Plastic Tool, Mold Manufacturing and Plastic Injection Molding

Plastic Tool and Mold Manufacturing, Plastic Injection Molding, and Secondary Process (Pad Printing).

Global housewares company selling bakeware, cookware, cutlery, gadgets, and tools originally from the US.

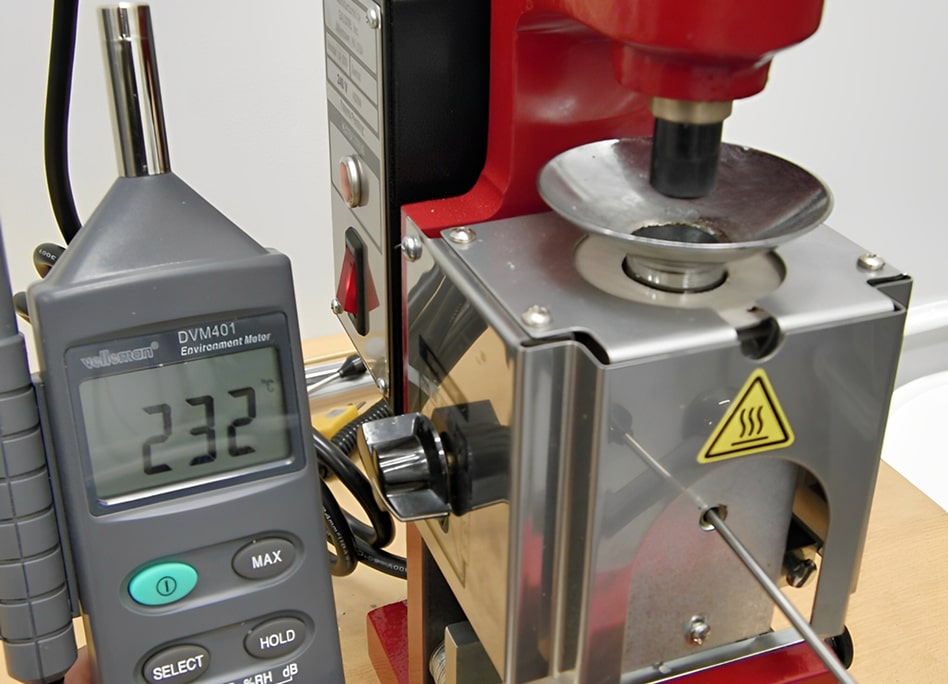

Lid for sugar jar used in the kitchen.

Polypropylene (PP) plastic material, color Red, RoHS compliant.

Customer had a cover mold with internal threads built with an unscrewing device. They approached us and said they were having the following difficulties with the mold:

Richfields team looked into the 3D model of the part, and analyzed the functions of the plastic part produced by this mold. We noticed that the threads are not deep enough and can actually be ejected by forced ejection using an ejector plate. This will make it simpler instead of using an unscrewing device. These are the things that we did:

Very simple changes actually resolved the problems mentioned before by the customer. Richfields was able to achieve the following for the customer: