Have you ever thought about how plastic bottles are made?

What about your children’s favorite toys?

Or maybe, the single-use syringes you see at the hospital?

Well, all of these are actually made through a manufacturing process called plastic injection molding in China.

Plastic injection molding is a process that creates products by injecting melted plastic into a mold. The mold is then subjected to extreme pressure and is subsequently cooled down by a blast of either water or oil. As you can see, there are a number of processes that the product must go through before it reaches its final form. These steps all create their own waste that can harm the environment. Plastic itself is a non-biodegradable material that could cause real complications to the Earth if not properly disposed of.

In order to combat this, plastic injection molding companies are doing their part to switch to a more sustainable type of manufacturing. Sustainable manufacturing aims to lessen the negative impact these different processes have on the environment. It also aims to minimize the amount of energy and natural resources used in the manufacturing and transportation of these goods.

Interested in learning more? Read on to find out why sustainable manufacturing is important and how plastic injection molding companies have adapted to it.

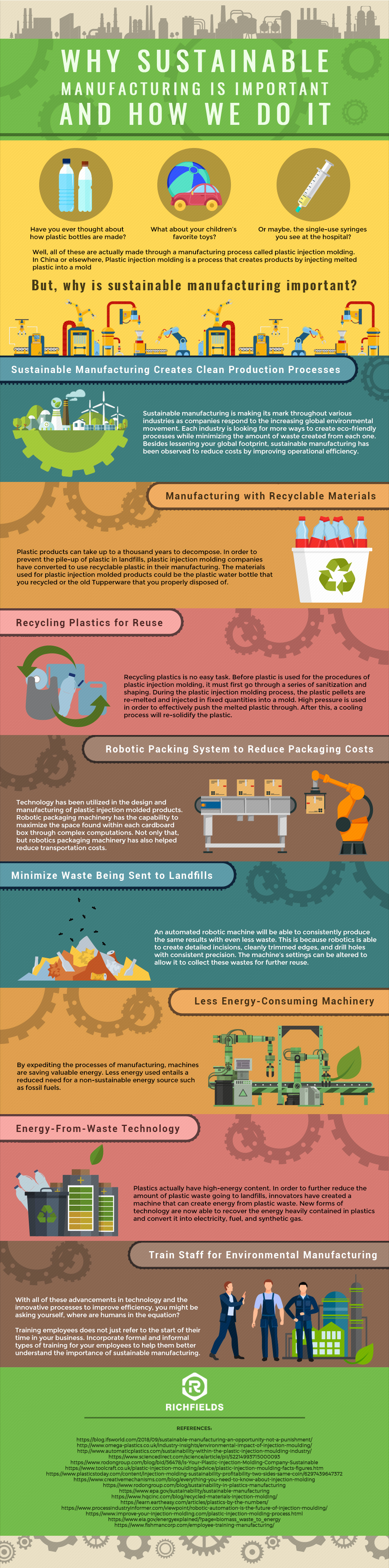

Sustainable Manufacturing Creates Clean Production Processes

Sustainable manufacturing is making its mark throughout various industries as companies respond to the increasing global environmental movement. Sustainability is now becoming a key component in the strategies and operations of businesses in order to further develop public trust as well as to increase their competitive advantage. Each industry is looking for more ways to create eco-friendly processes while minimizing the amount of waste created from each one.

Besides lessening your global footprint, sustainable marketing also helps you in terms of financial costs. Sustainable manufacturing has been observed to reduce costs by improving operational efficiency. For example, in the plastic injection molding industry, robotics is utilized to fit the most amount of products in one box. This reduces the number of cardboard boxes used for packaging, which leads to less space used inside of a delivery truck, which reduces the number of trucks needed to transport the goods.

The advantages of switching to a more sustainable type of manufacturing can greatly help a company in the long run. Not only will overall efficiency be improved upon, but you will also be able to protect your reputation as well as build public trust. The long-term effects of converting to this type of manufacturing will solidify your company as a global competitor in your respective industry. Read on to learn about how plastic injection molding is doing its part to convert to a more sustainable style of manufacturing.

Manufacturing with Recyclable Materials

Plastic products can take up to a thousand years to decompose. In order to prevent the pile-up of plastic in landfills, plastic injection molding companies have converted to use recyclable plastic in their manufacturing. The materials used for plastic injection molded products could be the plastic water bottle that you recycled or the old Tupperware that you properly disposed of. These are collected and sent to facilities in order to be melted and formed into recycled plastic pellets. Two of the more common types of recyclable materials used in plastic injection molding are polypropylene and polyethylene terephthalate (PET).

Number 1: PET (Polyethylene Terephthalate)

The type of plastic that water bottles and soda bottles are made out of is called polyethylene terephthalate (PET). They are one of the most used types of plastics for consumer products. These items are usually created for single-use and are imperative to be recycled in order to be utilized to create new items. This would effectively increase the life span of these plastics but in a different form.

Number 5: PP (Polypropylene)

Hard products made of plastic such as pails, plastic bottle caps, yogurt containers, and straws are made of a plastic called polypropylene (PP). It can also be turned into a thin plastic liner such as those found within cereal boxes. This is a lightweight but tough type of plastic that has great heat resistance. It is strong enough to act as a barrier against grease, moisture, and chemicals.

These types of recyclable materials undergo multiple processes to sanitize and reuse them for the creation of new products.

Recycling Plastics for Reuse

Recycling plastics is no easy task. Before plastic is used for the procedures of plastic injection molding, it must first go through a series of sanitization and shaping. One of the challenges of using post-consumer containers is that the chemicals that it previously held could have absorbed into the plastic. This is the case for old containers used for pest control. These would have to be properly sanitized with the use of a special mixture of chemicals before being cleared to be used. Only then can it start the shaping process.

