High-Quality Plastic Injection Molding Products for Every Industry

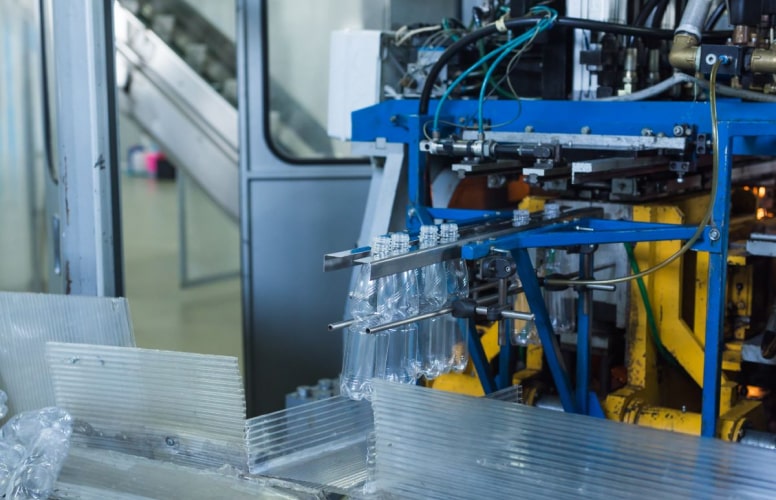

Plastic injection molding is a proven manufacturing process used to produce high-quality plastic components at scale. By injecting molten plastic into precisely designed molds, manufacturers can achieve consistent, dimensionally accurate plastic injection molding products built for strength, durability, and long-term performance.

This technique offers a cost-effective and efficient way to create custom parts for industries ranging from automotive and electronics to consumer goods and logistics. At Richfields, we specialize in delivering high-performance plastic components that meet strict functional and aesthetic standards.