How do you find a plastic injection molding company in China?

- Clearly define your project requirements

- Seek recommendations

- Look for companies that hold relevant certifications

- Evaluate manufacturing capabilities

- Request quotes and samples

Overview

- This guide equips businesses with essential strategies for selecting the ideal plastic injection molding partner in China.

- From meticulously defining project requirements and seeking reliable recommendations to evaluating manufacturing capabilities and requesting quotes and samples, each step ensures informed decision-making.

- Highlighting the significance of certifications and manufacturing expertise, it empowers businesses to secure high-quality, cost-effective molding solutions that meet stringent technical standards and align with budgetary considerations.

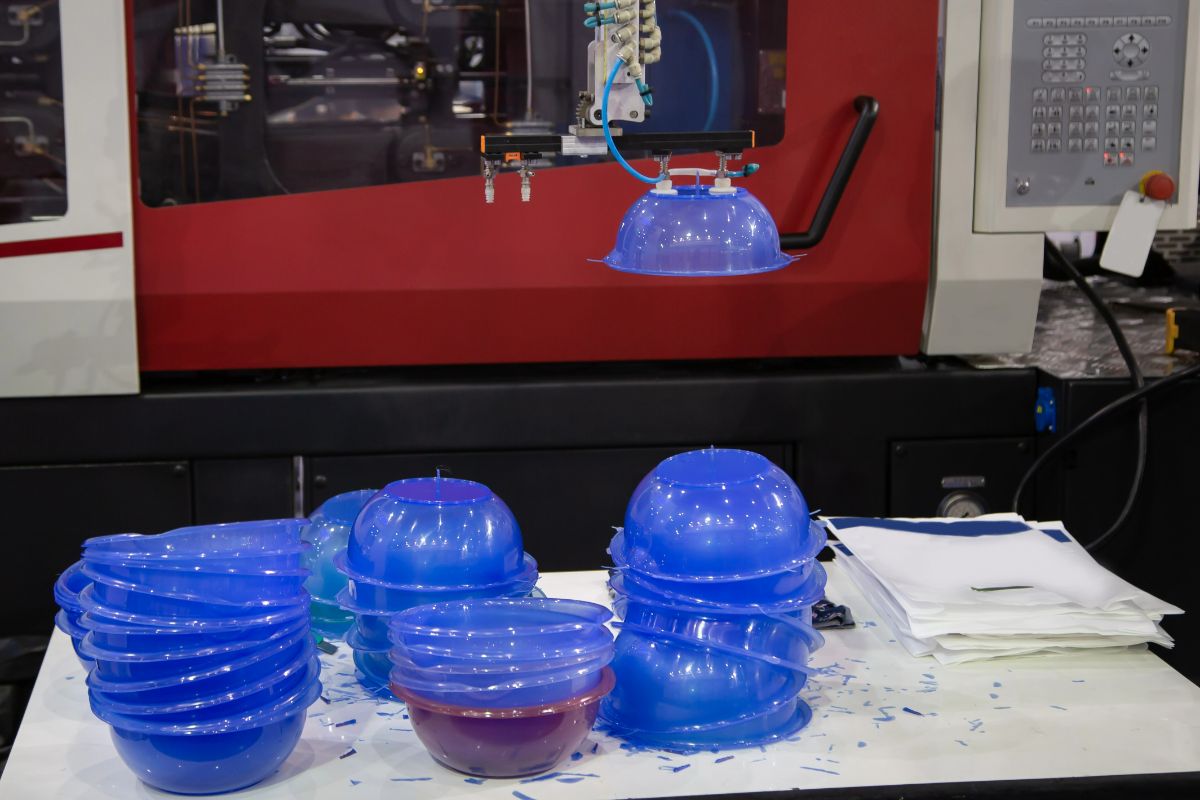

Finding the right plastic injection molding is crucial for businesses looking to leverage cost-effective manufacturing without compromising on quality. With China being a global leader in injection molding, the options are abundant but vary widely in capabilities, expertise, and reliability.

In this guide, we’ll explore how to find plastic molding in China. You’ll be equipped with the insights needed to make an informed decision. Read on to learn more.

Clearly Define Your Project Requirements

You must define your project requirements for a successful collaboration. Start by detailing your product design and specifications, including 3D CAD models, technical drawings, and functional requirements, to provide a clear vision of what you need.

Next, identify the type of plastic material required, considering its durability, flexibility, and heat resistance, and specify any material properties necessary for your product. Additionally, estimate the initial order quantity and potential future production volumes to give the molding company an idea of the scale of your project.

Finally, outline a clear production outline to ensure both parties are aligned on delivery expectations. This helps them assess their ability to meet your needs accurately and deliver a successful product.

Seek Recommendations

Recommendations from trusted sources offer peace of mind, knowing someone had a positive experience with a company you’re eyeing for. This instills confidence in your choice and helps you avoid unreliable or inexperienced companies.

To find these valuable recommendations, search online communities and forums dedicated to the manufacturing industry. These platforms provide opportunities to connect with others who have firsthand experience with molding companies.

Don’t hesitate to inquire about the following:

- Quality of the product

- Reliability and timeliness

- Communication

- Technical expertise

- Pricing

- Post-production support

These inquiries help mitigate risks, ensure satisfaction, and establish confidence in choosing the right partner for your molding needs.

Look for Companies that Hold Relevant Certifications

Certifications are a form of independent verification, signaling a company’s commitment to quality control and adherence to industry standards. These also demonstrate their dedication to professionalism, fostering trust and confidence in their capabilities.

Richfields Corporation exemplifies this. As an ISO-certified plastic injection molding company, we possess extensive experience in various molding fields. Our expertise and capabilities allow us to not only create complex and high-quality products but also perform a variety of secondary and finishing operations, all under one roof, streamlining your project experience.

Evaluate Manufacturing Capabilities

Evaluating the manufacturing capabilities of a plastic molding company ensures they have the technical expertise, equipment, and capacity to meet your specific project requirements. This evaluation helps determine if the company can handle the size, complexity, and volume of your production needs effectively.

It also provides insights into their quality control measures, production efficiency, and ability to adapt to changes or customizations. Assessing these guarantees that your chosen company can deliver high-quality, reliable plastic parts or products that meet your expectations and project timelines.

Request Quotes and Samples

Requesting quotes and samples from plastic molding companies is essential. It allows you to compare pricing and evaluate cost-effectiveness, ensuring that the manufacturing costs align with your budget constraints. It also provides a firsthand look at their workmanship and quality standards, helping you assess if their output meets your expectations and specifications.

Moreover, requesting quotes helps clarify the full scope of services included, such as tooling costs, production volumes, and any additional fees. This transparency aids in avoiding unexpected expenses and ensures you can make an informed decision based on both financial and quality considerations.

This empowers you to select a plastic molding company that not only meets your technical requirements but also fits within your financial parameters while delivering the desired level of quality.

Key Takeaway

When exploring the process of how to find plastic injection molding companies in China, remember, that finding the right partner is an investment in your project’s success. By taking a proactive and informed approach, you’ll be well-positioned to secure a reliable plastic injection molding company in China that delivers high-quality products, on time, and within budget.

Finding the perfect partner for your plastic injection molding project is crucial to achieving success. Richfields Corporation, with over 20 years of experience and a proven track record across various industries, offers the expertise and capabilities you need. We understand the importance of tight tolerances, consistent production, and delivering high-quality results. Contact us today and let us be your trusted partner.