September 10, 2025

6 US Industries That Benefit From Injection Molding Services in 2025

Overview

- Injection molding is shaping a range of U.S. industries in 2025, from automotive to consumer electronics and healthcare, by supporting high-volume, precise, and cost-effective plastic part production.

- The role of injection molding grows as sectors demand lighter materials and advanced components to stay competitive.

Richfields stands out as a trusted partner for delivering scalable, quality injection molding solutions to evolving markets.

Many sectors in the United States are now racing to keep up with ever-changing market needs, tighter policies, and rising production expenses. With the climbing demand for efficiency and accuracy, businesses are looking for manufacturing procedures that can deliver rapid and quality.

Injection molding, therein, has become a go-to solution, helping them streamline plastic supply without compromising performance.

In this article, we’ll give you up-to-date information about the US industries that benefit from molding services in 2025, as its impact is more visible than ever.

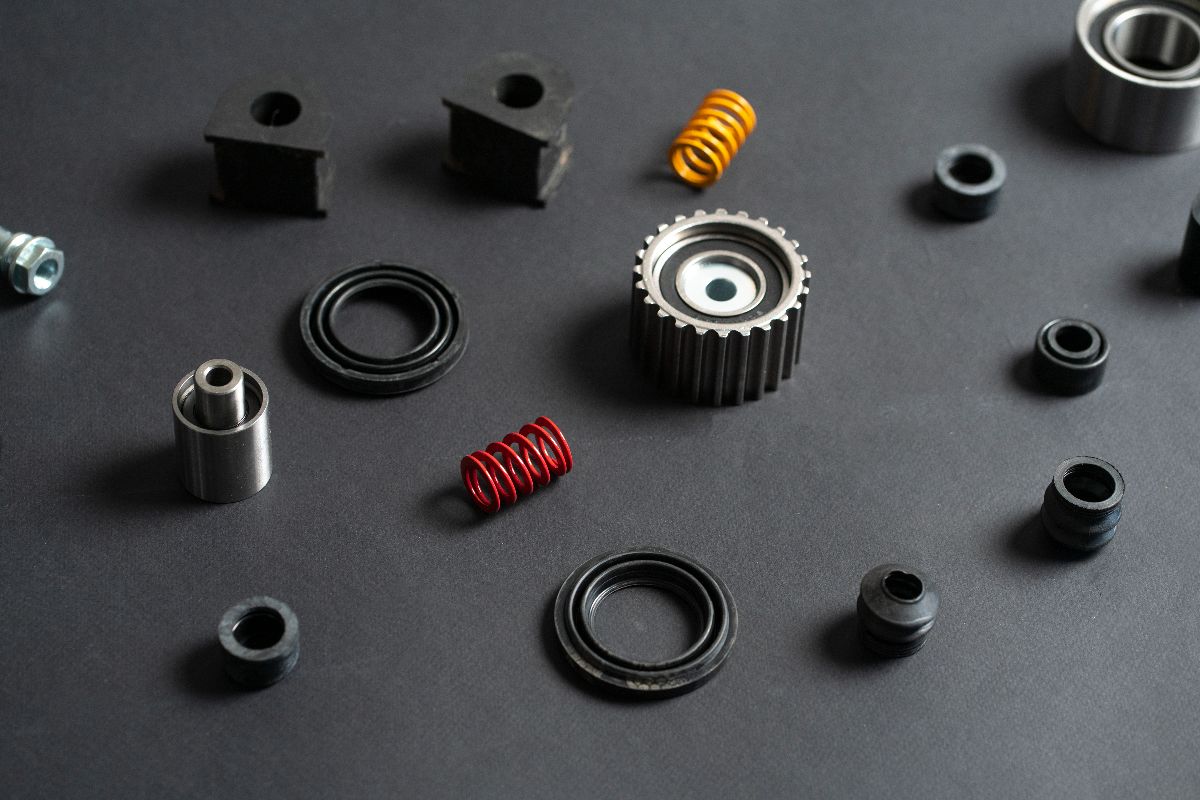

Lightweight products, enhanced fuel efficiency, and lower production fees are driving major shifts in how vehicles are made. Injection molding supports these goals by enabling the mass production of durable yet light plastic parts for interiors, engine bays, and even structural elements.

Automakers depend on this method for its ability to manufacture intricate shapes with tight tolerances, improving design flexibility and safety. With electric vehicles (EVs) becoming more mainstream in 2025, the demand for custom-molded components, such as battery casings and charging pieces, continues to grow rapidly.

Precision and hygiene are crucial in creating tools and equipment used in hospitals, clinics, and laboratories. With injection molding, manufacturing pharmaceuticals like sterile, single-use products like syringes, IV components, and surgical instruments with consistent quality is not impossible.

This high level of demand for personalized care and advanced medical devices in 2025 further boosts the industry’s reliance on this technique. It allows for large-volume production while meeting stringent Food and Drug Administration (FDA) guidelines and maintaining tight tolerances important for patient safety.

