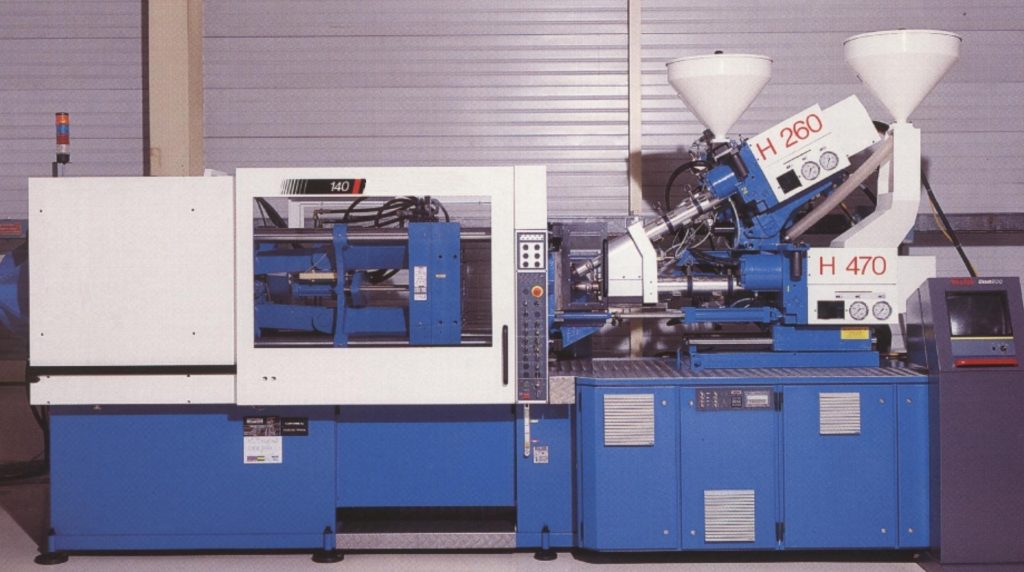

What are the essential part of an injection molding machine?

- Hopper – plastic pellets are being fed through the hopper.

- Barrel – the barrel heats the pallet to liquefy them.

- Reciprocating Screw – this part is in charge of making the liquefied plastic more fit for molding.

- Nozzle – this is the main location where the entire molding process starts.

- Plastic Molding System – this is the part where the molding plated would be placed.

- Cooling Channels – these are the channels that use water, oil, or steam to cool down the molding parts.

The plastic injection molding industry is one of the largest industries in the world, and the centerpiece of all of this is the plastic injection molding machine. Whether it be an injection mold in China or the USA, the plastic injection molding is an important machine that keeps everything running.

Plastic injection molding machines may look complicated for some people, but the whole process is quick, simple, and efficient, which means you would not need to have too many processes to create a product. This speed allows plastic manufacturing companies to be able to produce a high number of quality products in a short span of time. Most plastic injection molding machines require a small amount of staff to operate, which lessens the overall operations cost of many plastic companies, and help them become more profitable as a result. This simple yet efficient machine is responsible for some of the products that people use on a daily basis, which is why it is worth taking a closer look at the inner workings of this machine.

The Hopper

Plastic injection molding machines work by feeding them with plastic pellets, which help produce the products. These plastic pellets will be fed to the part called the hopper. The hopper is where the machine receives its plastic supply, which would then be fed through gravity and melted. This whole process would help create the product in the end.

Barrel

After going through the hopper, the plastic pellets would then go through the barrel, which heats up the pellets to liquify them. This liquified plastic would make them fit for the molding process that would come near the end.

Reciprocating Screw

After going through the barrel and melting, the plastic then goes through the reciprocating screw. The screw is in charge of making the liquified plastic more fit for molding by compressing and conveying it. The plastic goes through various heating bands to create a more consistent liquid material. Most plastic injection molding machines have around three heating bands for an optimal melting process; each band having a higher temperature in each stage.

Nozzle

After going through the reciprocating screw, the melted plastic then goes through a nozzle. The nozzle is the main location in which the plastic is deposited into the sprues, which would help start the entire molding process. The nozzle normally has a temperature that keeps the liquid plastic warm and melted. Once the melted plastic is ready to be deposited into the sprue, the barrel then moves forward into the entry point of the sprues and then injects the liquid plastic. This would then begin the very crucial molding process.

Plastic Molding System

The most important part of the process, the molding system consists of different parts, which include the tie bar, mold plate, movable platen, and stationary platen. This is also the location where the molding plated would be placed, which consists of the ejector pins, cooling channels, cavity, sprue, and the runner systems. The mold system is where the liquid plastic solidifies into the shape of the mold, which would eventually become a part of the finished product.

Most plastic injection molds are usually made out of steel, which would be able to withstand the high temperatures produced by the plastic injection molding machine. Once the liquid plastic has solidified, the mold then opens up and ejects the plastic part into the cooling channels.

It is worth noting that some plastic injection molding machines have different kinds of plate molds. Some machines have a two-plate mold, while others use a three-plate mold. The difference between them is that they produce some parts better than the other. Two-plate molds are best for parts that have gates around the edges, while a three-plate mold is the right mold to use for parts that are gated away from the edges. Both of these plates would be able to produce the best products, as long as you use the right one.

Cooling Channels

These are a series of channels that use water, oil, or steam to cool down the molding parts and make sure that they do not overheat, and are able to produce the parts properly. Most plastic injection molding machines have an automated system that manages this process, which guarantees that everything would be working smoothly. This helps maintain optimal product quality, which a lot of injection molds in China and the plastic industry in the US are known for.

Once the process has been done, manufacturers would do some final touches like cleaning and smoothening the product, along with the final assembly. Once assembled, the product would be going through safety and durability tests, until it is ready for production.

Key Takeaway

The plastic injection molding process may sound complicated, but these series of procedures are very quick and efficient, and would be able to produce the best results that would satisfy clients and consumers alike.