What are the different types of plastics used for flooring?

- Acrylonitrile Butadiene Styrene

- Polyethylene

- Polyvinyl Chloride

- Polypropylene

- Polypropylene + Glass Filled

- Polycarbonate

Overview

This article explores the use of plastics in flooring, highlighting their popularity and benefits, including durability, customization, and sustainability. Key plastics discussed include ABS for interlocking tiles, polyethylene for flexibility and moisture resistance, PVC for versatility, PP for stain resistance and modularity, glass-filled PP for strength, and polycarbonate for unique visual effects. The article also mentions plastic mold injection’s role in creating various flooring components. Richfields Corporation, a Chinese plastic injection molding company, offers premium solutions for flooring needs.

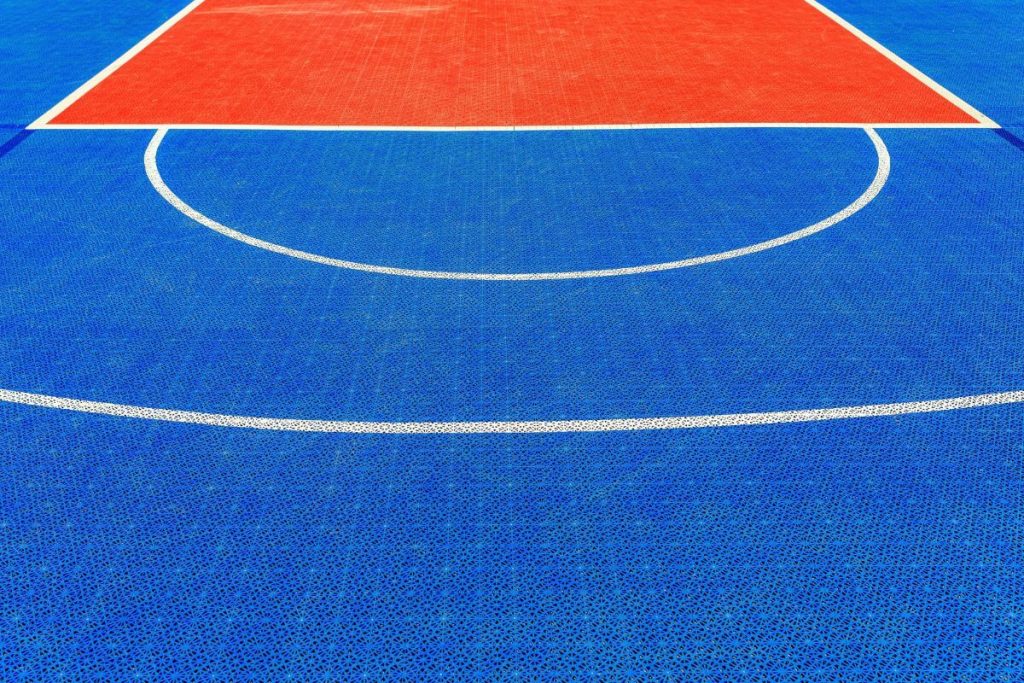

Flooring materials play a crucial role in defining spaces in many kinds of spaces. Amidst this diversity, plastics have emerged as a compelling choice, offering an array of advantages that span aesthetics, resilience, and functionality.

This article takes a deep dive into the types of plastics used for flooring that have surged in popularity across residential, commercial, and industrial sectors. By delving into these plastic options, you’ll uncover the transformative potential they hold for spaces, blending modern design with durability and sustainability.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene (ABS), a thermoplastic polymer, is renowned for its durability and versatility, making it a valuable choice in the flooring industry. This plastic is commonly used for interlocking floor tiles due to its excellent impact resistance and dimensional stability.

ABS tiles, often found in residential and commercial spaces, are designed for easy installation and maintenance. They snap together seamlessly, forming a robust and uniform surface. ABS flooring is highly resistant to moisture, chemicals, and abrasion, ensuring longevity even in high-traffic areas. Additionally, it’s available in various colors and finishes, allowing for customizable and aesthetically pleasing flooring solutions that cater to diverse design preferences. Its combination of strength and adaptability makes ABS an attractive option for flooring applications.

Polyethylene

Polyethylene, a widely used plastic, has made its mark in the flooring industry for its strength and adaptability. This thermoplastic polymer comes in various forms, including high-density (HDPE) and low-density (LDPE) variations.

