Family Tool Plastic Injection Molding

Family Tool Plastic Injection Molding is another cost-efficient solution for today’s manufacturers who are seeking to improve their production productivity output without having to sacrifice quality. This is made possible by designing the injection tool so that one mold contains different parts of a product, allowing multiple components to be molded simultaneously in a single cycle.

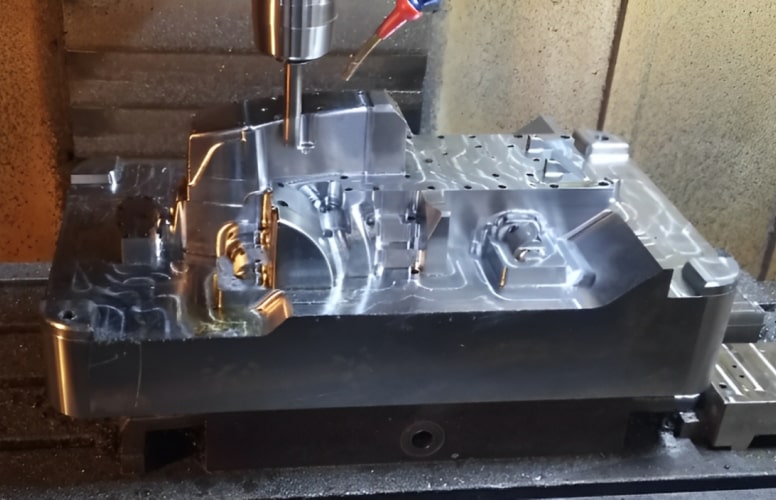

At Richfields, we specialize in designing and producing high-precision family tools tailored to meet the unique needs of each project. Our expertise ensures that each cavity produces parts with consistent quality and dimensional accuracy, making family tooling an ideal choice for complex assemblies or products that require multiple complementary components.