October 5, 2025

Common Mistakes to Avoid When Sourcing Large Plastic Parts

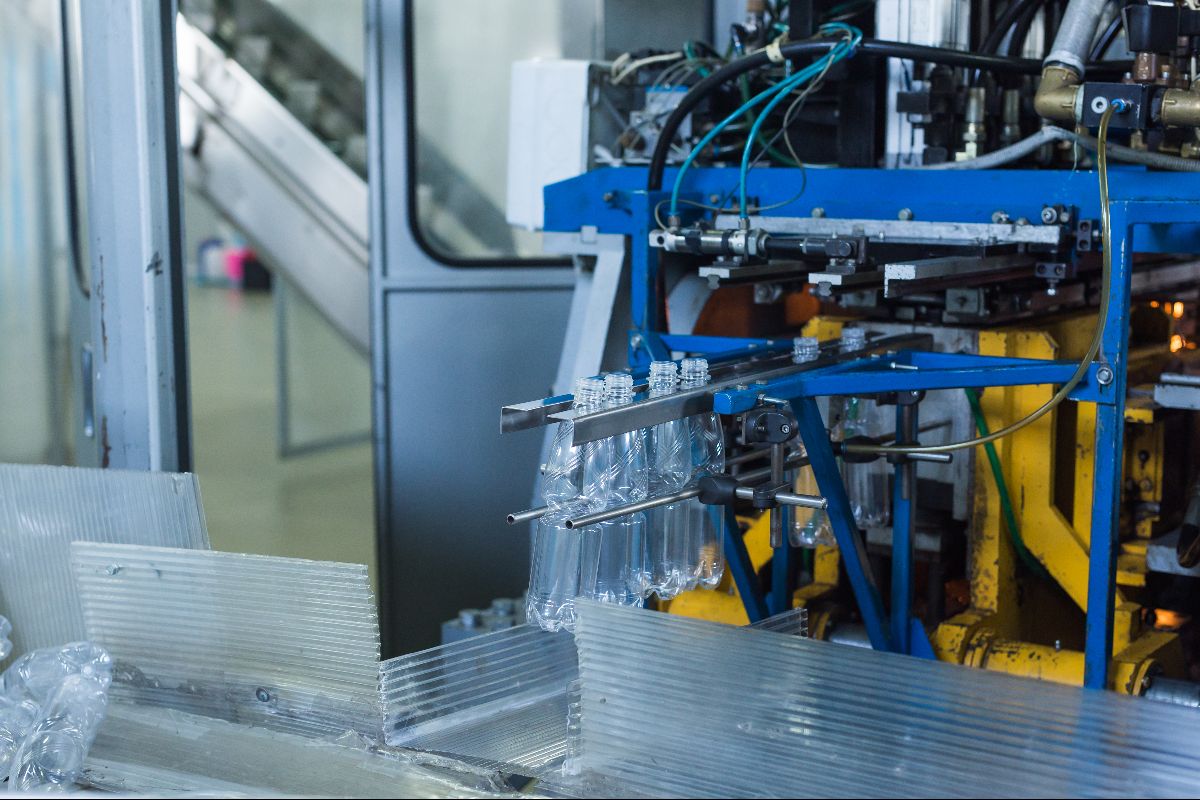

Overview

- When launching products relying on large plastic components, avoiding sourcing mistakes is critical to maintain quality and timelines.

- Common errors include ignoring supplier expertise, material suitability, mold quality, lead times, prototype testing, and logistics planning.

- Richfields stands out as a reliable partner, offering full-service plastic injection molding with precision and efficiency to ensure timely delivery and excellent product standards.

Sourcing large plastic parts isn’t as straightforward as it may seem. From tooling requirements to material selection and shipping logistics, there are several unique challenges that buyers need to anticipate.

Without careful planning, these complexities can lead to delays, budget overruns, or compromised product quality. That’s why it’s crucial to understand the common mistakes to avoid when sourcing large plastic parts, especially if you’re working on high-volume or large-scale projects. By being aware of these pitfalls ahead of time, you can protect your investment and ensure a smoother production process. With the right supplier, these hurdles don’t have to stand in the way of your success.

Richfields has the proven experience to guide companies through these challenges, offering the expertise and reliability needed to deliver large plastic parts efficiently and cost-effectively. Keep reading to learn more!

Selecting a good manufacturing partner goes beyond just comparing prices and lead times. It needs a clear understanding of whether they have the right technology and expertise to manage the size, intricacy, and material requirements of your components.

Failing to evaluate these capabilities early can lead to late production, compromised quality, or expensive redesigns.

A thorough assessment, such as reviewing past projects, checking facilities, and discussing technical procedures, helps guarantee the distributor can meet your exact specifications from beginning to end.

Wrong material for huge plastic elements may result in issues like warping, cracking, or premature wear. Each application calls for particular properties like strength, flexibility, heat resistance, or chemical tolerance to perform reliably in real-world situations.

Overlooking this match between product and purpose can cause performance failures and maximized upkeep bills.

That’s why collaborating closely with engineers or material experts ensures you opt for the great plastic type that meets functional and environmental needs.

A poorly made mold can sacrifice the precision, finish, and structural integrity of big plastic components. Accuracy in mold layout and fabrication is vital to ensure every part is according to the exact specifications and maintains continuity as the production runs.

Neglecting mold quality leads to defects, higher rejection rates, and costly rework. Therein, associating with experienced mold makers and investing in top-grade tooling can significantly enhance product performance and manufacturing effectiveness.

Lead time refers to the duration between placing an order and receiving the finished product, encompassing mold design, manufacturing, material sourcing, assembly, and quality checks. When it comes to large plastic parts, these stages are often more time-intensive than with smaller components due to longer mold fabrication, material procurement, and testing requirements.

Underestimating these timelines can disrupt production schedules, delay product launches, and strain budgets. Rushing the process also increases the risk of incomplete designs or missed quality inspections. Careful planning with your supplier ensures realistic deadlines, smoother workflows, and reliable project execution.

Prototype testing involves creating and reviewing a sample part before moving into full production. This step is especially critical for large plastic components. This process helps identify potential design flaws, fit issues, or performance concerns early on, reducing the risk of costly mistakes.

Skipping prototype testing may result in entire production runs with defects, leading to wasted materials, expensive rework, and project delays. Investing in this stage ensures that the final product is accurate, functional, and fully compliant with quality standards, ultimately safeguarding both timelines and budgets.

Logistics ensures that large plastic parts are delivered safely, cost-effectively, and on time. Due to their size and weight, these components often require custom packaging solutions, oversized freight arrangements, and specialized handling throughout the supply chain.

Without planning these details early in the production process, companies may encounter delays, unexpected surcharges, or even damage to the parts during transit. Factors such as international shipping regulations, customs clearance, and storage conditions also need to be considered well in advance. Proactive logistics planning not only safeguards product integrity but also helps manage costs, streamline delivery schedules, and ensure projects stay on track.

Richfields is a trustworthy plastic injection molding company in China that serves global clients with exactness, efficiency, and constant quality. We specialize in creating and supplying large plastic parts with the highest manufacturing standards, backed by complete services from design to delivery.

With our expertise, you can be confident that your products will arrive timely and in excellent condition—ready for utilization or distribution.

Addressing the common mistakes to avoid when sourcing large plastic parts can save your business significant time, money, and assets. By meticulously analyzing manufacturers, planning, and considering all production factors, you can ensure a more seamless manufacturing method and better-quality output.

Richfields is a dependable plastic injection molding company, distributing in China and foreign countries like the USA and Europe. We can help you meet your demands with precision and adequacy. Reach out to us today to discuss your project needs.