Benefits of Gas Assist Injection Molding in China

There are numerous benefits to using Gas Assist Injection Molding, making it a popular choice for plastic manufacturing in China and beyond. These include, but are not limited to:

- Better Part Quality: The process produces parts with better dimensional accuracy and less warping, resulting in high-quality components that meet strict design and performance standards.

- Faster Mold Production Cycle Time: Gas assist injection molding also significantly speeds up the cycle times because the gas helps push the molten plastic through the mold more efficiently—which means manufacturers can achieve higher output in less time.

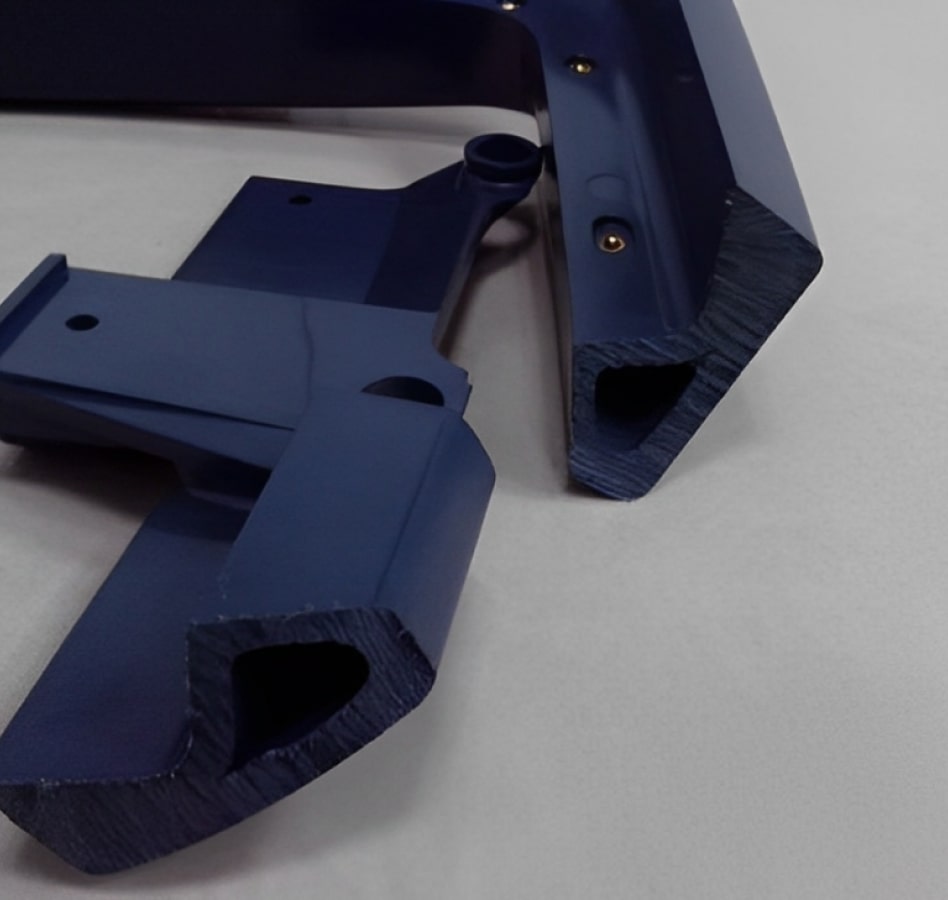

- Improved Surface Texture: This process also produces smoother and more aesthetically pleasing finishes without the need for extra post-processing.

- Reduced Usage of Plastic Materials: By creating hollow sections within parts, this method reduces the amount of plastic material used, leading to lighter products and significant material savings.

- Savings on Expenses: With the material savings through the reduced usage of plastic materials, they translate into lower production costs, making the process both cost-effective and environmentally friendly.