Why is injecting molding important in creating battery casing?

- Requires precise manufacturing

- Proven to be very durable

- Provides a cost-effective option for manufacturers

- Offers design flexibility

- Shortens production time

- Reduces waste

- Provides consistent quality

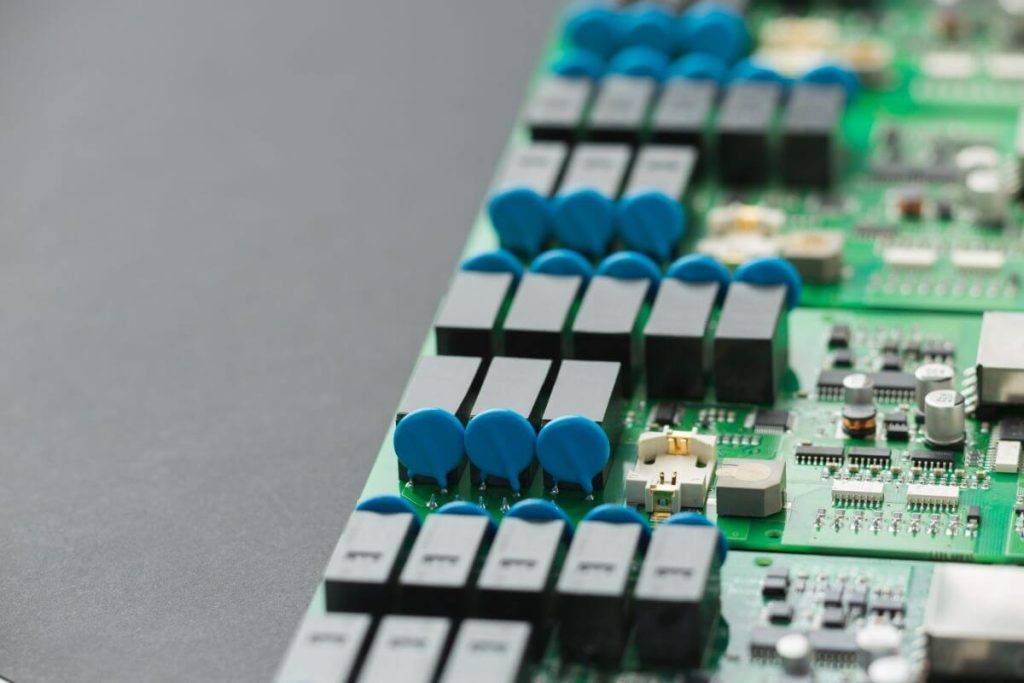

Injection molding has brought about a revolution in the manufacturing industry in various ways. One of its major applications is in the production of battery casings, which are vital components in portable electronic devices that require a source of power. In the United States, injection molding has played a critical role in producing top-notch battery casings that meet the demanding requirements of the electronics industry.

In this blog post, we’ll explore the importance of injection molding in creating battery casings in the USA.

Requires Precise Manufacturing

To guarantee that battery casings perform accurately and are compatible with electronic devices, they require precise manufacturing.

Injection molding is a manufacturing process that involves injecting molten plastic into a mold under high pressure. The mold is typically made from metal and is designed to form the plastic into a specific shape. The molten plastic is then allowed to cool and solidify within the mold, after which the mold is opened, and the newly formed plastic part is ejected.

The precision of injection molding is particularly useful when it comes to manufacturing battery casings. The consistent shape and size of the casings ensure a secure fit for the batteries within the device, preventing damage from movement or vibration. Moreover, the precise manufacturing process ensures that the battery casing meets the exacting specifications of the electronic device, such as size, shape, and even color.

Proven to be Very Durable

Battery casings need to be durable to withstand the daily wear and tear of usage. With injection molding, it’s possible to produce strong and robust battery casings that can resist impacts, temperature fluctuations, and chemical exposure.

Injection molding allows for the selection of plastic materials that can be customized to meet the durability requirements of a particular battery casing. For instance, if a battery casing is expected to withstand high impact, it can be manufactured using a plastic material that has higher toughness and tensile strength. Alternatively, if the battery casing will be exposed to extreme temperatures, it can be created using plastic that can withstand the temperature range.

Moreover, injection molding enables the creation of a uniform and homogenous material structure in the battery casing, resulting in consistent and predictable mechanical properties. This uniformity ensures that the casing can withstand the mechanical stresses associated with everyday use and maintain its structural integrity over time.

Provides a Cost-Effective Option for Manufacturers

Injection molding is an economical method of manufacturing that enables the mass production of battery casings at a lower cost per unit. The molds used in injection molding are reusable, resulting in a decreased production cost with each subsequent run.

The process is also highly automated, which means that labor costs are minimal, leading to even more savings in the overall production cost.

Offers Design Flexibility

One of the main advantages of injection molding is the ability to create highly complex shapes and designs with precise details and consistency. This flexibility allows manufacturers to produce battery casings in a wide range of shapes and sizes that can fit into various electronic devices with different dimensions and requirements.

Moreover, the molds used in injection molding can be customized to produce battery casings with specific features, such as internal cavities, ribs, or undercuts, which may be necessary for some applications. These design elements can improve the durability, heat dissipation, and overall functionality of the battery casing, making it more suitable for specific electronic devices.

Additionally, injection molding allows for the production of multiple cavities in one mold, meaning that several battery casings can be produced simultaneously in a single production run. This capability reduces the production time and cost per unit, making injection molding a highly efficient and cost-effective method for mass production.

Shortens Production Time

The injection molding process is a rapid and efficient manufacturing method that enables the production of battery casings within a short timeframe. The production cycle is usually brief, and a large number of parts can be produced per cycle. Moreover, the molds used in injection molding can be designed for multi-cavity production, further increasing the number of parts produced per cycle.

Reduces Waste

Injection molding results in minimal waste compared to other manufacturing processes. The plastic used in injection molding is precisely measured and injected into the mold, ensuring minimal waste generation.

Moreover, any excess plastic produced during the production process can be recycled and reused in subsequent production runs, further reducing the amount of waste generated.

Provides Consistent Quality

Injection molding guarantees consistent quality in the final product, which is essential in creating battery casings that meet industry standards. The process involves strict control measures to ensure that each product produced meets the required specifications.

The molds used in injection molding are regularly maintained and inspected to ensure that they are in optimal condition, further ensuring the consistency of the final product.

Key Takeaway

This article stressed the importance of injection molding in battery casing in the USA. This process has allowed for the creation of high-quality, durable, and precise battery casings that meet the requirements of the electronics industry.

As technology continues to evolve, it is expected that injection molding will continue to play a crucial role in the production of battery casings and other essential components in the electronics industry.

Here at Richfields, we can help you produce the best battery cases through injection molding. We offer a variety of services from large-part injection molding to plastic mold making. Contact us today!