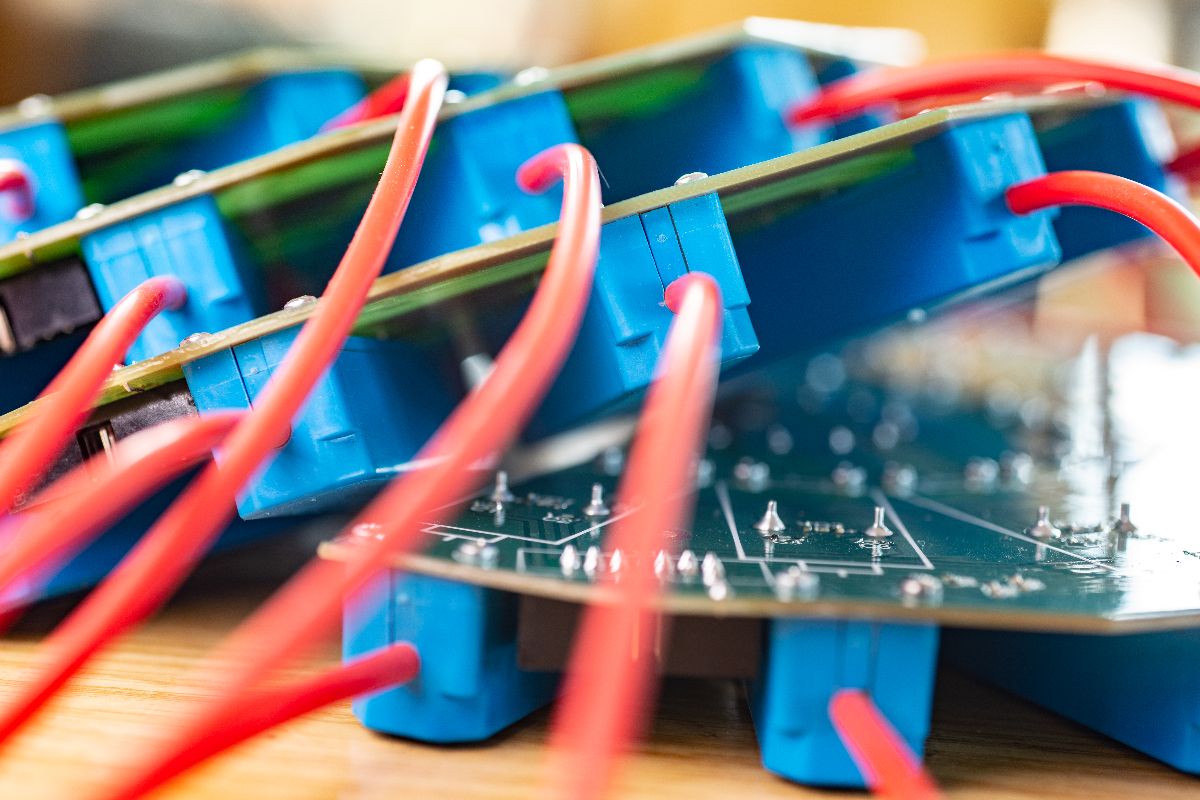

Design flexibility and adequacy are crucial in creating the compact, intricate components found in consumer electronics. Injection molding meets this need by making high-precision housings, connectors, and internal parts used in smartphones, laptops, wearables, and other devices.

As technology evolves in 2025, suppliers seek quicker, scalable solutions to keep up with innovation and market movements. This method helps extensive production while maintaining quality, supporting companies in providing sleek and dependable gadgets to tech-savvy customers.

The food and packaging sector continues to demand durable, safe, and attainable plastic solutions to meet increasing consumption and sustainability standards. Injection molding plays an important role in producing containers, caps, trays, and utensils that are light, uniform, and compliant with food safety measures.

In the current year, the call for hygienic, tamper-proof, and eco-friendly packaging will drive more brands to depend on this practice. Its ability to provide high-volume outputs with low material waste makes it ideal for large-scale packaging operations.

Innovations in aerospace engineering increasingly depend on light, durable products that can be made with precision. Injection molding supports these needs by enabling the production of complex components like interior panels, wiring enclosures, and ventilation parts with exactness and efficiency.

This 2025, the requirement for fuel-efficient layouts and scalable supply solutions continues to emerge. This process helps achieve those objectives by allowing large-volume production to adhere to the right regulations.

Plastic remains a foundational material in distributing parts for home appliances and equipment because of its strength, moldability, and affordability. Injection molding allows suppliers to create accurate, constant elements like outer casings, control panels, and functional components at scale.

With the increasing demand for reliable appliances as the year goes on, this process supports more immediate production while maintaining quality. Its flexibility in design and output makes it indispensable for meeting market expectations.

Richfields Corporation delivers top-tier injection molding services in China that align with the demands of distinct US industries, including those in Europe. With modern machinery, the right tooling, and decades of expertise, we help businesses produce consistent, high-volume plastic parts effectively.

Our high commitment to quality and scalability makes us a credible partner in today’s fast-paced manufacturing scenes.

Understanding how US industries benefit from injection molding services in 2025 gives brands a competitive edge in terms of efficiency, product continuity, and scalability. As sectors like automotive, medical, electronics, packaging, and aerospace evolve, the call for high-precision, cost-efficient plastic parts will only grow stronger.

Richfields delivers contemporary injection molding services aligned with the variation of needs of today’s fields. If you’re looking to elevate your production techniques with trusted and scalable plastic manufacturing solutions, reach out to our passionate team to get started.