First, the plastic is fed into a grinder in order to be turned into little pieces. The tiny pieces of plastic are then fed to a machine that melts it through the extreme heat created by turning screws and heaters along the barrel. The heated polymer is then forced through an opening that shapes it into the desired pellets. After cooling, the pellets will be ready for use.

During the plastic injection molding process, the plastic pellets are re-melted and injected in fixed quantities into a mold. These pellets could be made of a combination of two different types of recycled plastic. High pressure is used in order to effectively push the melted plastic through. After this, a cooling process will re-solidify the plastic.

Besides the reuse of recyclable plastics, another advantage of sustainable manufacturing in the plastic injection molding industry is its ability to reduce costs.

Robotic Packing System to Reduce Packaging Costs

Technology has been utilized in the design and manufacturing of plastic injection molded products. In order to fully integrate into a sustainable manufacturing system, companies needed to think of a way to improve efficiency in the final step, packaging & transportation. Enter, robotic packaging machinery.

Reducing Cardboard Waste

Robotic packaging machinery has the capability to maximize the space found within each cardboard box through complex computations. It is specially designed to accept any type of box and has no need for any human facilitation. It will open, fill up, seal, and label each box at intense speeds. For example, certain companies have gone from 750 parts in a box to a whopping 4500 parts per box through a robotic packaging system.

Reducing Transportation Costs

Not only that, but robotics packaging machinery has also helped reduce transportation costs. By using 15,000 fewer cardboard boxes on average, significantly fewer trucks needed to be on the road. This means that fewer trucks are emitting carbon dioxide into the atmosphere. It also means that plastic injection molding companies have reduced their transportation costs.

Another way that technology aids plastic injection molding companies in their quest to achieve sustainable manufacturing are the minimization of waste being sent to landfills.

Minimize Waste Being Sent to Landfills

Robotic automation has been able to create designs that maximize the use of materials in plastic injection molding, which has helped become a prime example of sustainable manufacturing in the industry. Unlike human employees who may cause some inconsistencies in the manufacturing of a product, an automated robotic machine will be able to consistently produce the same results with even less waste.

This is because robotic machines are able to create detailed incisions, cleanly trim edges, and drill holes with consistent precision. Similar to how robotics aid in improving the maximization of cardboard boxes, they can also pinpoint and graph the specific parts that can be created from the available material. The machine’s settings can be altered to allow it to collect these wastes for further reuse.

Advancements in technology have been a huge part of the waste-saving and energy-saving properties of the industry.

Less Energy-Consuming Machinery

Technology has aided a ton in company efforts to convert to sustainable manufacturing. This is caused by expediting the processes of manufacturing, the machines are also saving valuable energy. Less energy being used entails a reduced need for a non-sustainable energy source such as fossil fuels. As robotics are automated in the plastic injection molding industry, they can work at a faster pace compared to human employees. They also have the ability to work 24 hours a day without the need for a break or a vacation.

In order to reduce the cycle times for each batch, the machine calculates and regulates the heating, casting, and cooling processes. This has completely taken away the need to estimate for any kind of process and has also taken away the downtime that used to allow for batches to cool enough to be handled by humans. By speeding things up, injection molding machines now use 50% less energy than it used to. Which means that faster cycle times lead to cheaper manufacturing and more energy-saving processes.

Besides saving up on energy, did you know that there are machines that can actually create energy from wastes?

Energy-From-Waste Technology

In order to further reduce the amount of plastic waste going to landfills, innovators have created a machine that can create energy from plastic waste. Plastics actually have high-energy content. New forms of technology are now able to recover the energy heavily contained in plastics and convert it into electricity, fuel, and synthetic gas. The process called “energy recovery” is quickly becoming recognized as one of the legitimate sources of renewable energy. Plastic wastes now have the ability to power up to 13 million homes.

In terms of plastic injection molding, utilizing energy-from-waste production leads to less waste making its way to a landfill. More and more plastic injection molding companies are converting into a “Landfill-Free Facility”. Every type of plastic waste is either ground up and reused or converted into different forms of energy.

Besides creating a more sustainable form of manufacturing through technology and more efficient processes, your employees must also understand its importance in order to help you create more innovative and sustainable practices.

Train Staff for Environmental Manufacturing

With all of these advancements in technology and the innovative processes to improve efficiency, you might be asking yourself, where are humans in the equation?

Well, no company would be complete without its employees. Training employees does not just refer to the start of their time in your business. It should be a continuous process in order to form the most capable employees. Incorporate formal and informal types of training for your employees to help them better understand the importance of sustainable manufacturing. Properly teach them how to use these new types of machinery in order to make more knowledgeable and aware employees.

Now you know why sustainable manufacturing is important and how it is applied to the plastic injection molding industry. Take note of these steps in order to help convert your business into a sustainable one.

Key Takeaway

The step-by-step process of plastic injection molding in China can become more sustainable by choosing to reuse recyclable materials. This can be done more efficiently with the help of advanced technology that aims to reduce the waste created in the manufacturing process. Less waste means fewer materials going into a landfill.

With the help of robotics, transportation and packaging costs can be greatly reduced due to the process’ optimization. The development of technology has also created more sustainable machinery that uses less energy than its previous counterparts, reducing the number of greenhouse gases being exposed to the world. New forms of technology can also convert waste into energy, making use of these non-biodegradable materials for a better cause. And finally, companies are now actively trying to educate their employees regarding sustainable manufacturing and why it should be one of their priorities.

Sustainable manufacturing is possible for the processes of plastic injection molding in China. Now, you can further do your part by upgrading your own manufacturing processes in order to cater to a more sustainable lifestyle.

Do your part to save the Earth, choose sustainability!