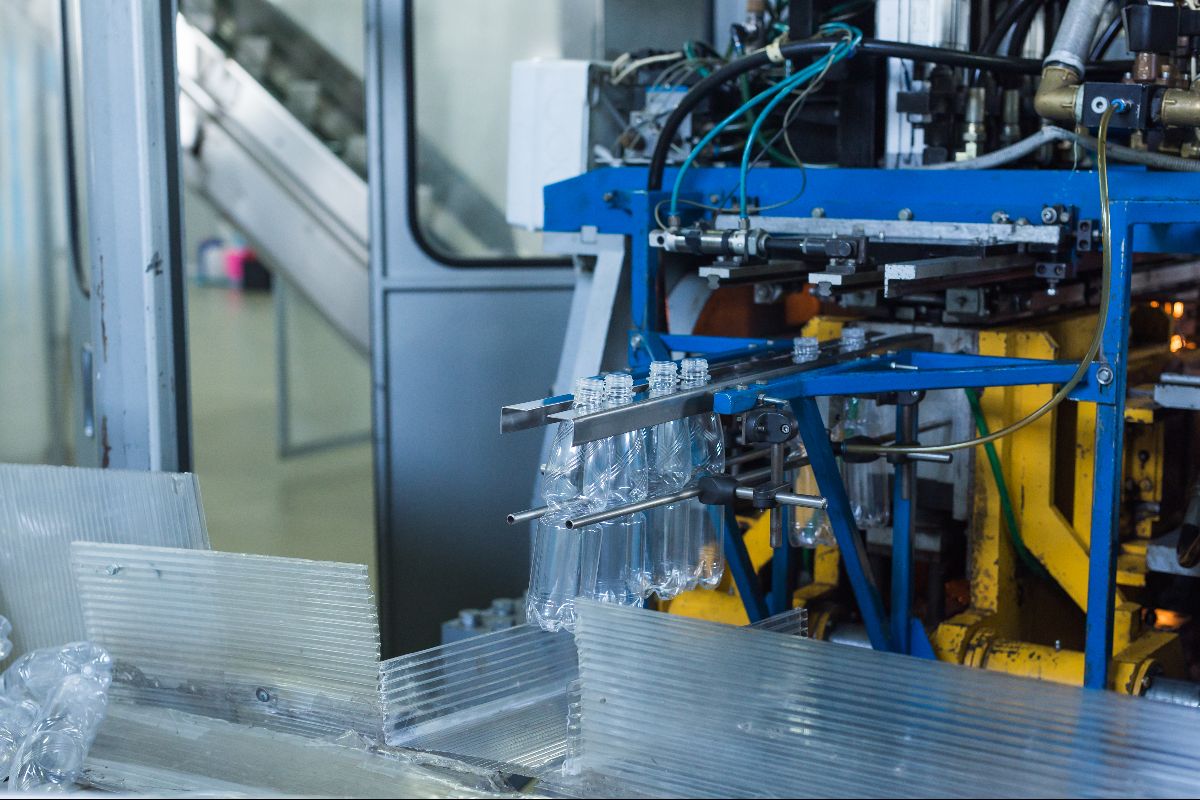

Overview

- Successful customized large injection molding hinges on optimizing every detail, from mold design to quality control.

- Early collaboration with a proactive partner ensures manufacturability and smooth production.

- Richfields Corporation stands out with decades of expertise, advanced machinery, and comprehensive services that guarantee precision, efficiency, and high-quality molded components for diverse industries.

In any complex molding operation, even the smallest inefficiency can ripple into primary setbacks. From inconsistent mold temperatures to uneven material flow, small missteps may result in production delays, wasted resources, or quality defects.

That’s why success doesn’t just rely on technical expertise. It also depends on perfecting every detail of the procedure.

In this article, we’ll give you tips for successful customized large injection molding projects, helping companies in the USA, as well as engineers and design consultants, optimize their operations and maintain strict quality control from start to finish.

Successful large injection molding starts with designs optimized for production. By accounting for manufacturing constraints early, you reduce costly revisions, speed up timelines, and ensure your vision translates accurately into the final product.

Engaging a skilled manufacturing partner during the design phase allows for expert guidance on material selection, mold feasibility, and part geometry.

Richfields Corporation, a leading large plastic injection molding company in China, combines decades of experience with advanced machinery—ranging from 650 to 2,200 tons of clamping force—and sophisticated techniques like gas-assist molding for large or thin components. From mold creation to full-scale production, we provide end-to-end support, maintaining open communication and flexibility while keeping projects on schedule and within budget.

At Richfields, we optimize your designs for efficiency, quality, and manufacturability, preventing costly revisions before production begins. Here’s how we do it:

During production, designs must meet the highest quality standards. Close monitoring of the injection molding process, systematic inspection of components, and verification that each part meets exact specifications are critical steps.

Trapped air and gases must escape during molding to prevent defects such as burn marks or incomplete fills. Correctly located, sized, and angled vents promote smooth material flow and consistent part quality.

Proper cooling prevents uneven shrinkage, warping, and internal stresses. Strategically designed cooling channels ensure heat is absorbed and dissipated evenly across all molded parts.

Continuous tracking and evaluation of the molding process help detect defects early. Detailed process records and inspections minimize waste and ensure consistent, high-quality outputs.

Trial production cycles identify potential issues, verify part consistency, and allow adjustments before full-scale manufacturing. This step reduces errors and ensures efficient production.

Tasks such as trimming, finishing, painting, or assembly should be planned and coordinated ahead of time. Proper post-processing ensures a smooth workflow and consistent final product quality.

Ensuring that all parts fit and function together correctly is essential for delivering products that meet expectations. Proper post-production management preserves product integrity and supports reliable client experiences.

Effective post-production includes technical support, troubleshooting, and maintenance to keep molds and equipment operational. Clear communication channels, scheduled check-ins, and ready spare parts help minimize downtime and address issues quickly.

A proactive post-production approach improves product performance while building confidence and long-term collaboration with clients.

For tips for successful customized large injection molding projects, it is crucial to focus on detailed design optimization, selecting the right materials, and maintaining strict quality control throughout production. Collaborating early with your molding partner helps avoid costly revisions and ensures smooth processes.

Richfields Corporation excels in guiding clients through every stage of successful customized large injection molding projects, combining decades of expertise, advanced machinery, and full-cycle services. From design for manufacturability to precise production, quality control, and post-production support, we ensure efficiency, consistency, and top-tier results.

Reach out today to discover how our end-to-end solutions can help streamline your projects, reduce risks, and deliver high-quality custom molded products tailored to your specifications.