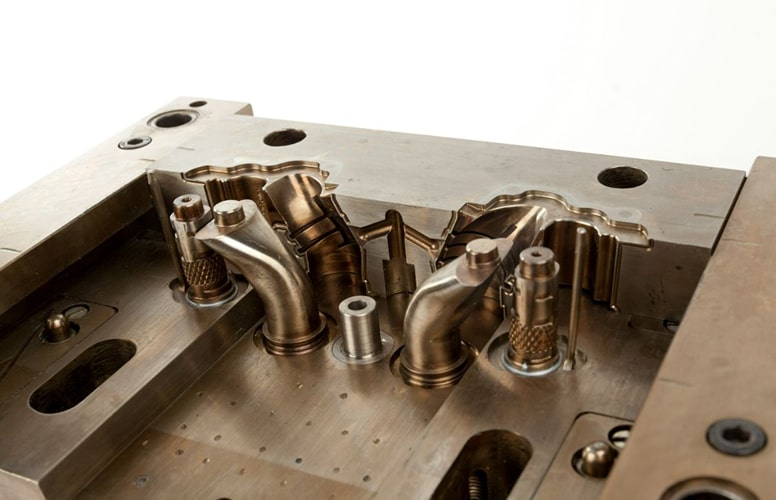

Quality-Driven Manufacturing with Richfields' Injection Molding in China

From everyday items to custom prototypes, plastic has become a popular material for various products. It is a versatile material and satisfies the specific needs across industries through injection molding.

Richfields Corporation, a world-class company for injection molding in China, is your partner. We can export molds to the U.S.A. and other countries. If you’re looking for a world-class plastic manufacturer, you’ve found the right place here at Richfields!