HDPE offers exceptional durability, often employed in heavy-duty applications like industrial settings and sports facilities. LDPE, on the other hand, prioritizes flexibility and comfort, making it suitable for underlayments or areas requiring cushioning. With its resistance to moisture and chemicals, polyethylene flooring is a reliable choice for environments where resilience and versatility are paramount.

Polyvinyl Chloride

Polyvinyl Chloride (PVC) stands out as a versatile and durable plastic used extensively in flooring applications. Known for its cost-effectiveness and wide-ranging capabilities, PVC flooring comes in various forms, including vinyl tiles, sheets, and luxury vinyl planks (LVP).

PVC tiles offer easy installation and maintenance, making them suitable for both residential and commercial spaces. PVC sheets provide a seamless look and are commonly used in healthcare and educational settings for their hygienic properties. LVP, designed to resemble natural materials like wood or stone, delivers a high-end look without the associated maintenance.

The water-resistant and resilient nature of PVC flooring, along with its customization possibilities and design options, make it a preferred choice for a diverse range of environments.

Polypropylene

Polypropylene (PP) is a thermoplastic polymer widely recognized for its resilience and eco-friendly properties, making it a suitable option for flooring solutions. PP carpet tiles are a common application, known for their durability and stain resistance. These tiles are modular, allowing for easy replacement of damaged sections without the need to replace the entire floor.

PP flooring offers excellent colorfastness and resistance to fading, making it ideal for spaces with high foot traffic. Additionally, its low moisture absorption and resistance to mold and mildew contribute to its longevity. The sustainability aspect of PP, stemming from its recyclability and low environmental impact, aligns with modern demands for eco-conscious materials in flooring.

Polypropylene + Glass Filled

Polypropylene, when reinforced with glass fibers, becomes an exceptionally strong and rigid material, ideal for certain flooring applications. Glass-filled polypropylene boasts impressive mechanical properties, including enhanced tensile strength, stiffness, and dimensional stability.

This composite material is well-suited for raised access flooring systems used in data centers, office spaces, and commercial buildings. The combination of polypropylene’s chemical resistance and the added strength from glass fibers creates a durable and robust flooring solution that can withstand heavy loads and constant foot traffic. Moreover, its resistance to moisture, chemicals, and corrosion makes it a reliable choice for environments where these factors are prevalent. Glass-filled polypropylene flooring offers longevity and stability, contributing to long-term cost-effectiveness in various industrial and commercial settings.

Polycarbonate

Polycarbonate, renowned for its remarkable impact resistance and optical clarity, is a versatile thermoplastic material employed across diverse industries. Though not typically chosen as a primary flooring surface, its unique properties find application in specific and innovative flooring-related scenarios.

Due to its exceptional strength and transparency, polycarbonate can be integrated into certain flooring designs to create transparent or translucent floor panels. These panels offer intriguing visual effects, particularly in spaces where light diffusion or an unobstructed view is desired. Transparent floors, for instance, are used in architectural settings to create striking visual connections between different levels or to bring natural light to lower spaces.

How is Plastic Mold Injection Used in Flooring

Plastic mold injection is used to create tile backing and substrates, providing stability and durability to tiles. This method ensures precise shaping and customization, enhancing functionality and fit.

For accessories like baseboards, thresholds, and transition strips, plastic injection molding crafts detailed components that align with diverse flooring designs.

In cable management, plastic mold injection produces channels, covers, and clips for organizing and hiding wires in commercial and residential spaces. This maintains tidiness, safety, and aesthetics.

For premium plastic injection molding solutions, look no further than Richfields Corporation. As a China-based company, we offer comprehensive services to clients in the U.S.A. Our commitment extends to manufacturing high-quality plastic products, and promptly delivering them to your designated U.S. address. Embrace the power of plastic mold injection with us and elevate your flooring solutions to the next level.

Key Takeaway

This exploration into the array of plastic options used in flooring underscores their capacity to blend functionality, aesthetics, and sustainability. From homes and commercial spaces to industrial environments, the many types of plastic used for flooring offer tailored benefits that cater to specific needs.

From conceptualization to delivery, you can count on us at Richfields to expertly manufacture precision plastic products, ensuring timely and secure transportation to your designated U.S. location. This strategic partnership empowers you to craft superior, high-quality plastic products that cater to the discerning needs of your consumers. Don’t hesitate to contact us today.