Overview

- This article provides an in-depth look at hot runner injection molding, a technology used to enhance the efficiency and precision of plastic part production.

- It covers key components such as nozzle bodies, manifolds, inlets, and heater technology, highlighting their roles in maintaining molten plastic flow and reducing waste.

- Additionally, it explores the diverse applications of hot runner systems across industries, from automotive to medical equipment.

China hot runner injection molding is a sophisticated manufacturing process widely used for producing high-quality plastic parts with enhanced efficiency. This technique involves using a heated runner system to keep the plastic molten and flowing, eliminating the need for a cold runner and reducing material waste.

This technology is employed to achieve superior precision, faster cycle times, and cost-effective production for various applications, from automotive components to consumer electronics.

Understanding it is essential for optimizing your manufacturing processes and achieving high-performance outcomes.

What is Hot Runner Technology?

Hot runner technology is an advanced system used in plastic injection molding that maintains the plastic material in a molten state throughout the molding process. By keeping the plastic hot and flowing continuously through heated channels, it is delivered directly into the mold cavities. This enhances efficiency and reduces waste, as the plastic does not solidify within the runner channels.

In contrast to cold runner systems, which allow the plastic to cool and solidify between each molding cycle, creating excess material that must be removed and recycled, hot runner systems prevent this waste. It ensures a more streamlined production process by maintaining the plastic’s temperature.

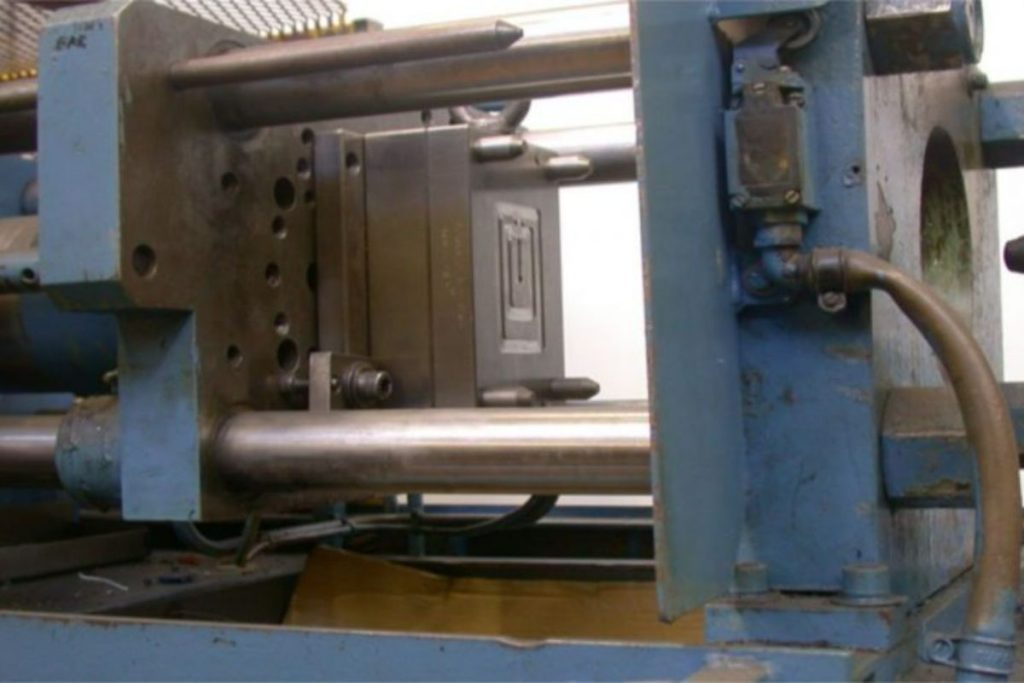

Parts of a Hot Runner Injection Molding

The key components of a hot runner injection molding system work together seamlessly to optimize production and ensure high-quality plastic parts.

Nozzle Body

Also known as the drop, the nozzle body is a crucial component of this system. It is the direct conduit through which molten plastic is delivered into the mold cavities. It maintains the temperature of the molten plastic, preventing it from solidifying before reaching the mold.

Designed to withstand high temperatures, the nozzle body comes in various styles, including threaded and valve nozzles, each tailored for specific applications.

Manifolds

Manifolds distribute molten plastic from the inlet to the individual nozzles that feed the mold cavities. Engineered with precision, they feature flow channels designed to ensure balanced and efficient delivery of the plastic melt to each nozzle, minimizing waste and optimizing part quality.

They are made from hardened tool steel and manufactured using techniques, such as vacuum brazing to create smooth, sweeping flow paths that avoid sharp corners or holding areas that could impede the flow.

Inlet

The inlet is the entry point for molten resin into the injection nozzle during the molding process. It facilitates the efficient transfer of molten plastic from the manifold to the heated nozzles, ensuring the material remains molten as it flows into the mold cavities. This component is vital for maintaining a consistent and controlled flow of resin, which directly affects the quality and precision of the molded parts.

Heater Technology

Heater technology maintains the molten state of plastic as it travels through the system. It employs various heating methods, such as heater bands, plates, or brazed-in heaters, to ensure that the temperature of the molten plastic remains consistent throughout the injection process.

By precisely controlling the heat applied to the manifold and nozzles, it enhances the quality of the molded parts, improving their surface finish and dimensional accuracy.

Applications of Hot Runner System

Hot runner systems have revolutionized the injection molding industry, enabling the efficient production of high-quality plastic parts across a wide range of applications.

Automobile

This technology enables manufacturers to create intricate parts such as interior trim panels, fenders, and bumpers with improved precision and efficiency. As China’s automotive sector continues to grow, the adoption of hot runner technology allows for faster production cycles and the ability to meet the increasing demand for complex and lightweight components, contributing to the overall efficiency and sustainability of automotive manufacturing in the region.

Furniture

It allows the efficient production of high-quality plastic components used in various furniture applications. This allows manufacturers to create intricate designs and durable parts, such as chair bases, table components, and decorative elements, with enhanced precision and minimal waste.

As a result, furniture manufacturers can meet the growing demand for customized and complex designs while maintaining high production speeds and reducing material costs, ultimately contributing to the industry’s overall efficiency and sustainability.

Medical Equipment

High standards for quality are essential in medical equipment like syringes. The ability to maintain consistent temperatures throughout the molding process reduces the risk of defects and enhances the overall quality of the products.

Additionally, the hot runner system minimizes material waste and shortens cycle times, allowing manufacturers to meet the increasing demand for medical supplies efficiently.

Consumer Goods

Unlike cold runner systems, this technology allows for the efficient production of complex cellphone components with intricate designs and tight tolerances. The continuous heating of the molten plastic prevents premature solidification, enabling the molding of thin-walled housings and intricate features that are challenging to achieve with cold runners.

Key Takeaway

China hot runner injection molding has transformed the plastic manufacturing landscape, offering an efficient and innovative approach to producing high-quality plastic parts. As the industry continues to evolve, the adoption of this system is expected to grow, meeting the increasing demands for precision and sustainability in manufacturing.

At Richfields Corporation, we’re committed to delivering the best to our clients. Our meticulous maintenance ensures our equipment operates at peak performance, producing exceptional plastic products. As your trusted partner, we prioritize quality and efficiency in every aspect of our work. Contact us today to discuss your project and learn more about our precision plastic injection molding services.